Method for predicting and analyzing cutting deformation of thin-walled structural parts

A thin-walled structural part, cutting technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as low computational efficiency, unrealistic, and large computational resources consumption, and achieve accurate finite element analysis results. , the simulation results are accurate, the analysis results are efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

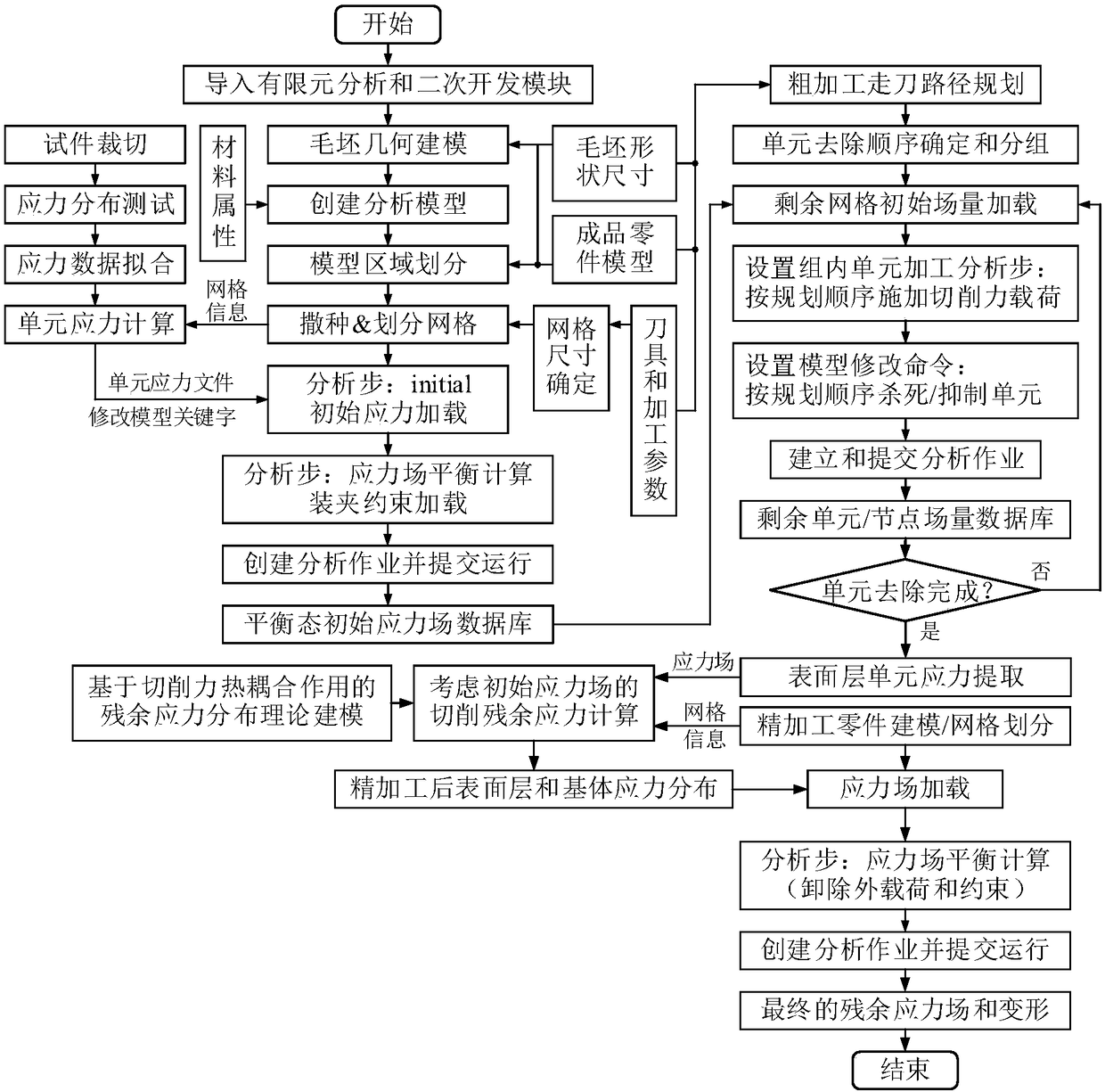

[0033] The mechanism of the overall machining deformation of thin-walled parts lies in the workpiece blank containing initial residual stress. The stress field evolves gradually, and after the processing is completed and the clamping is removed, the internal stress field further evolves and causes the parts to deform, and finally reaches the state of internal stress self-balance. In order to predict and analyze the processing deformation of thin-walled structural parts, it is necessary to track the evolution process of the internal stress field under external influences, and to process the data through efficient computing means to obtain the final processing deformation.

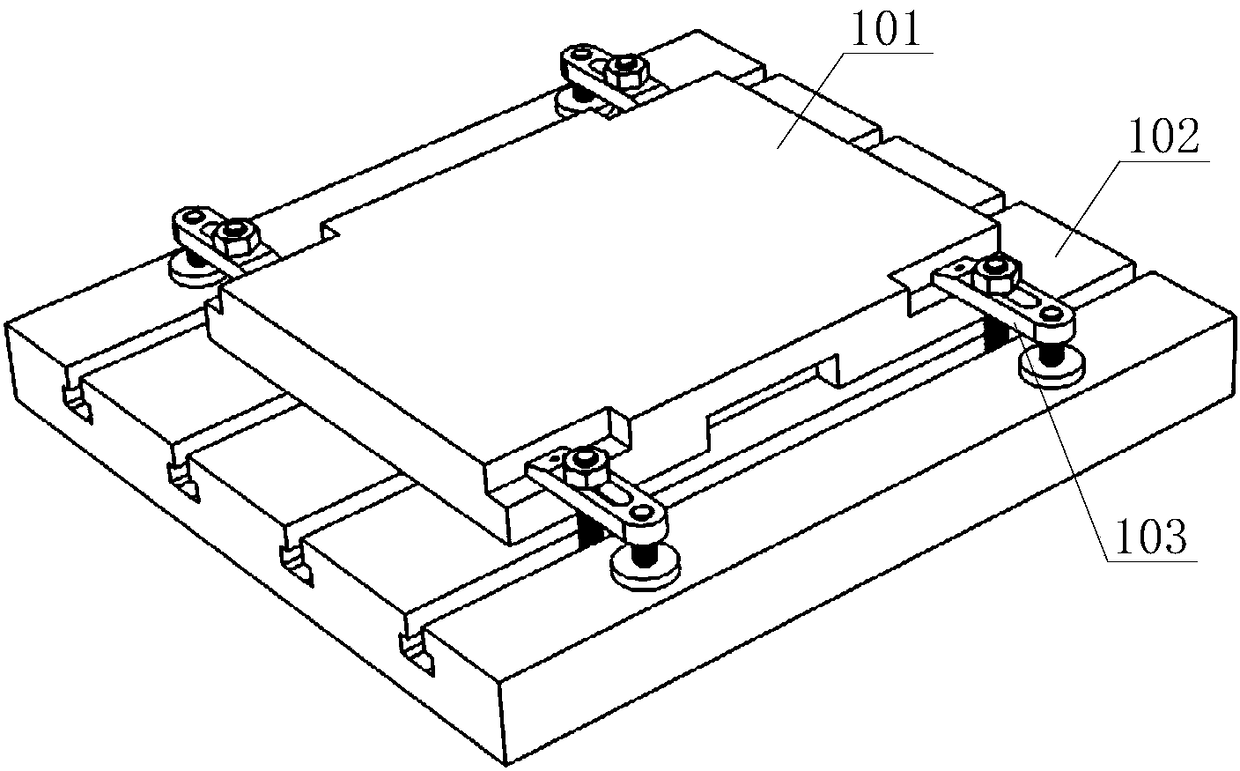

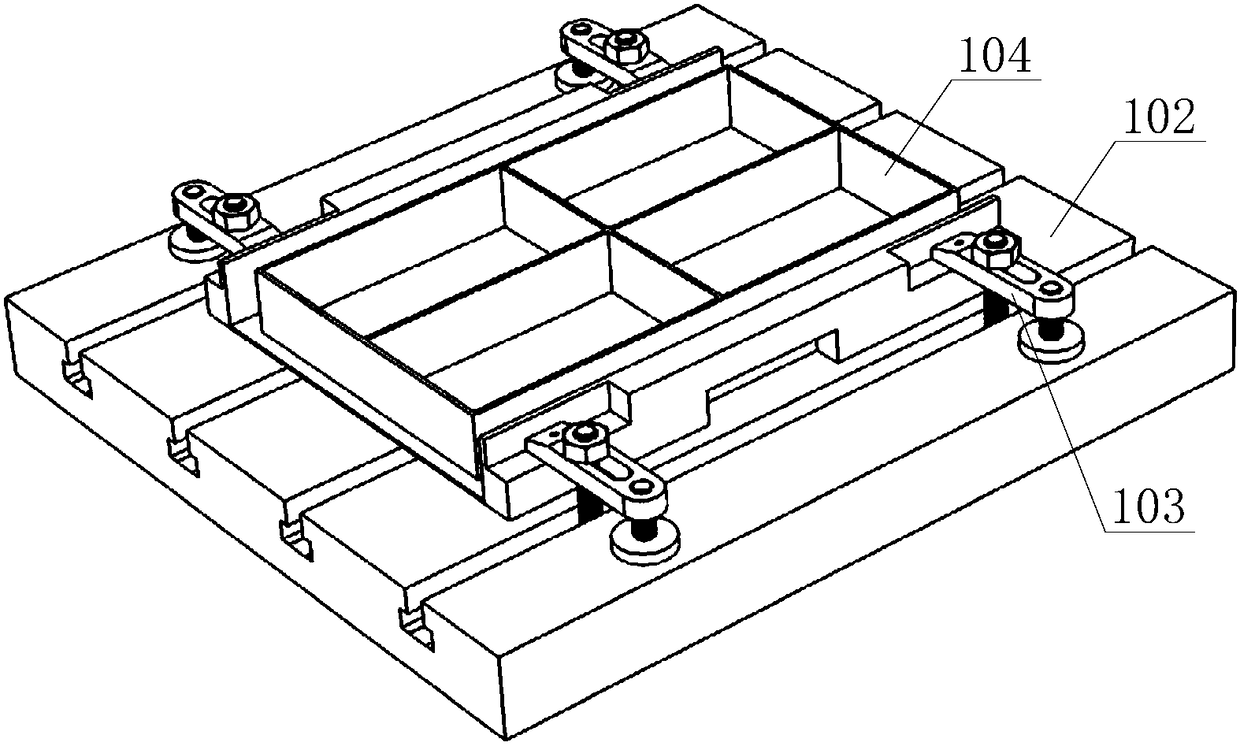

[0034] The invention provides a method for predicting and analyzing the deformation of thin-walled structural parts during cutting. Based on the combination of finite element simulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com