Fabricated heat-preservation and sound-insulation wallboard

A thermal insulation and sound insulation, prefabricated technology, applied in building components, buildings, building structures, etc., can solve problems such as poor thermal insulation, single function, quality problems, etc., and achieve the effect of wide application, enhanced bearing capacity, and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

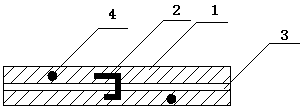

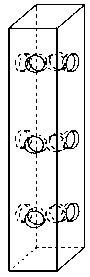

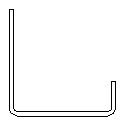

[0030] As shown in FIG. 1, a prefabricated thermal insulation and sound insulation wall panel includes a board 1, a steel frame 2, a reinforced threading pipe 3, and a water pipe 4. The board 1 is made of foamed cement board, and the board 1 penetrates horizontally through it. Two parallel reinforced threading pipes, the reinforced threading pipes are square pipes with inwardly protruding punching holes uniformly made on all four sides, such as figure 2 shown. A steel frame runs vertically through the middle of plate 1, and the cross-section of the steel frame is an uppercase L shape, such as image 3 As shown, the schematic diagram of the L-shaped steel frame unfolding is shown in Fig. Figure 4 As shown, the two sides of the frame are separated by holes, and the holes on both sides are staggered for connecting the adjustment piece and the mounting plate. The holes on one side are vertical strip holes and horizontal strip holes alternately, and the holes on the other side a...

Embodiment 2

[0034] It is basically the same as Example 1, except that the board is made of straw, two parallel steel frames are vertically arranged in the board, and a water pipe is vertically arranged between the two parallel steel frames. The boards with water pipes can be directly used as wall panels, which can be directly used to assemble simple houses, and there is no need to construct a water pipe groove. like Figure 7 As shown, it can be used for the renovation of village houses in rural areas, tourist attraction houses, sea view houses, rural retirement houses, desert environmental protection planting houses, guard houses, etc.

Embodiment 3

[0036] Basically the same as Example 2, the difference is that the board is a composite board, and a carbon fiber heating cable 5 is arranged on one side of the board, which can be directly used as a wall board to assemble a simple room, and there is no need to install heating equipment such as heating and geothermal when building a house. Wall panels with water pipes and carbon fiber heating cables can be used to build plant houses, or residential, simple houses, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com