A method for manufacturing semiconductor packaging devices by laser

A technology for packaging devices and semiconductors, used in semiconductor/solid-state device manufacturing, manufacturing tools, laser welding equipment, etc., can solve problems such as failure to achieve device design goals, high process complexity, and poor process accuracy, saving space. , The effect of low production complexity and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

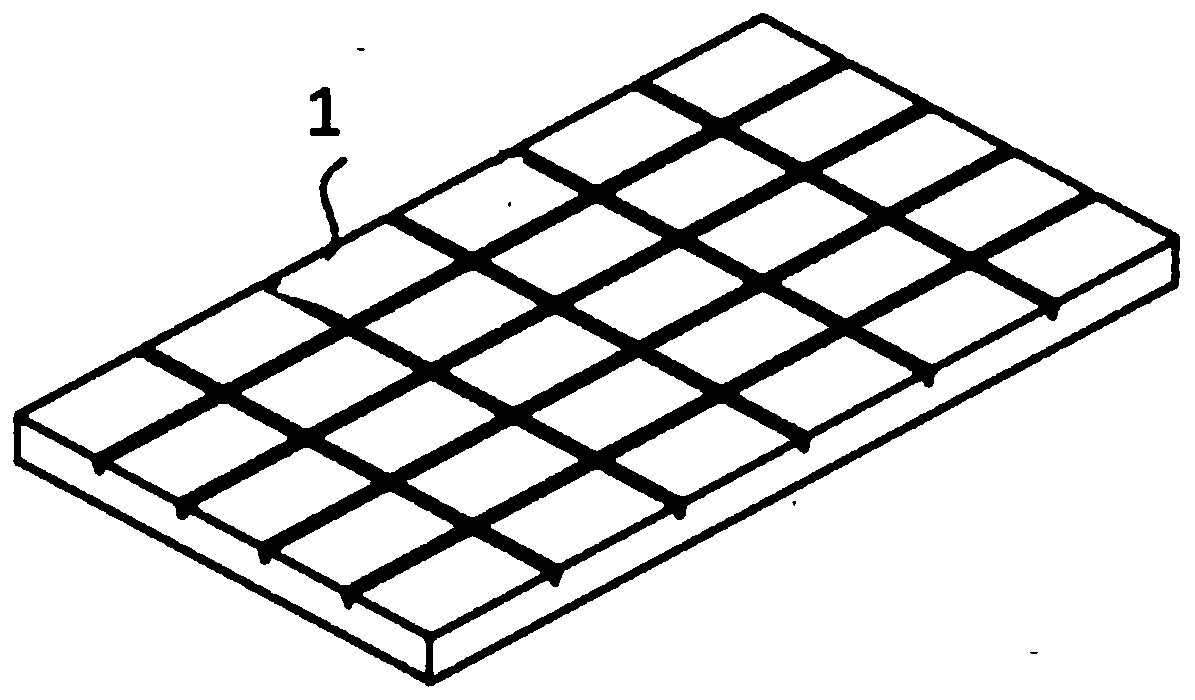

[0030] Such as figure 1 Shown, a kind of laser manufactures the method for semiconductor packaging device, comprises the following steps:

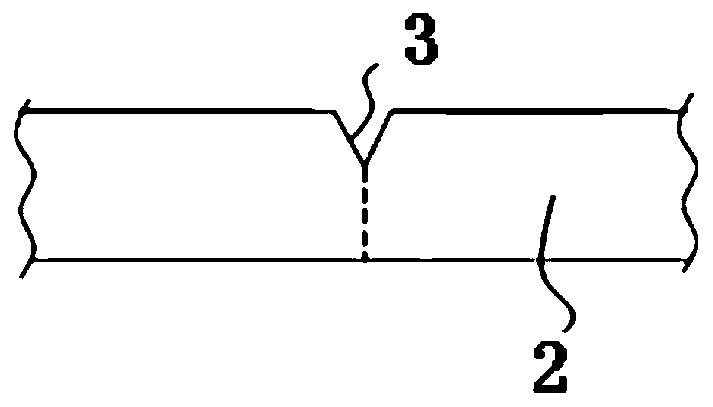

[0031] Step 1, such as figure 1 and 2 As shown, grooves 3 are cut on the top surface of the ceramic substrate 2. The cross section of the grooves 3 is V-shaped. The grooves 3 include several horizontal and several vertical ones. Several component units 1 are formed by dividing the grooves 3. Define The module unit 1A side is opposite to the B side.

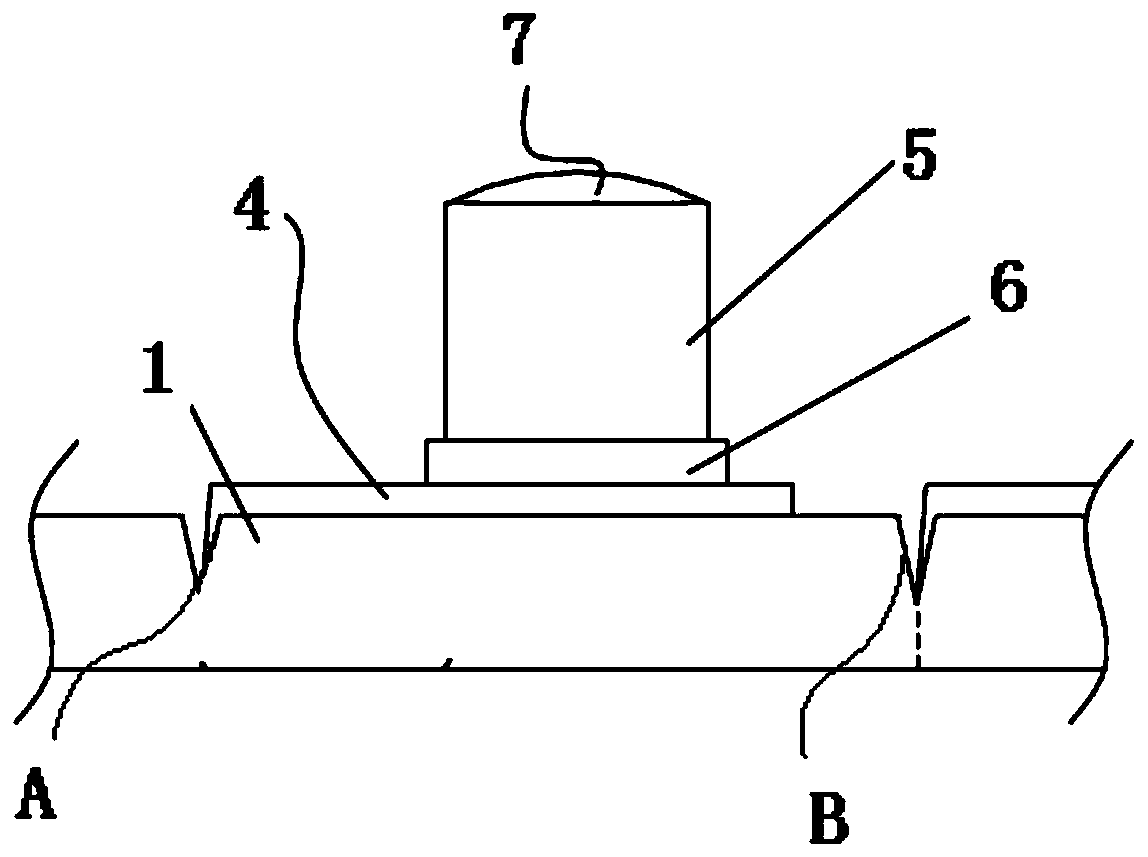

[0032] Step 2, such as image 3 As shown, the top surface of the assembly unit 1 is coated with conductive paste, and extends to the side of the assembly unit 1A to form the lower conductive path 4 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com