Underground coal mine coal seam hydraulic fracturing-cutting coupling permeability-improving method

A hydraulic fracturing and hydraulic slotting technology, which is applied in earthwork drilling, wellbore/well components, mining fluids, etc., can solve problems such as small influence range of coal and rock mass permeability enhancement, coal seam crack damage, coal and gas outburst, etc. , to achieve the effects of improving gas drainage efficiency, eliminating stress concentration, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

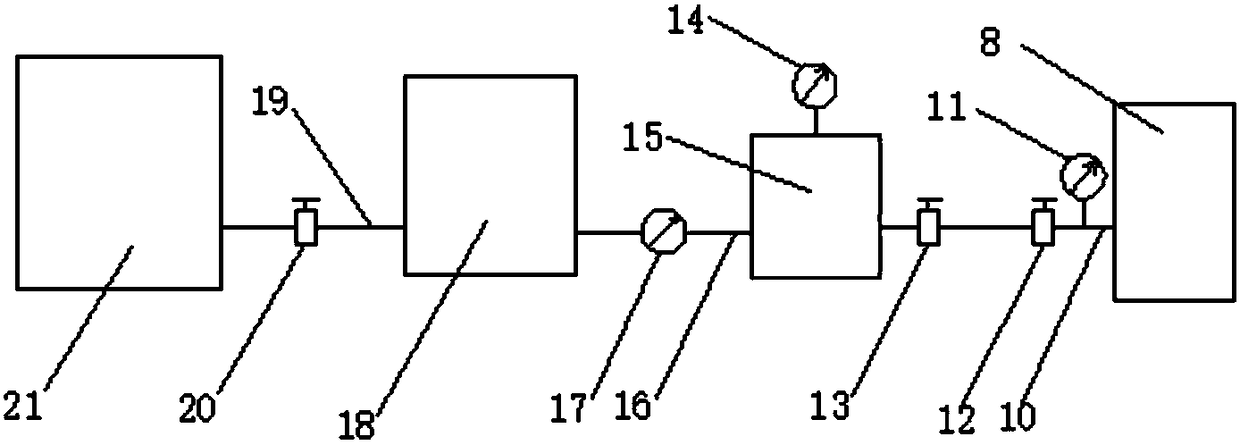

[0025] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

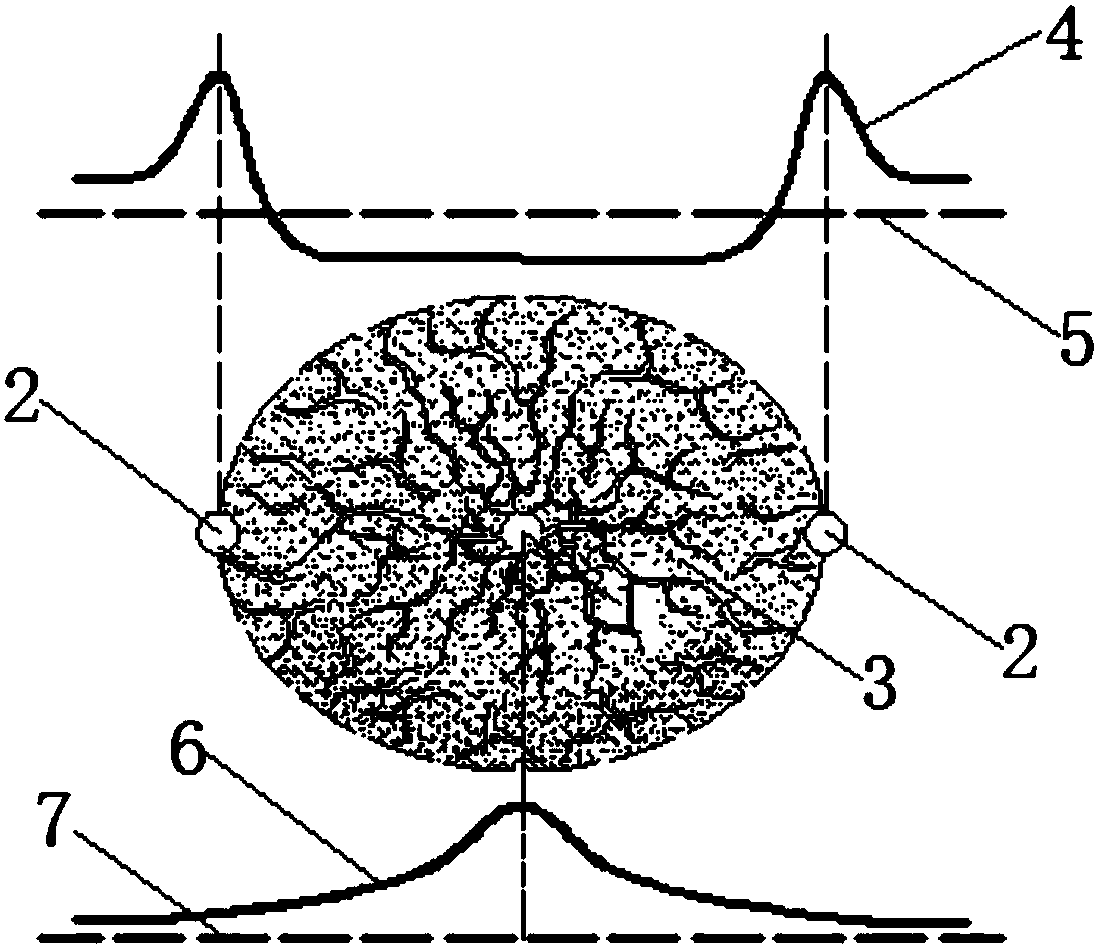

[0026] like Figure 1-4 Shown, the present invention comprises the steps:

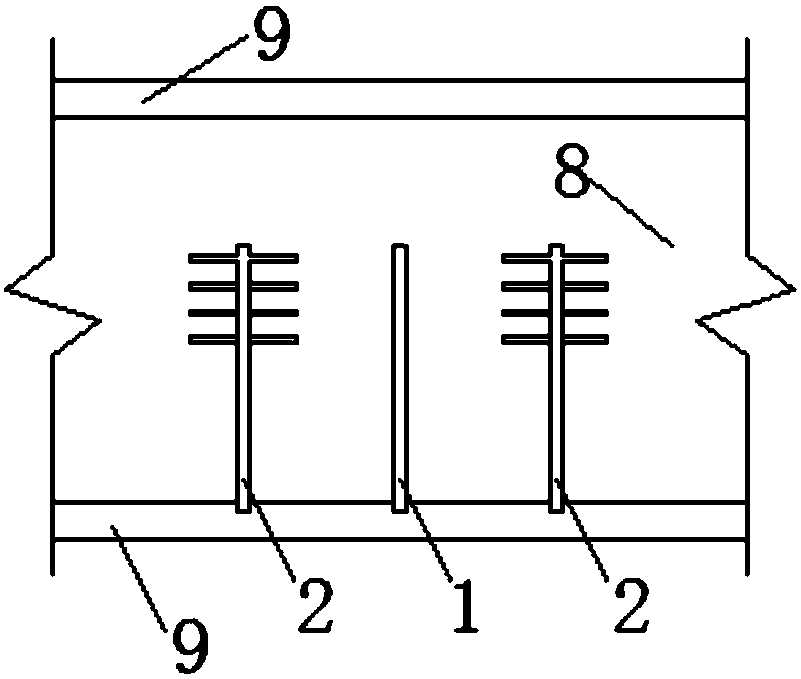

[0027] 1. Scientifically and reasonably determine the distance and position of the hydraulic fracturing borehole 1 and the hydraulic slotted borehole 2 according to on-site investigation and numerical simulation;

[0028] 2. Carry out hydraulic fracturing seepage enhancement treatment to the selected hydraulic fracturing borehole 1;

[0029] 3. Drill hydraulic slotted holes 2 in the stress concentration area caused by hydraulic fracturing, and perform hydraulic slotted pressure relief treatment.

[0030] In step 1, when arranging the hydraulic fracturing borehole 1 and hydraulic slotted borehole 2: firstly, according to the on-site measurement of coal-rock mass 8 joints and the development of holes and fissures, the coal-rock mass 8 strength and other mechanical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com