Long-acting inflaming retarding composition for wooden cultural relic heritage building and inflaming retarding treatment method thereof

A flame retardant composition and wood technology, applied in wood treatment, wood treatment details, wood impregnation, etc., can solve the problems of not being used, weak wood permeability, etc., and achieve good flame retardant effect and excellent permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

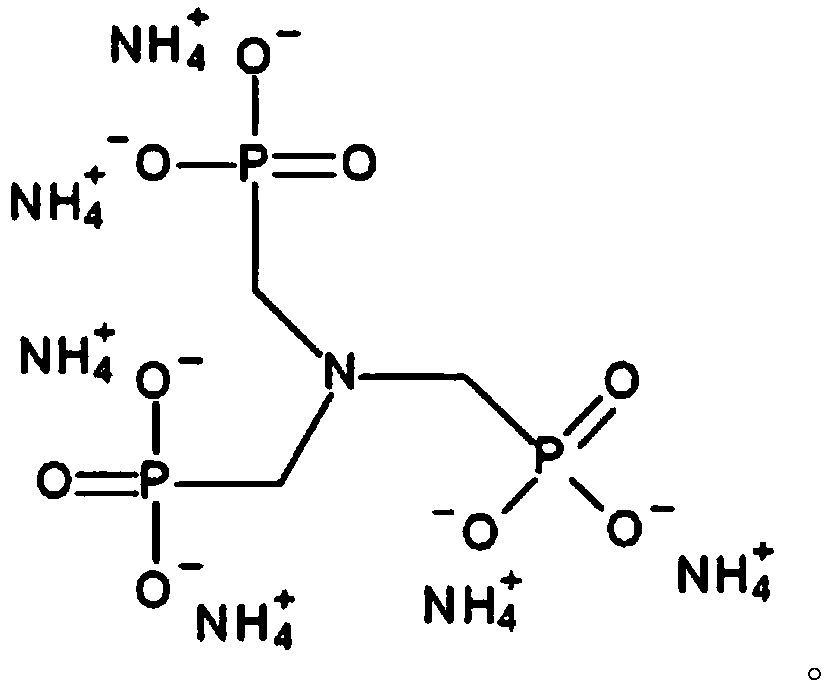

[0089]Example 1: Manufacture of long-acting flame retardant composition for wooden cultural relics and ancient buildings of the present invention and evaluation of flame retardant effect

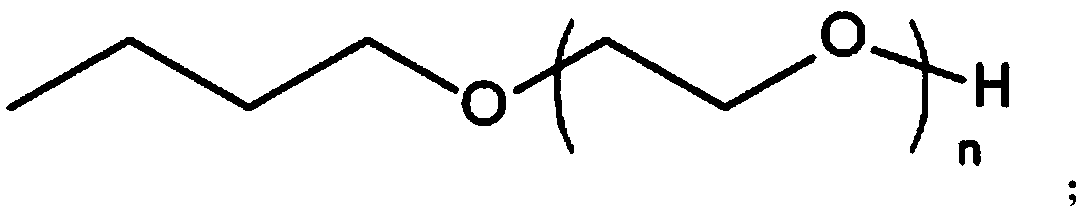

[0090] 65 parts by weight of water and 25 parts by weight of ammonium nitrilo(methylene)triphosphonate (AMGUARD DR) represented by Chemical Formula 1 were added to a flask equipped with a stirrer, and stirred and mixed for 2 hours. Add 5 parts by weight of 3-aminopropyl triethoxysilane (3-aminopropyl triethoxysilane) to the mixed solution produced, and after stirring for 1 hour and 45 minutes, add diethylene glycol monobutyl ether and butyl cellosolve as penetrating agent 5 parts by weight of the 4:6 (weight ratio) mixture was stirred for 2 hours and 30 minutes to manufacture the fire-retardant composition for wooden cultural relics and ancient buildings.

[0091] The long-acting flame retardant composition for wooden cultural relics and ancient buildings produced was evaluated for whether i...

Embodiment 2

[0100] Example 2: Manufacture of long-acting flame retardant composition for wooden cultural relics and ancient buildings of the present invention and evaluation of flame retardant effect

[0101] As a penetrating agent, except that instead of 5 parts by weight of a 4:6 (weight ratio) mixture of diethylene glycol monobutyl ether and butyl cellosolve, 5 parts by weight of diethylene glycol monobutyl ether is used, the same as in Example 1 The method for manufacturing the long-acting flame retardant composition for wooden cultural relics and ancient buildings.

[0102] For the long-acting flame retardant composition for the described wooden cultural relics and ancient buildings manufactured, evaluate whether it contains harmful substances and basic physical properties, the results are shown in Table 4; and evaluate the weather resistance, the results are shown in Table 5; evaluate the flame retardancy , and the results are shown in Table 6.

[0103] Table 4

[0104]

[0105...

Embodiment 3

[0111] Example 3: Manufacture of long-acting flame retardant composition for wooden cultural relics and ancient buildings of the present invention and evaluation of flame retardant effect

[0112] As a penetrating agent, except that instead of 5 parts by weight of a 4:6 (weight ratio) mixture of diethylene glycol monobutyl ether and butyl cellosolve, 5 parts by weight of butyl cellosolve is used, the same method as in Example 1 is used to manufacture wood A long-acting flame retardant composition for cultural relics and ancient buildings.

[0113] For the manufactured long-acting flame retardant composition for wooden cultural relics and ancient buildings, evaluate whether it contains harmful substances and basic physical properties, the results are shown in Table 7; and evaluate the weather resistance, the results are shown in Table 8; evaluate the flame retardancy , and the results are shown in Table 9.

[0114] Table 7

[0115]

[0116] Table 8

[0117]

[0118] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com