Automatic conveying bulletproof helmet five-station six-hole drilling machine

A bulletproof helmet and automatic transmission technology, which is applied in metal processing and other directions, can solve the problems of large drilling position accuracy error, time-consuming and labor-intensive, and affecting work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below through specific examples and in conjunction with the accompanying drawings.

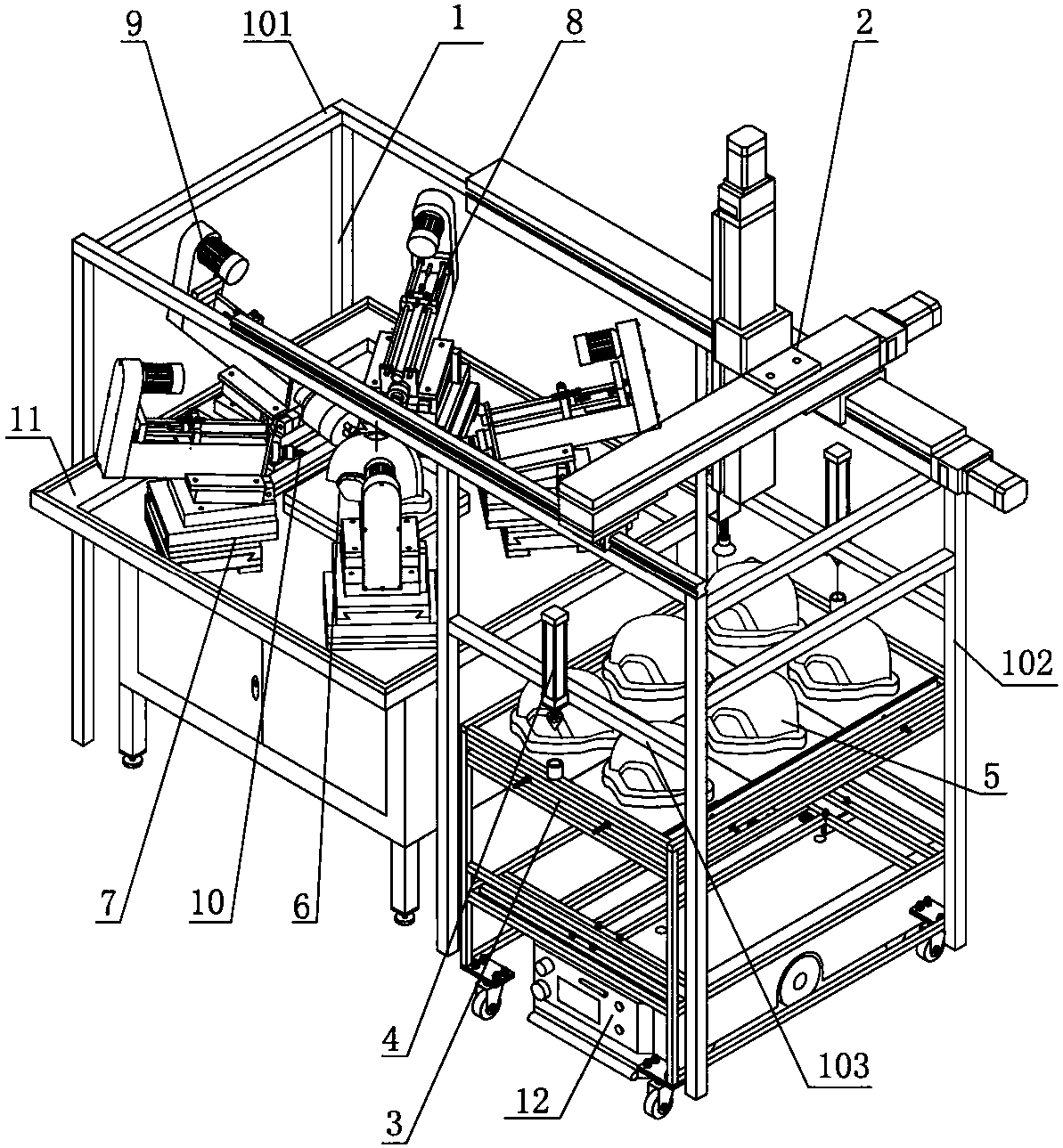

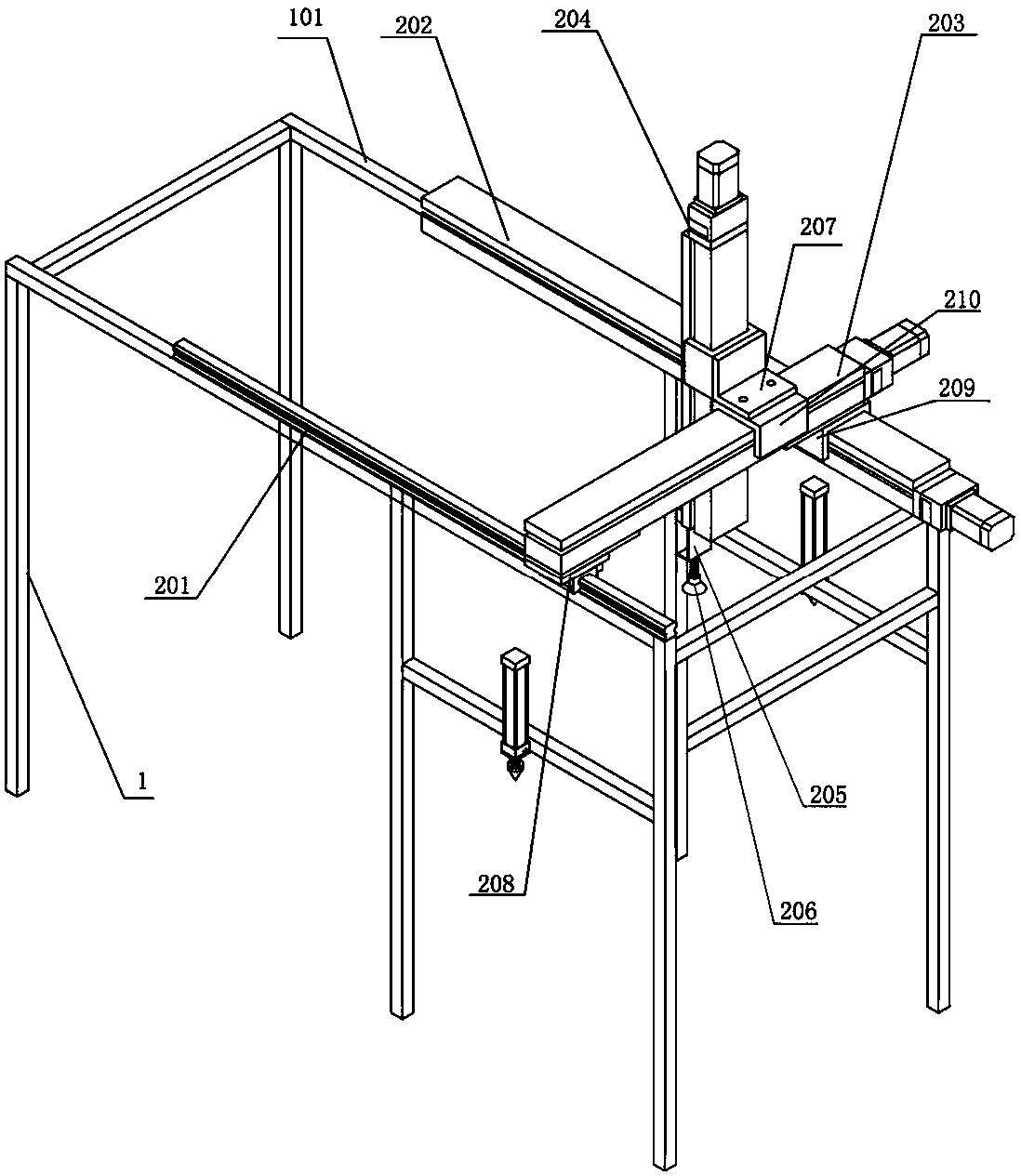

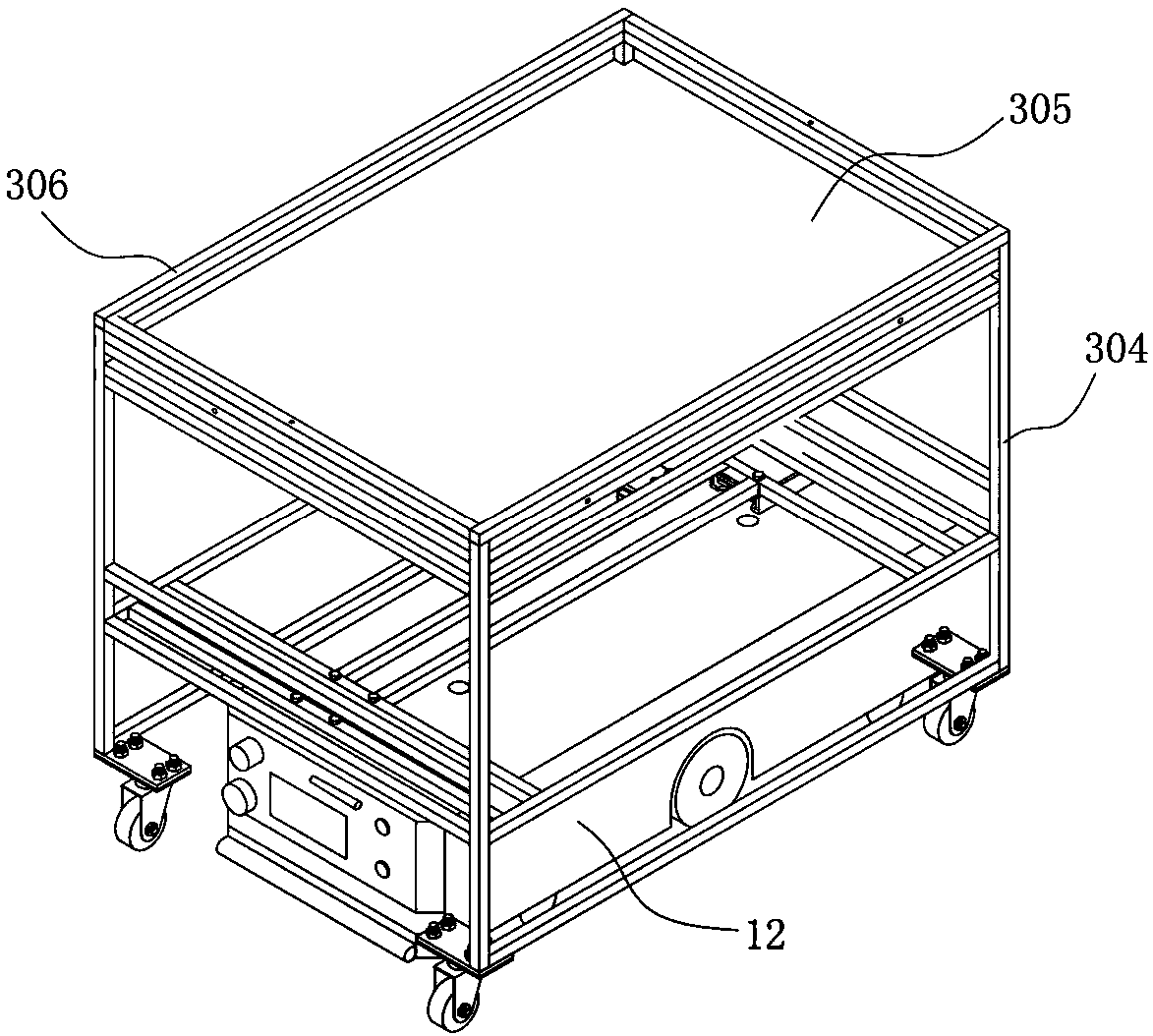

[0042] as attached figure 1 As shown, the present invention includes frame, bulletproof helmet grasping and putting back device 2, bulletproof helmet delivery vehicle 3, delivery vehicle positioning device 4, delivery vehicle bulletproof helmet positioning device 5, bulletproof helmet drilling positioning mold and ejector device 6 , a multifunctional adjustment base 7, a single-bit gas-electric integrated drilling device 8, a double-drill gas-electric integrated drilling device 9 and a drill bit 10; On the end of the electric integrated drilling device 9; the frame includes a frame body 1, and the frame body 1 includes an upper frame 101 arranged on the top and a side frame 102 arranged on the side, and the middle frame is arranged in the side frame 102 103; a drilling workbench 11 is set below the upper frame 101; the bulletpro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com