Oiling process in viscose fiber post-treatment refining process

A viscose fiber and process technology, applied in the field of oiling technology, can solve the problems of poor oiling uniformity of viscose fiber, and achieve the effects of improving textile processing performance, facilitating recycling and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

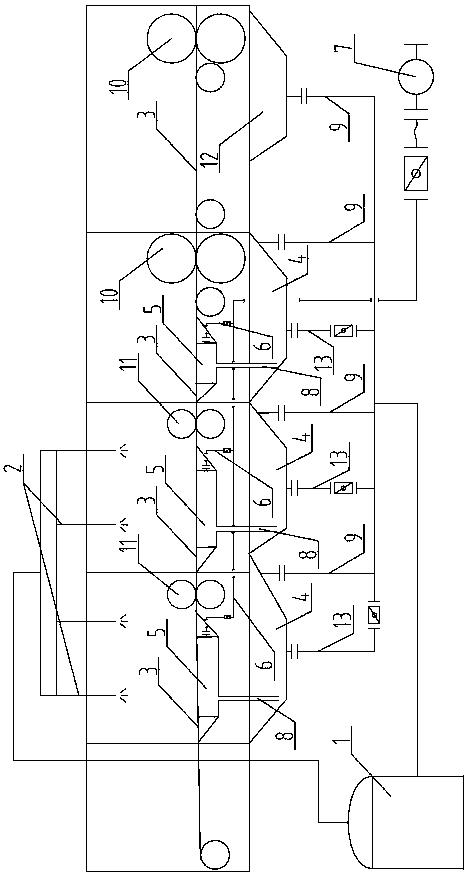

[0033] An oiling process in the post-treatment scouring process of viscose fibers, comprising the following process steps:

[0034] A, in the oiling section of the viscose fiber refining machine, a vacuum liquid suction box 5 is set on the lower surface of the chain plate conveyor belt 3, and the side wall of the vacuum liquid suction box 5 is connected to the vacuum pump 7 through the vacuum suction pipeline 6; The bottom of the vacuum liquid suction box 5 extends into the liquid seal return tank 4 below through the oil agent working fluid return pipeline 8, and the side wall of the liquid seal return flow tank 4 is connected to the oil agent working fluid through the oil agent working fluid circulation recovery pipeline 9. Tank 1;

[0035] B, the viscose fiber on the chain plate conveyor belt 3 is transported to the oiling section, and the oil agent working fluid spray device 2 above the viscose fiber will spray the oil agent working fluid in the oil agent working fluid stor...

Embodiment 2

[0040] An oiling process in the post-treatment scouring process of viscose fibers, comprising the following process steps:

[0041]A, in the oiling section of the viscose fiber refining machine, a vacuum liquid suction box 5 is set on the lower surface of the chain plate conveyor belt 3, and the side wall of the vacuum liquid suction box 5 is connected to the vacuum pump 7 through the vacuum suction pipeline 6; The bottom of the vacuum liquid suction box 5 extends into the liquid seal return tank 4 below through the oil agent working fluid return pipeline 8, and the side wall of the liquid seal return flow tank 4 is connected to the oil agent working fluid through the oil agent working fluid circulation recovery pipeline 9. Tank 1;

[0042] B, the viscose fiber on the chain plate conveyor belt 3 is transported to the oiling section, and the oil agent working fluid spray device 2 above the viscose fiber will spray the oil agent working fluid in the oil agent working fluid stora...

Embodiment 3

[0050] An oiling process in the post-treatment scouring process of viscose fibers, comprising the following process steps:

[0051] A, in the oiling section of the viscose fiber refining machine, a vacuum liquid suction box 5 is set on the lower surface of the chain plate conveyor belt 3, and the side wall of the vacuum liquid suction box 5 is connected to the vacuum pump 7 through the vacuum suction pipeline 6; The bottom of the vacuum liquid suction box 5 extends into the liquid seal return tank 4 below through the oil agent working fluid return pipeline 8, and the side wall of the liquid seal return flow tank 4 is connected to the oil agent working fluid through the oil agent working fluid circulation recovery pipeline 9. Tank 1;

[0052] B, the viscose fiber on the chain plate conveyor belt 3 is transported to the oiling section, and the oil agent working fluid spray device 2 above the viscose fiber will spray the oil agent working fluid in the oil agent working fluid stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com