Flame-retardant mechanical foam

A foam and flame retardant technology, applied in coatings, textiles and papermaking, polyurea/polyurethane coatings, etc., to achieve good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

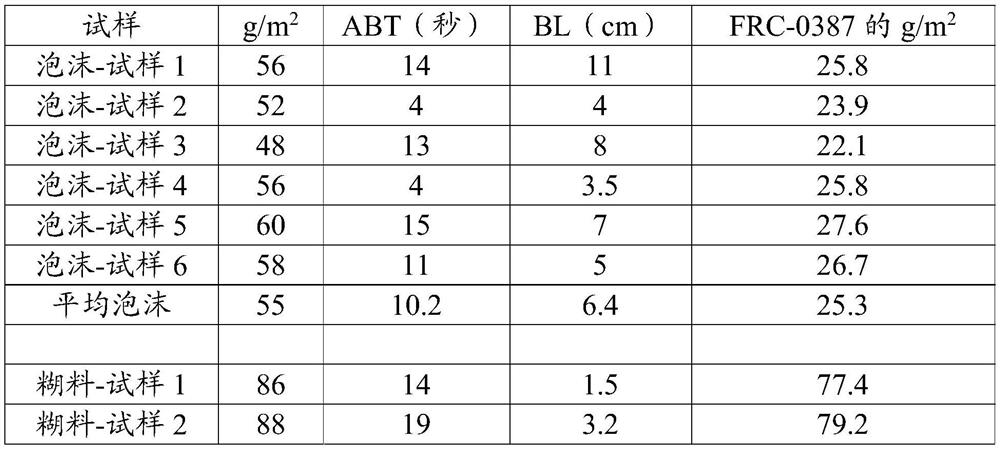

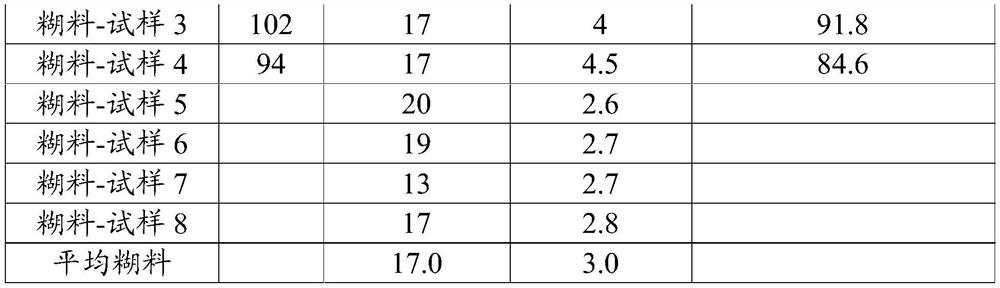

[0046] Example 1: Aeronautical Test Method - Comparison with Paste Coatings

[0047] A mixture was prepared containing 50 parts Permutex RU-92-213 (polyurethane dispersion, available from StahlEurope BV), 50 parts Eagleban FRC-0387 (product containing uncoated diammonium hydrogen phosphate as flame retardant, available from StahlEurope BV) from Stahl Europe BV), 7 parts of a 30% aqueous solution of ammonium stearate and 1 part of Permutex XR-13-554 (polycarbodiimide crosslinker, available from Stahl Europe BV). The mixture was mechanically foamed and the resulting foam was applied to aerospace fabrics (hydroentanglement and fiber production). The foam was then dried at 80°C for 4 minutes, and then at 120°C for 2 minutes in order to speed up drying.

[0048] As a reference, a paste containing Eagleban FRC-0387, a product containing diammonium hydrogen phosphate as a flame retardant, available from Stahl Europe BV, was used. The reference was applied to aerospace fabrics (hydr...

Embodiment 2

[0054] Example 2: Upholstery Test Method - Comparison with Collapsible Foam

[0055] A mixture was prepared containing 50 parts Permutex RU-92-213 (a polyurethane dispersion available from Stahl Europe BV), 50 parts Eagleban FRC-0387 (a non-coated diammonium hydrogen phosphate containing as flame retardant (available from Stahl Europe BV) and 7 parts of a 30% aqueous solution of ammonium stearate. The mixture was mechanically foamed to a density of 200 g / L by mixing at high speed with a stirrer, and the resulting foam was coated on a 100% polyester based velour textile with a layer thickness of 100 g / m 2 amount of dry layer. The foam was then dried at 80°C for 4 minutes, and then at 110°C for 2 minutes in order to speed up drying. The solids content of Permutex RU-92-213 is 60%. Eagleban FRC-0387 has a solids content of 52.5%, of which 7.5% is polymer resin and 45% is from fillers, including flame retardant components. The mixture of 50 parts Permutex RU-92-213 and 50 part...

Embodiment 3

[0059]Example 3: Furniture Upholstery Test Method - Comparison with Collapsible Foam

[0060] 50 parts Permutex RU-92-213 (polyurethane dispersion, available from Stahl Europe BV), 50 parts Eagleban FRC-0387 (a product containing uncoated diammonium hydrogen phosphate as flame retardant, available from Stahl Europe BV) were prepared obtained), a mixture of 7 parts of a 30% aqueous solution of ammonium stearate and 1 part of Permutex XR-13-554 (polycarbodiimide crosslinker, available from Stahl Europe BV). The mixture was mechanically foamed to a density of 200 g / L and the resulting foam was coated with a blade on a 100% polyester based textile with a layer thickness of 0.95 mm. The foam was then dried at 80°C for 4 minutes, followed by 2 minutes at 120°C for faster drying. The solids content of Permutex RU-92-213 is 60%. The solids content of Permutex XR-13-554 is 100%. Eagleban FRC-0387 has a solids content of 52.5%, of which 7.5% is polymer resin and 45% is from fillers, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com