High-concentration-ratio high-temperature-resistant light-weight organic waste gas concentration device and method

A technology of organic waste gas and high temperature resistance, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems that are not conducive to improving the efficiency of adsorption and purification, cannot cool the adsorption materials, increase the number of desorption treatment objects, etc., and achieve improved modification The effect of flexibility, prolonging the effective life, and broadening the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0055] An example of adsorption and desorption purification of organic waste gas in a door industry.

[0056] The waste gas of this factory mainly comes from the painting waste gas generated in the painting process during the production process of anti-theft doors and fire doors. The components of the painting waste gas are mainly paint mist and organic waste gas. The organic waste gas mainly includes non-methane total hydrocarbons, alcohols, and esters. Wait. The maximum total air volume of the workshop is 189600m 3 / h, the design total air volume is 200000m 3 / h meter, the average exhaust gas concentration is 200-250mg / m 3 ,

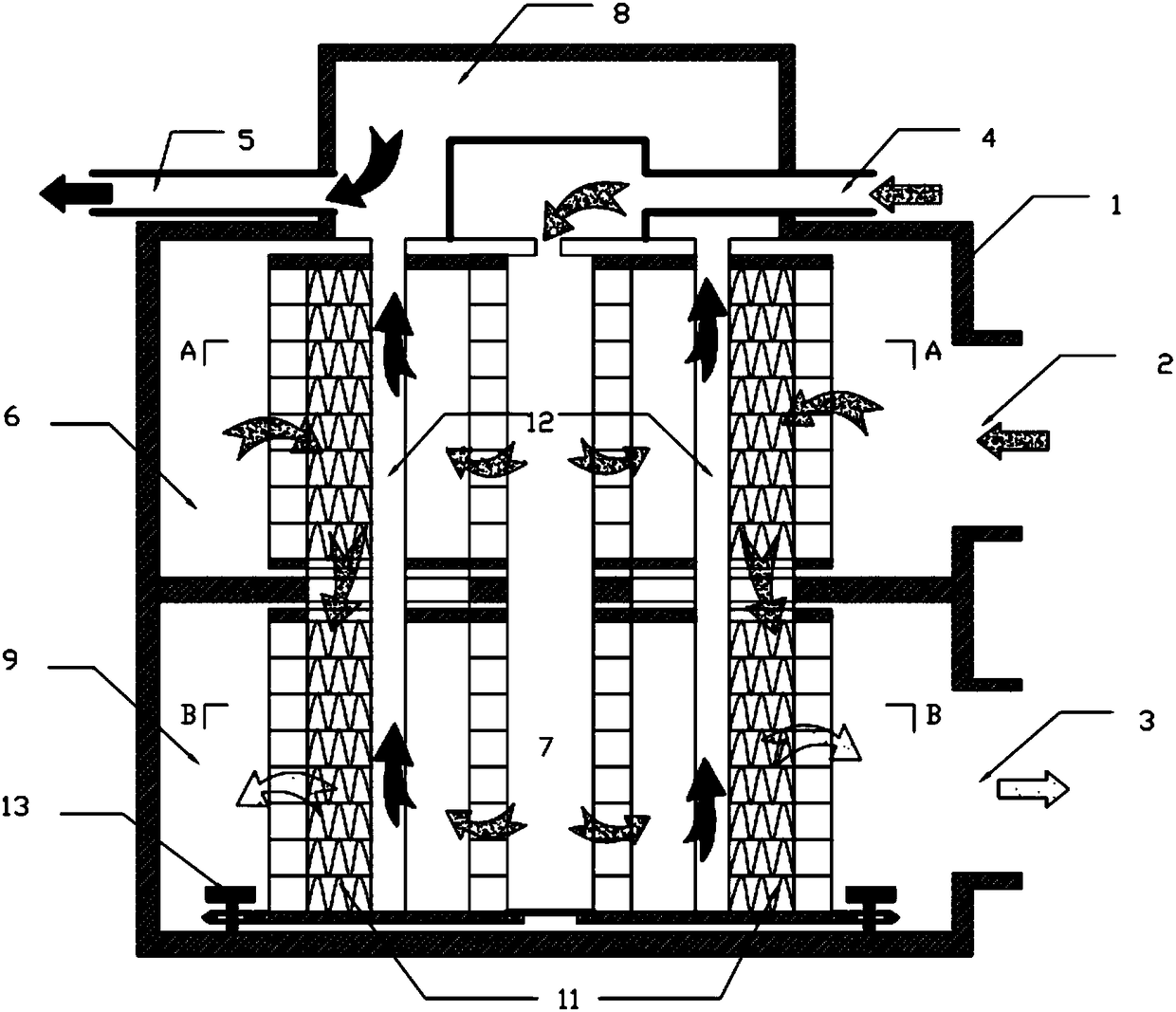

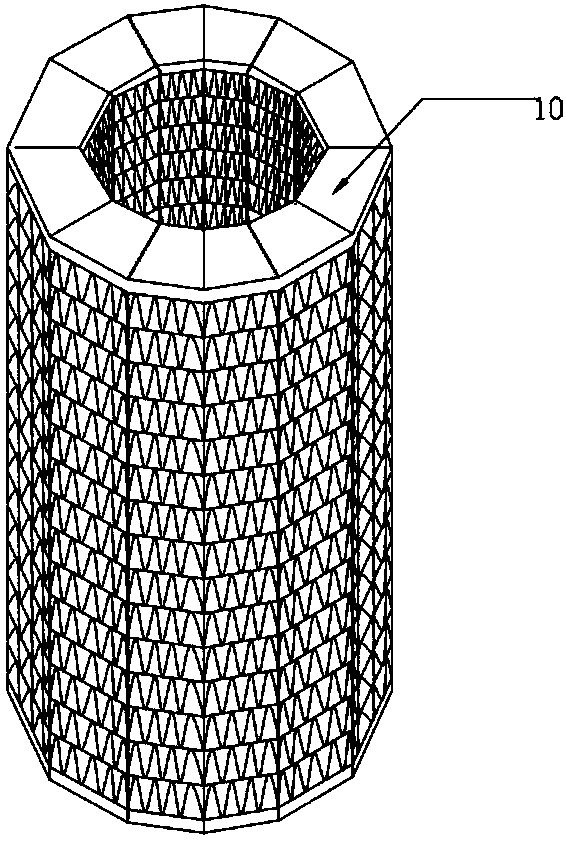

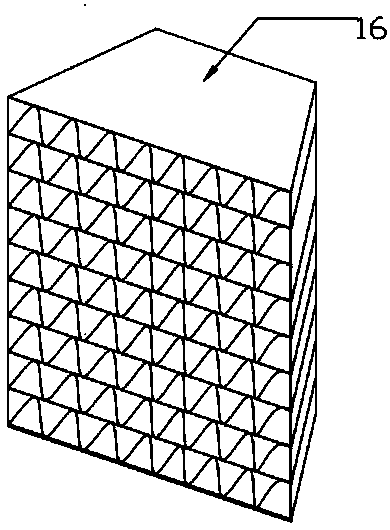

[0057] The high-concentration ratio high-temperature-resistant light-duty organic waste gas concentration device provided by the present invention can be found in the attached Figure 1-5 , its equipment and technological process are as follows:

[0058] The device uses 4 sets of cores to purify the waste gas of the plant at the same time. The des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com