Separated intelligent welding table

A separate, welding station technology, used in welding equipment, electric heating devices, auxiliary devices, etc., can solve problems such as short-circuit ignition, easy-to-touch wires, and excessive heating, avoiding electric shock, avoiding aging of heating cores, and improving safety factor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

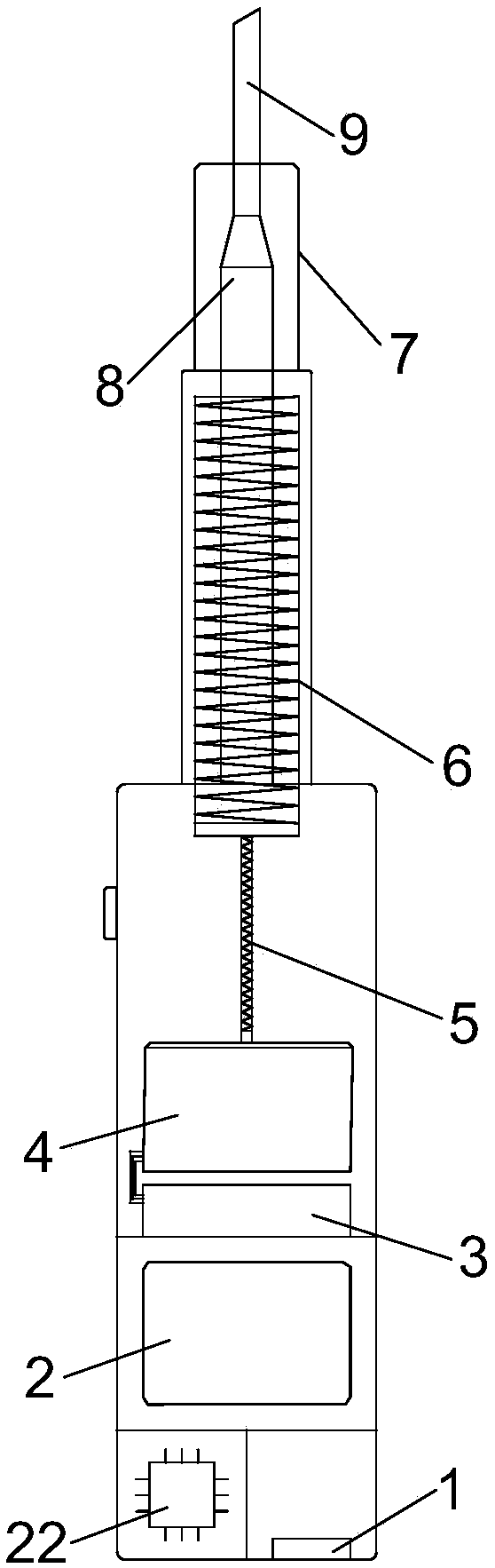

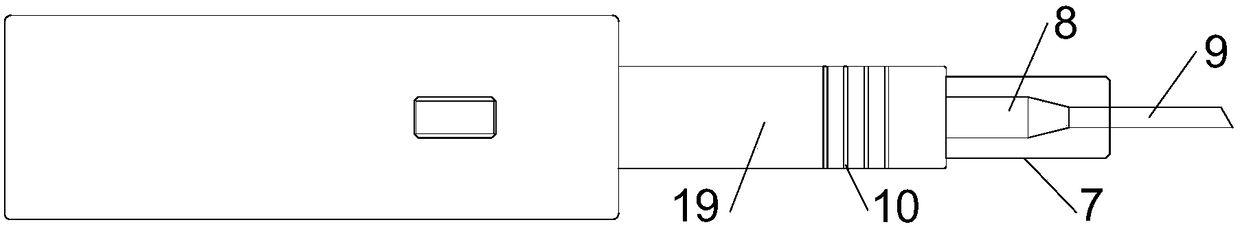

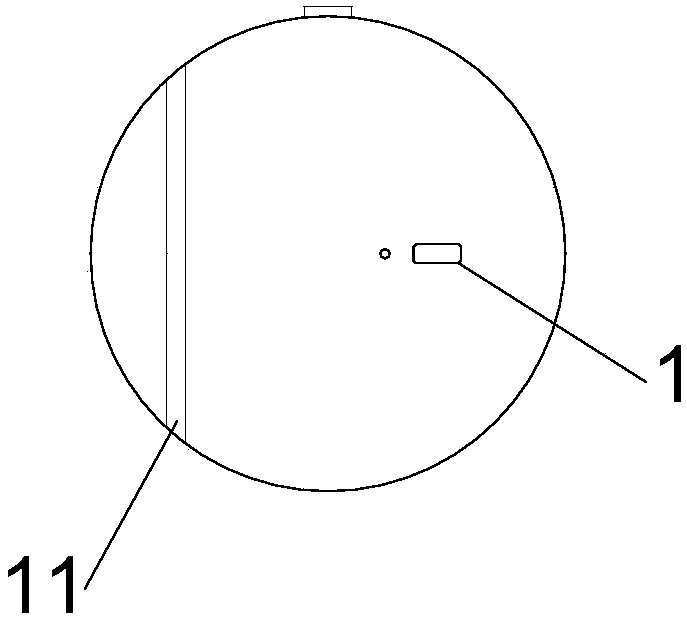

[0036] see Figure 1-9A separate intelligent soldering station, including a soldering station handle, a soldering station main body, an expansion component, a data interface 1, a rechargeable battery 2, a brushless motor 3, a brushless electronic speed controller 4, a screw drive rod 5, and a magnetic induction coil 6. Metal good conductor 7, heating core 8, soldering iron tip 9, expansion communication port 10, plastic strip 11, handle storage slot 12, sponge storage box 13, base control module 14, display 15, buttons 16, power supply module 17 , excitation coil 18, metal good conductor fixing seat 19, metal contact 20, expansion module 21 and control board 22, wherein, the control board 22 is arranged on the side of the bottom end of the handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com