Manufacturing method for spot irradiating type floating floor vibration isolation and sound insulation blocks

A technology for floating floor slabs and a manufacturing method, which is applied in the direction of protective buildings/shelters, sound insulation, construction, etc., can solve the problems of short service life, floating collapse, low price of rubber blocks, etc., and achieves long service life without difficulty The effect of cracking, good moisture resistance and fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] After recycling waste tires, crush them into rubber particles with a diameter of about 10mm. After the crushing is completed, select cork particles with a diameter of about 10mm, and mix the cork particles, rubber particles, and water-based glue in a ratio of 2:2:1, and the mixing is completed. Then it is placed in a container and heated so that the temperature of the mixture is maintained at 150°C. Stir while heating. After stirring for 70min, stop heating and apply a pressure of 9000Pa to the mixture. When the mixture is cooled to 25°C (at this time The mixture has cooled into a block), the pressurization is stopped, and the block mixture is cut into cubes of 50mm size. The detection of low-frequency noise attenuation is carried out in accordance with GBJ75-1984 and GB / T19889.6-2005.

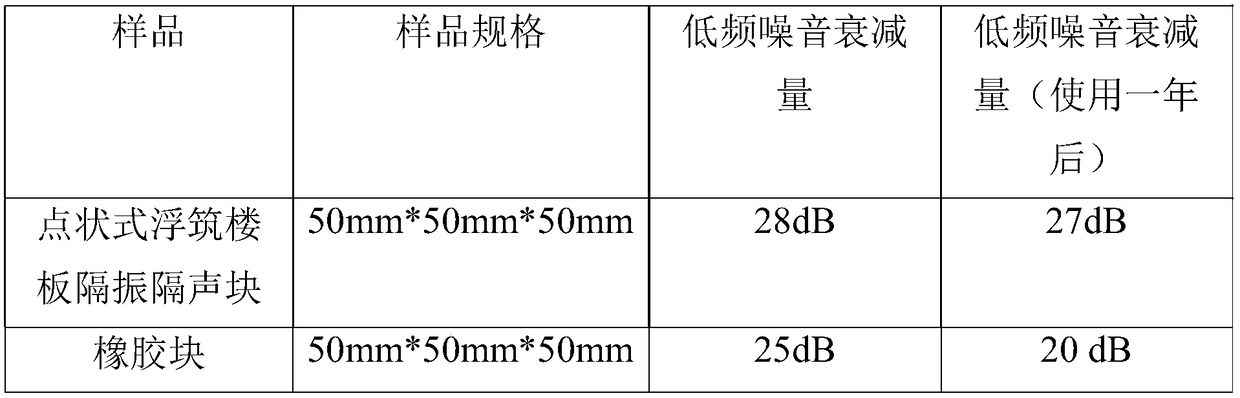

[0024] Table 1 is the comparison index of each parameter detection of embodiment 1

[0025]

Embodiment 2

[0027] After the waste cable sheath is recovered, it is crushed into rubber particles with a diameter of about 5mm. After the crushing is completed, cork particles with a diameter of about 10mm are selected, and the cork particles, rubber particles, and water-based glue are mixed in a ratio of 3:2:2. After completion, it is placed in a container and heated so that the temperature of the mixture is maintained at 140 ° C. Stir while heating. After stirring for 90 minutes, stop heating and apply a pressure of 7000 Pa to the mixture. When the mixture is cooled to 25 ° C (this When the mixture has cooled into a block), the pressurization is stopped, and the block mixture is cut into cubes of 50mm size. The detection of low-frequency noise attenuation is carried out in accordance with GBJ75-1984 and GB / T19889.6-2005.

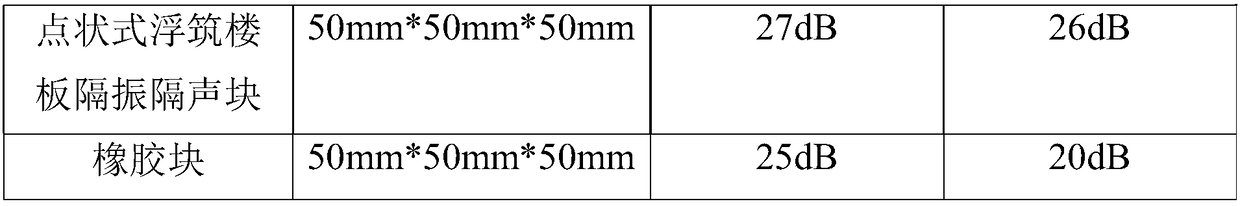

[0028] Table 2 is each parameter detection contrast index of embodiment 2

[0029]

[0030]

Embodiment 3

[0032] After recycling the rubber soles of waste rubber shoes, crush them into rubber particles with a diameter of about 8mm. After the crushing is completed, select cork particles with a diameter of about 8mm, and mix the cork particles, rubber particles, and water-based glue in a ratio of 4:2:3. After the mixing is completed, place it in a container and heat it so that the temperature of the mixture is maintained at 170 ° C. Stir while heating. After stirring for 120 minutes, stop heating and apply a pressure of 5000 Pa to the mixture. When the mixture is cooled to 25 ° C (at this moment, the mixture has cooled to block), the pressurization is stopped, and the block mixture is cut into cube blocks of 50mm size. The detection of low-frequency noise attenuation is carried out in accordance with GBJ75-1984 and GB / T19889.6-2005.

[0033] Table 3 is each parameter detection comparison index of embodiment 3

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com