Novel CO2 photocatalytic reduction device

A technology of photocatalysis and CO2, applied in the field of photocatalysis, can solve the problems of product impurity, serious energy consumption, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

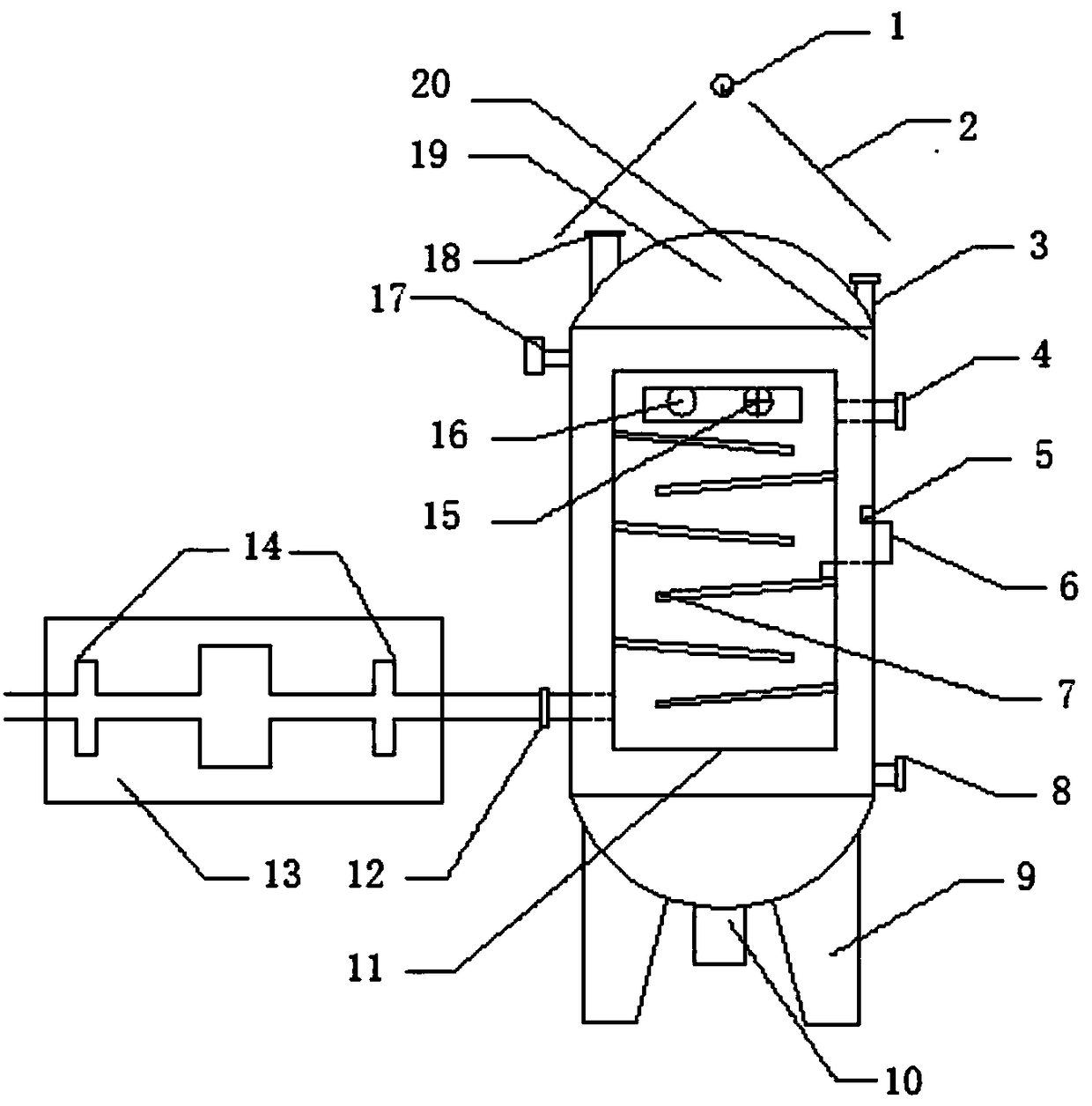

[0017] refer to figure 1 , a novel photocatalytic reduction of CO 2 The device includes a xenon lamp 1, a reflector 2, a vent valve 3, an air inlet 4, a temperature probe 5, a temperature sensor 6, a catalyst support plate 7, a water inlet 8, a foot 9, a liquid recovery port 10, a quartz glass observation window 11, Gas outlet 12, condensing device 13, gas chromatograph 14, pressure controller 15, pressure gauge 16, water outlet 17, safety valve 18, quartz glass cover 19, furnace body 20. The xenon lamp is above the quartz glass cover, the required reflector is in the middle of the xenon lamp and the quartz glass cover, a safety valve 18 is set at 1 / 6 of the edge of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com