Preparation method for ketal

A ketal, cedar alkanediol technology, applied in chemical recycling, organic chemistry, etc., can solve problems such as poor selectivity, low conversion rate, and three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

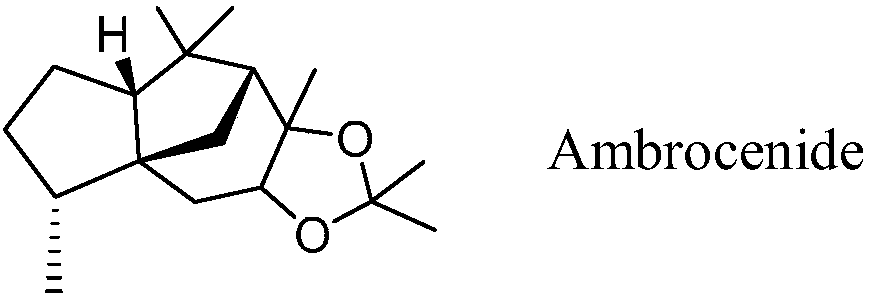

Image

Examples

Embodiment 1

[0037] Mix 10g (42 mmol) of cedaranediol, 0.41 g (4.2 mmol) of sulfamic acid, 100 ml of ethyl acetate, and 9.5 g (91 mmol) of dimethoxypropane, and stir the reaction solution at 20-25°C Reacted for 24 hours, the reaction solution was washed with water twice, each time with 50 milliliters of water, washed to neutrality, then the organic phase was concentrated to dryness, and then recrystallized with ethanol to obtain 11.1 g of white crystals, the yield was 95%, and the GC content = 99.0%, GC-MS: m / z=238[M]+. The aqueous phase containing the catalyst was separated with toluene to obtain 0.5 g of sulfamic acid, which can be directly used repeatedly.

Embodiment 2

[0039] Mix 10g (42 mmol) of cedaranediol, 0.41 g (4.2 mmol) of sulfamic acid, 100 ml of ethyl acetate, and 9.5 g (91 mmol) of dimethoxypropane, and the reaction solution is heated and refluxed for 76 to 78 ℃ for stirring and reacting for 3 hours, the reaction solution was washed twice with 50 milliliters of water each time until neutral, and then the organic phase was concentrated to dryness to obtain 11.1 g of white crystals with a yield of 95%, GC content=99.0%, GC - MS: m / z=238[M]+. The aqueous phase containing the catalyst was dehydrated with benzene to obtain 0.5 g of sulfamic acid, which can be directly used repeatedly.

Embodiment 3

[0041] With 10g (42 millimoles) cedaranediol, 0.41 grams (4.2 millimoles) sulfamic acid (the catalyst that embodiment 1 reclaims and obtains), ethyl acetate 100 milliliters, 9.5g (91 millimoles) dimethoxypropane Mix, react the reaction solution at 20-25°C for 24 hours with stirring, wash the reaction solution with water twice, each time with 50 ml of water until neutral, then concentrate the organic phase to dryness, and then recrystallize with ethanol to obtain 11.1 g of white crystals , yield 95%, GC content=99.0%, GC-MS: m / z=238[M]+. The aqueous phase containing the catalyst was separated with toluene to obtain 0.5 g of sulfamic acid, which can be directly used repeatedly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com