Metal wire meter resistance continuous precision testing device and method

A test device, meter resistance technology, applied in the direction of measuring device, measuring resistance/reactance/impedance, measuring electrical variables, etc., can solve the problems of wire surface indentation, large error, complicated process, etc., and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

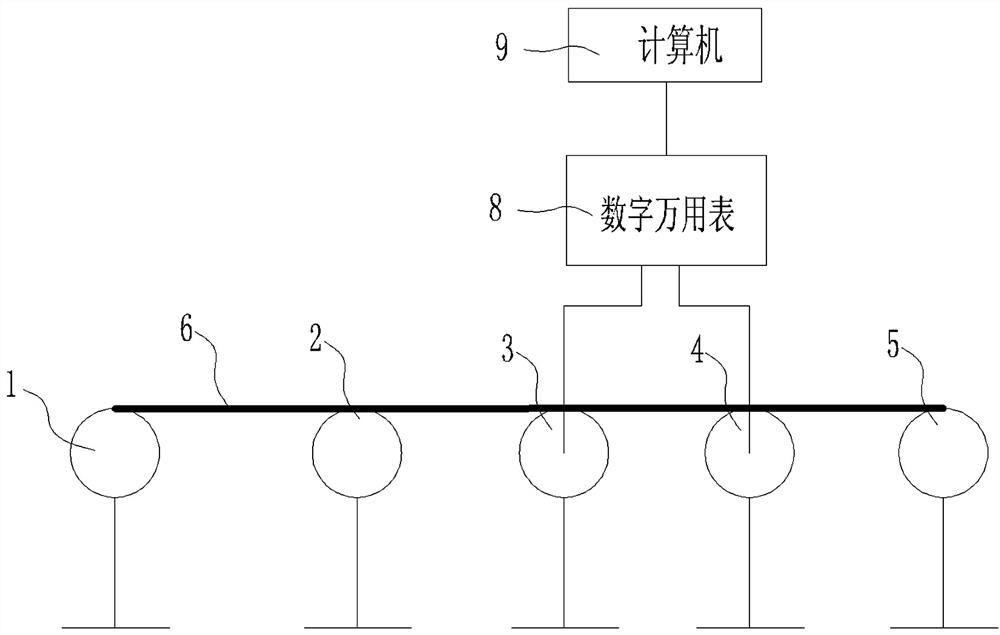

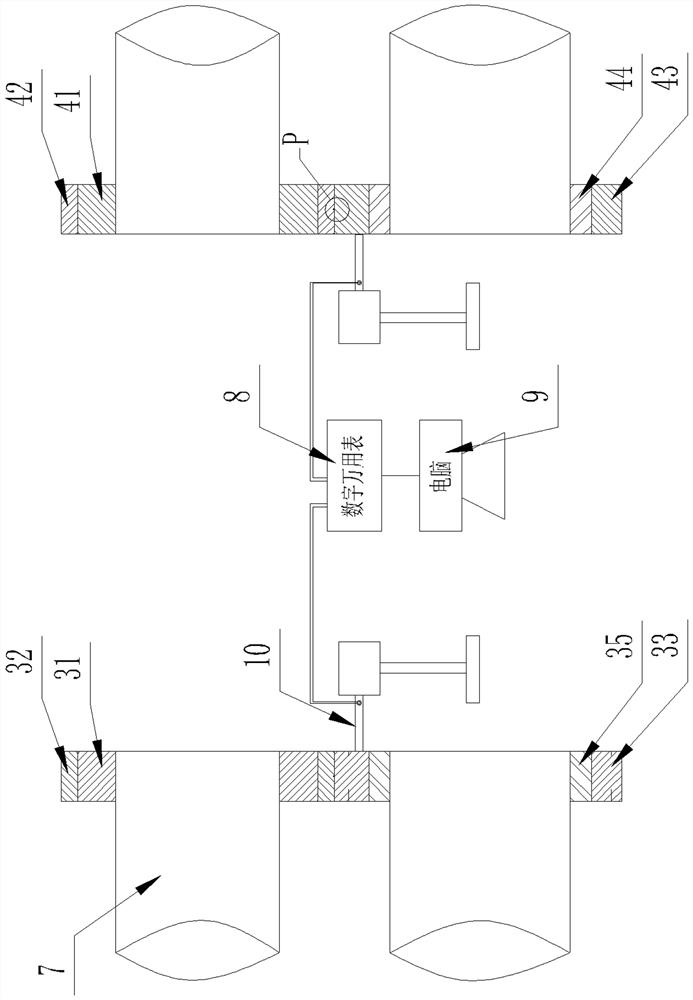

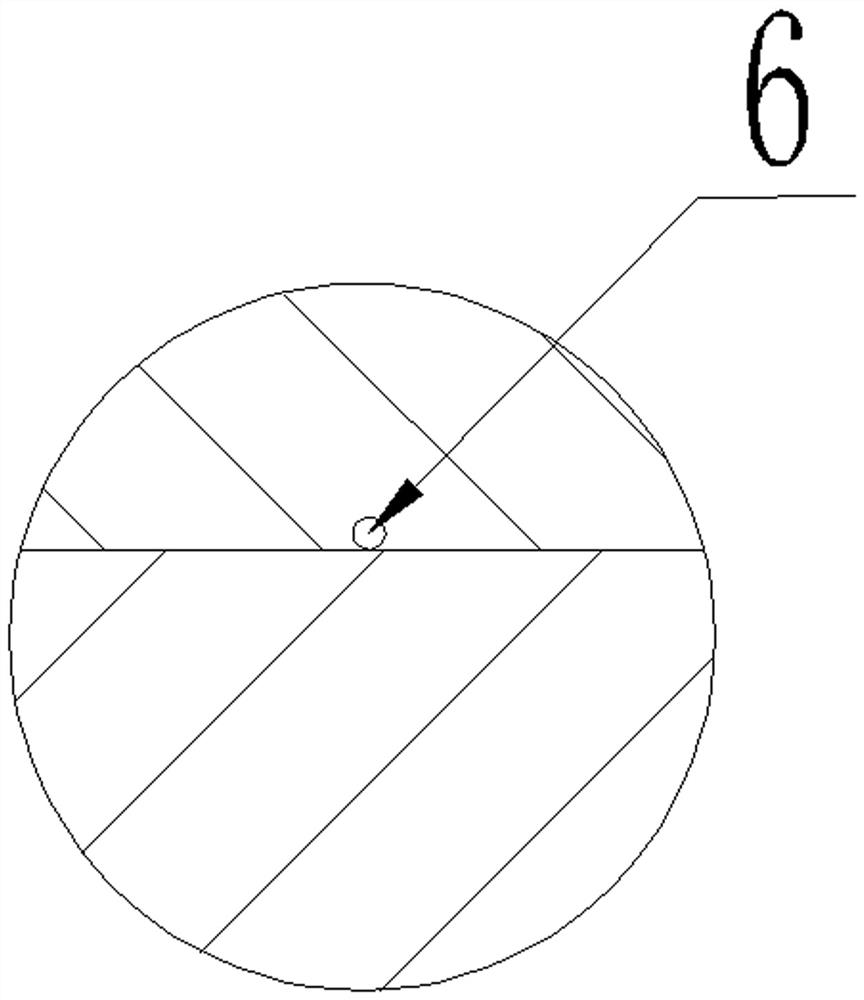

[0037] See Figure 1 to Figure 6 , A metal wire meter resistance continuous precision test device, comprising a wire pay-off device 1 and a wire take-up device 5. A resistance collection device is arranged between the wire take-up device 1 and the wire take-up device 5, and the resistance collection device includes A first upper and lower roller device 3 and a second upper and lower roller device 4 are arranged at intervals in the length direction of the wire to be measured. The upper roller and the lower roller of the first upper and lower roller devices 3 and the second upper and lower roller devices 4 respectively correspond to the corresponding rotating shafts 7 Circumferentially fixedly connected and supported on the corresponding rotating shaft 7, the rotating shaft 7 is connected with the driving device, so that the driving device drives the upper roller and the lower roller to rotate; the lower roller of the first upper and lower roller device 3 includes a first lower ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com