Resonance type magnetic sensor sensitive unit and digital frequency output magnetic sensor

A technology of magnetic sensor and sensitive unit, which is applied in the direction of magnetic field measurement and magnetic field size/direction by using electromagnetic devices, which can solve the problems of reducing the transmission efficiency of magnetostrictive stress, and achieve the effects of low cost, high sensitivity and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

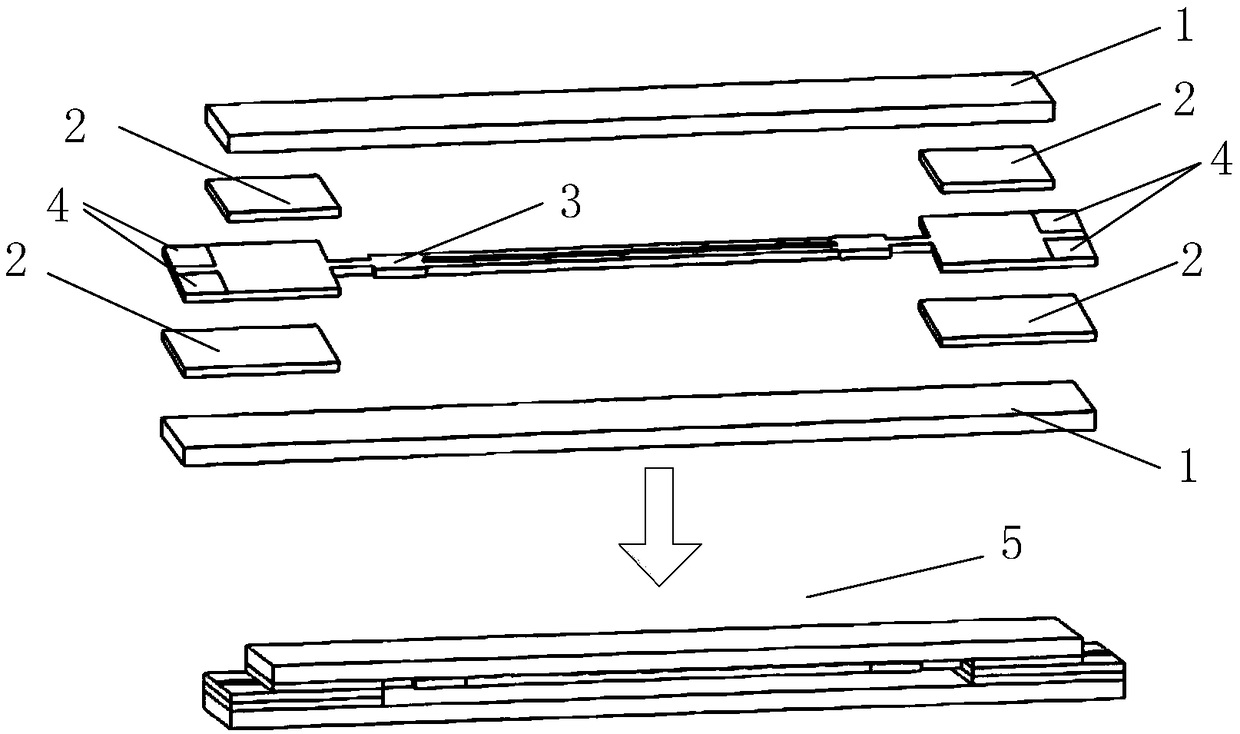

[0021] combine figure 1 , in this embodiment, the sensitive unit structure 5 of the digital frequency output resonant magnetic sensor includes two upper and lower magnetostrictive units 1 , four quartz spacers 2 and one quartz resonator 3 .

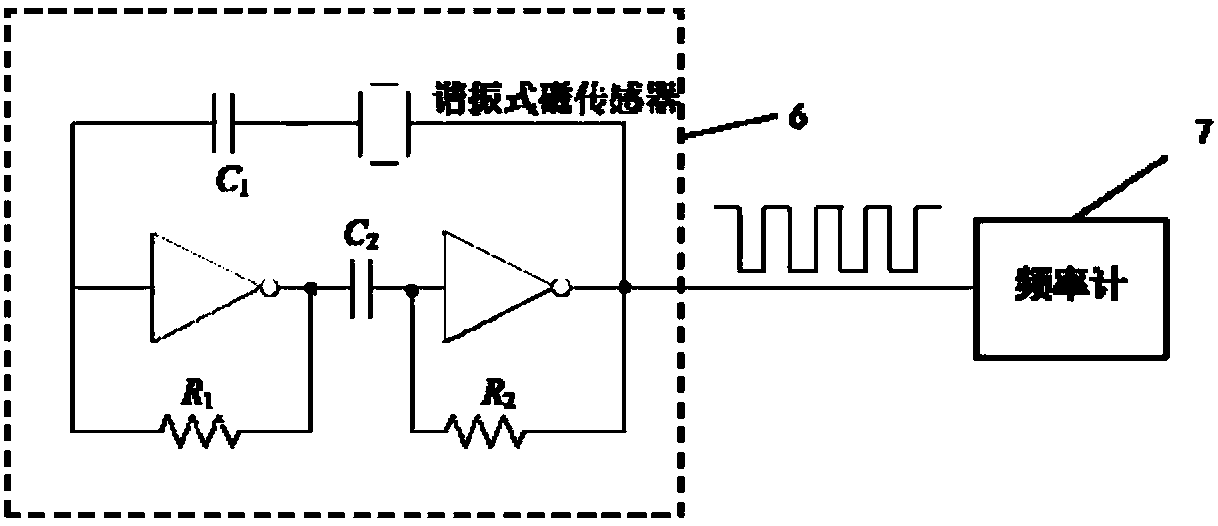

[0022] The quartz resonator 3 is a double-beam quartz tuning fork fixed at both ends, and there are electrode pads at both ends of the tuning fork for connecting to an external oscillating circuit. The quartz resonator 3 works in the bending vibration mode, and the vibration directions of the two beams are symmetrical and opposite. The electrode configuration and preparation method can be found in the literature (Kenji Sato, Atsushi Ono, et al. Experimental Study of GyroSensor Using Double-Ended Tuning Fork Quartz Resonator, 2004 IEEE International Ultrasonics, Ferroelectrics, and Frequency Control Joint 50th Anniversary Conference, pp.575-578.) or other electrode configurations that can generate symmetrical opposite bending vibration mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com