A real-time sampling device for coalbed methane production well packing methane detection and its application

A real-time sampling and coalbed methane technology, which is applied in the direction of measuring devices, sampling devices, and test sample preparation, can solve problems such as difficulty in ensuring convenience, speed, and real-time performance, difficulty in forming a methane capture space, and methane gas leakage. Achieve the effect of real-time, simple structure and continuous measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

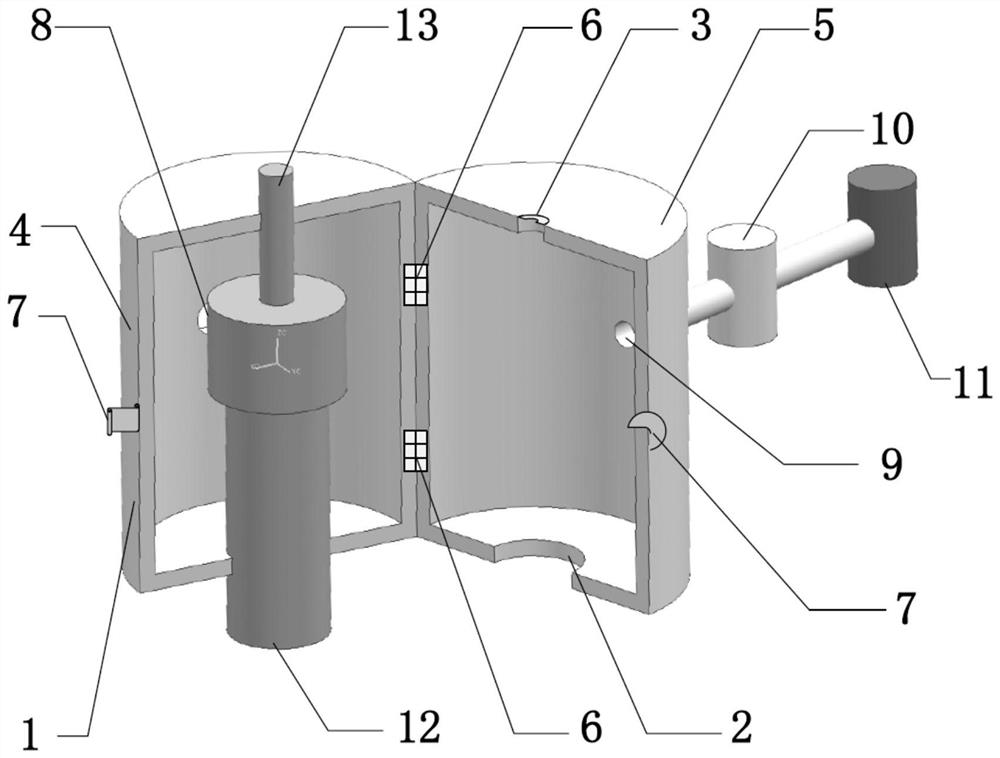

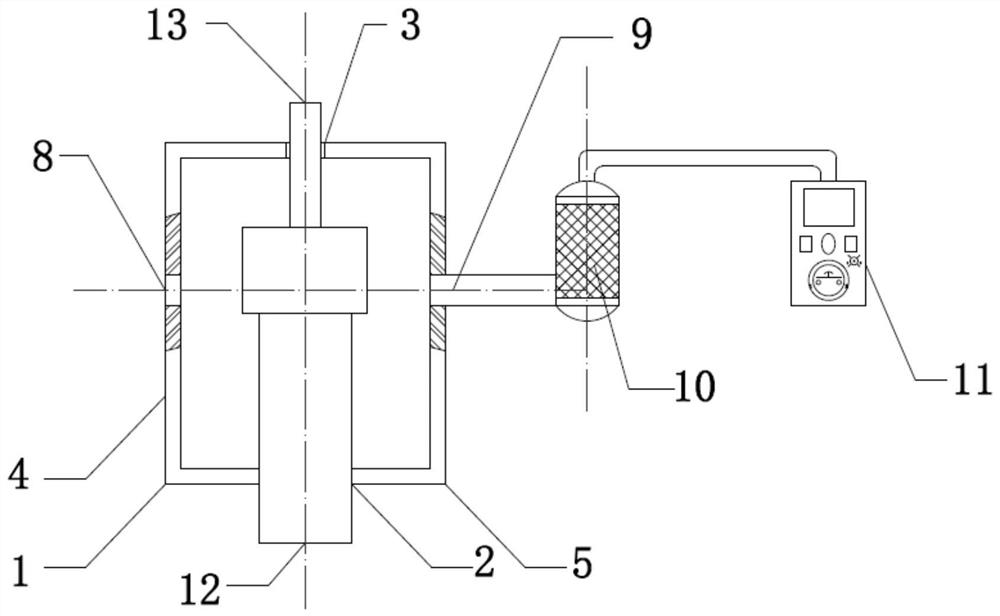

[0031] see figure 1 , figure 2 , which are respectively the perspective view of the methane detection real-time sampling device provided in this embodiment and the sampling system formed by it, and the on-site application schematic diagram of the methane detection real-time sampling device. The sampling device is a cylinder methane trap 1 formed by a closed combination of two half cylinders 4 and 5. At the closed combination, the two half cylinders 4 and 5 are hinged to connect 6 on one side, and the other side is connected by a hinge. The open lock 7 is connected to form a cylindrical methane trap 1 in a closed combination. The two half-cylinders 4, 5 have an upper bottom and a lower bottom independently, and the upper bottom or lower bottom of the two half-cylinders 4, 5 Grooves 3 and 2 are arranged on the inner edge of the bottom surface. When the two half cylinders 4 and 5 are airtightly combined, the grooves 3 on the inner edge of the upper bottom surface of the two hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com