Lithium ion battery

A lithium-ion battery and electrolyte technology, which is applied in the direction of batteries, secondary batteries, battery electrodes, etc., can solve problems such as solid electrolyte/electrode interface compatibility issues, achieve shortened membrane material manufacturing time, excellent performance, and avoid running Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

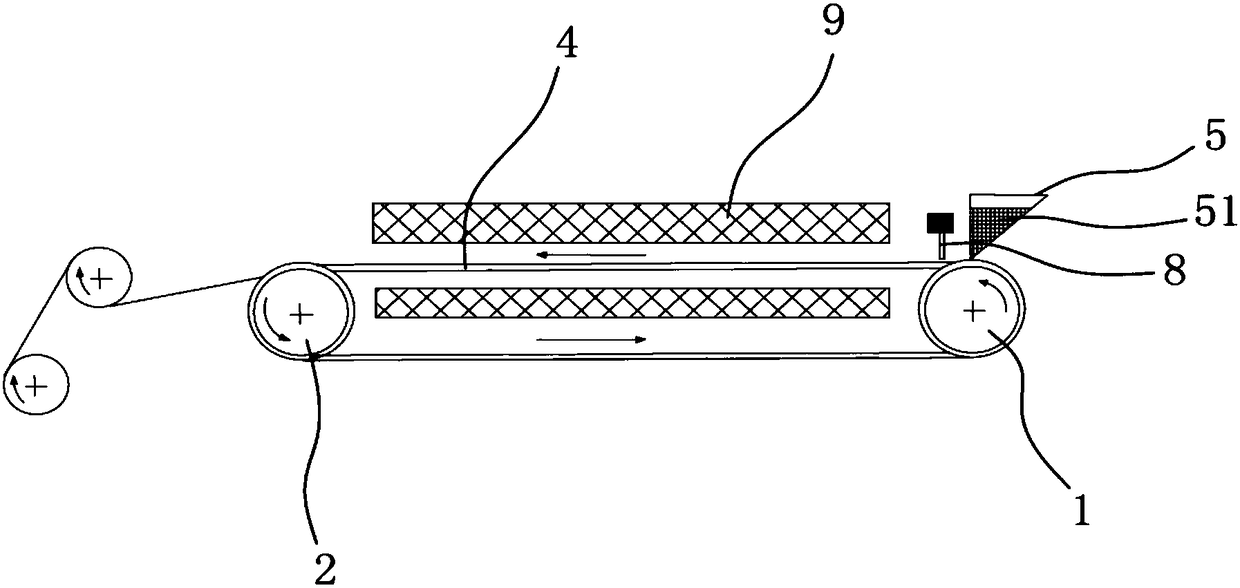

Method used

Image

Examples

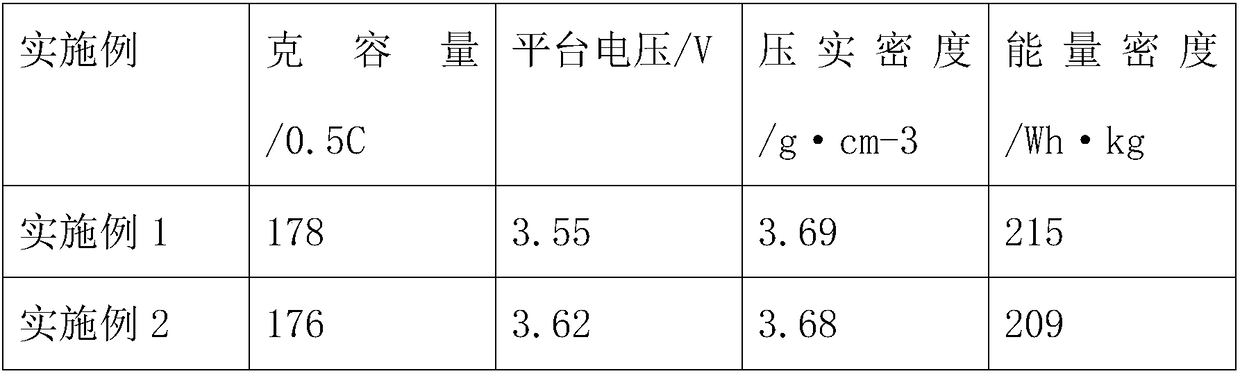

Embodiment 1

[0041] Prepare the positive active material: configure nickel sulfate, aluminum sulfate, cobalt sulfate mixed sulfate solution according to the molar ratio of 1:1:1; configure the mixed alkali solution of NaOH and ammonia water according to the molar ratio of 1:2; 2 / 3 co 2 / 3 mn 2 / 3 (OH) 2 Pour the precursor solution into the reaction kettle, run at a speed of 700r / min, and raise the temperature to 55°C, adjust the pH to 11.1, add the mixed sulfate solution and the mixed alkali solution dropwise, control the pH at 11.1, and let it sit and filter and dry; Mix the filtered and dried mixture with lithium carbonate, ball mill in a planetary ball mill at a speed of 180r / min for 15 hours, dry grind and roast at 750°C to obtain a positive electrode active material;

[0042] Positive electrode preparation: first dissolve 5 parts of PAA binder into 50 parts of PEG solvent, then add 85 parts of positive electrode active material and 2 parts of conductive agent and mix them in an agate ...

Embodiment 2

[0050] Prepare the positive active material: configure nickel sulfate, aluminum sulfate, cobalt sulfate mixed sulfate solution according to the molar ratio of 1:1:1; configure the mixed alkali solution of NaOH and ammonia water according to the molar ratio of 1:2; 2 / 3 co 2 / 3 mn 2 / 3 (OH) 2 Pour the precursor solution into the reaction kettle, run at a speed of 710r / min, and raise the temperature to 56°C, adjust the pH to 11.12, add the mixed sulfate solution and the mixed alkali solution dropwise, control the pH at 11.12, and let it sit and filter and dry; Mix the filtered and dried mixture with lithium carbonate, ball mill in a planetary ball mill at a speed of 185r / min for 16h, dry grind and roast at 760°C to obtain a positive active material;

[0051] Positive electrode preparation: first dissolve 6 parts of PAA binder into 52 parts of PEG solvent, then add 86 parts of positive electrode active material and 3 parts of conductive agent and mix them in an agate jar, place th...

Embodiment 3

[0059] Prepare the positive active material: configure nickel sulfate, aluminum sulfate, cobalt sulfate mixed sulfate solution according to the molar ratio of 1:1:1; configure the mixed alkali solution of NaOH and ammonia water according to the molar ratio of 1:2; 2 / 3 co 2 / 3 mn 2 / 3 (OH) 2 Pour the precursor solution into the reaction kettle, run at a speed of 725r / min, and raise the temperature to 57°C, adjust the pH to 11.15, add the mixed sulfate solution and the mixed alkali solution dropwise, control the pH at 11.15, and let it sit and filter and dry; Mix the filtered and dried mixture with lithium carbonate, ball mill in a planetary ball mill at a speed of 190r / min for 17h, dry grind and roast at 765°C to obtain a positive electrode active material;

[0060] Positive electrode preparation: first dissolve 8 parts of PAA binder into 55 parts of PEG solvent, then add 88 parts of positive electrode active material and 4 parts of conductive agent and mix them in an agate jar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com