Multifunctional stress dispersing type expansive concrete steel pipe pile and construction method

A technology of expanded concrete and stress dispersion, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of small surface friction of ordinary steel pipe piles, difficult to control construction quality, and concealed construction process, so as to improve the pullout resistance. Anti-floating performance, improve the effect of anti-lifting and anti-floating and bearing capacity, and strengthen the anti-lifting and anti-floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

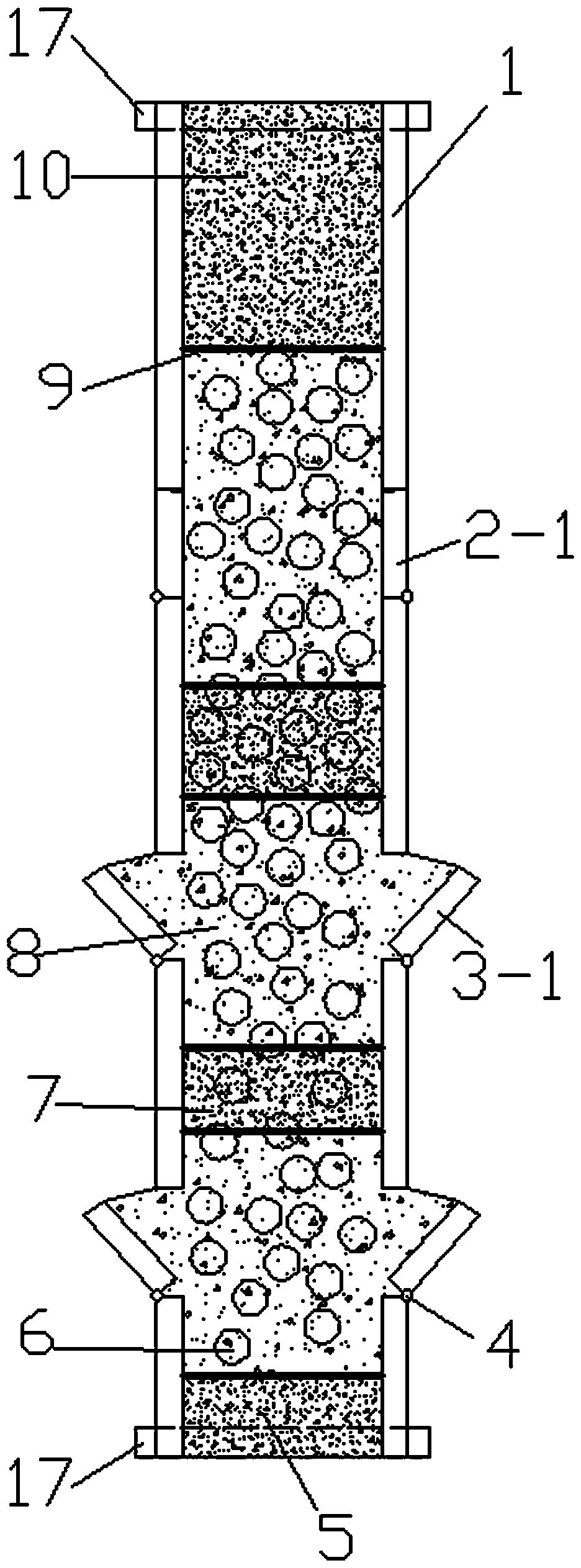

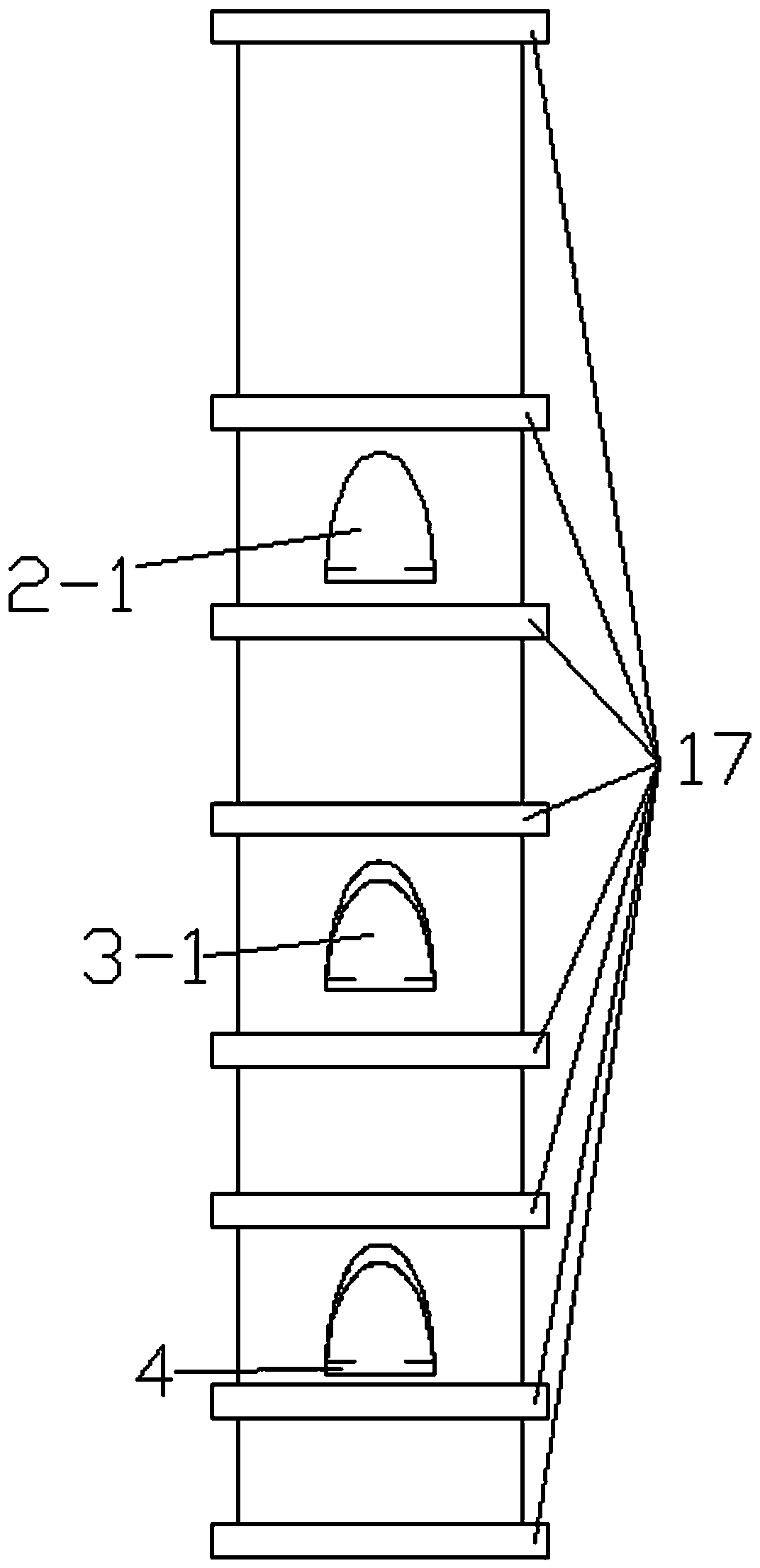

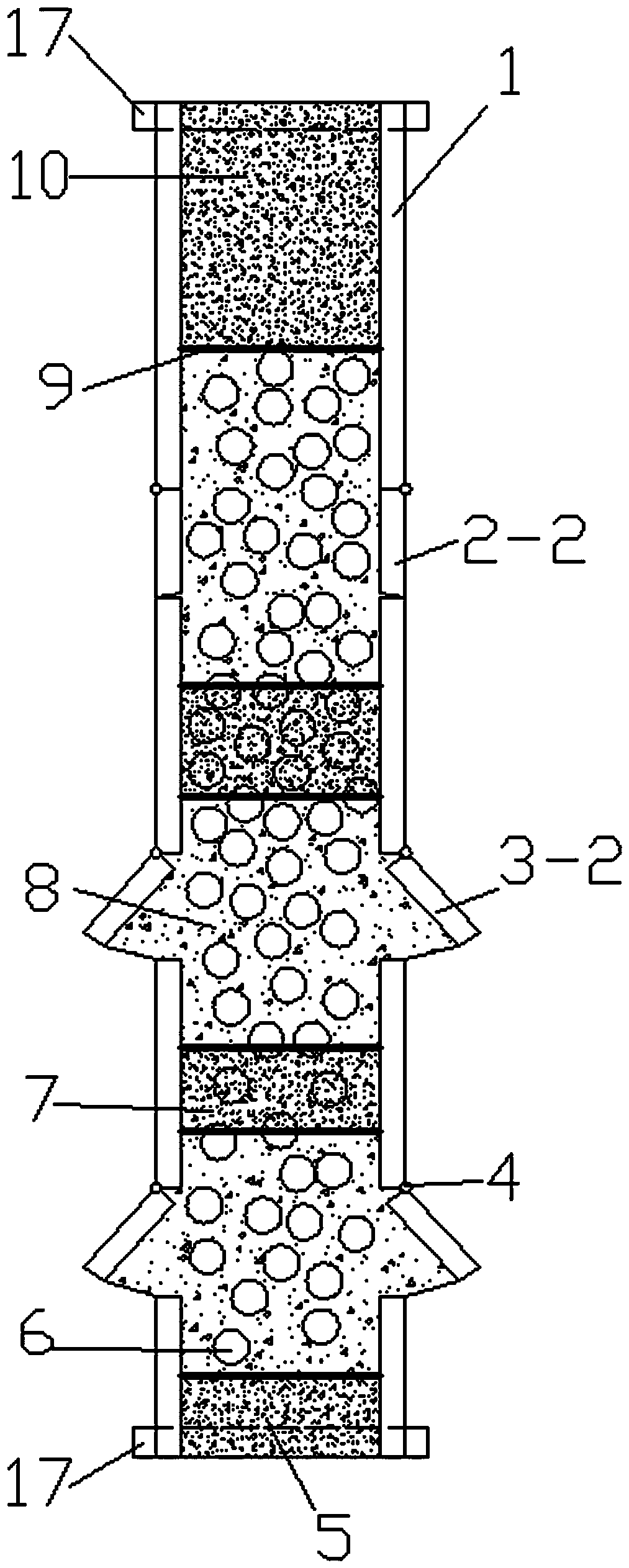

[0049] like Figure 1-9 As shown, a multi-functional stress dispersion type expanded concrete steel pipe pile, which includes a steel pipe pile 1, the steel pipe pile 1 is the main structure, and holes are evenly distributed on the side wall of the steel pipe pile 1, so that The position where the hole is located is hinged with a wing plate through the wing plate rotation shaft 4; the bottom of the steel pipe pile 1 is poured with a back-sealing concrete 5, and the section of the length of the steel pipe pile 1 where the wing plate is located is poured with an expanded concrete 8. Ordinary concrete 7 is poured between adjacent expansive concrete 8 , and sealing concrete 10 is poured on the top of the steel pipe pile 1 . By adopting the above-mentioned steel pipe pile 1, different forms of stress-distributing expansion bodies are formed near the holes, so that the pressure or tension can be evenly distributed, and can be applied to different foundations. While giving full play...

Embodiment 2

[0064] like Figure 1-4 , the upper-end open flange steel pipe pile has good bearing capacity and is suitable for construction under general geological conditions. The lower-end open flange steel pipe pile has good anti-lifting and anti-floating performance and can be used for construction in groundwater environments.

[0065] The construction method of any multifunctional stress dispersion type expanded concrete steel pipe pile is characterized in that it comprises the following steps:

[0066] Step 1: The holes in the pile body are laid out. According to the geological conditions and the bearing capacity requirements of the single pile, a wing plate matching the shape and size of the hole is set on the pile body, and the steel pipe pile 1 is connected to the steel pipe pile 1 through the rotation axis 4 of the wing plate;

[0067] Step2: Back cover, use back cover concrete 5 for back cover, and add a partition plate 9;

Embodiment 3

[0073] like Figure 5-7 , which mainly introduces the general construction method of the crescent-shaped, herringbone-shaped and segmented spiral hole steel pipe piles of the present invention. This kind of steel pipe piles is suitable for construction under general geological conditions.

[0074] Step1: Pile body hole layout, according to geological conditions and single pile bearing capacity requirements, choose to set crescent-shaped holes 11, herringbone holes 12 or segmented spiral holes 13 holes in the pile body;

[0075] Step2: Drill the hole, drill the hole to the design depth, and immediately lower the pipe, and prevent the hole wall from collapsing during the lowering process;

[0076] Step3: Back cover, use back cover concrete 5 for back cover, and proceed to the next step when the concrete strength reaches 75%;

[0077] Step4: Pile body material pouring, the full length can be poured with expansive concrete or a certain amount of crushed stone6, until the grouting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com