Numerical control positioning system for door frame keyhole of steel door

A positioning system and frame lock technology, applied in positioning devices, metal processing equipment, feeding devices, etc., can solve the problems of not being able to realize fully automated production, achieve novel and unique structural composition design, improve dimensional accuracy, and have significant effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Now in conjunction with accompanying drawing, the present invention is described in detail:

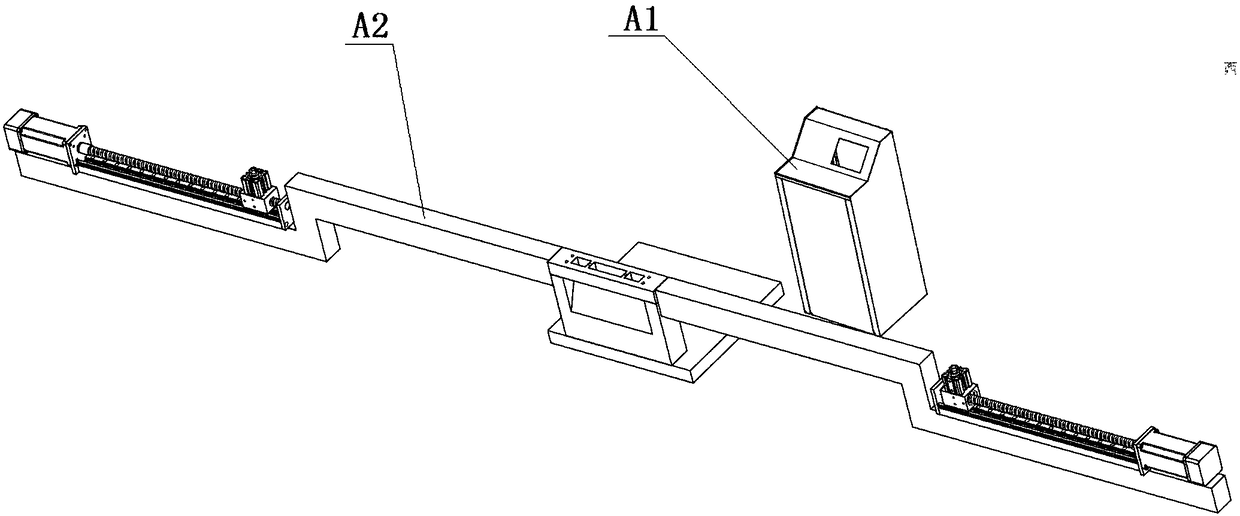

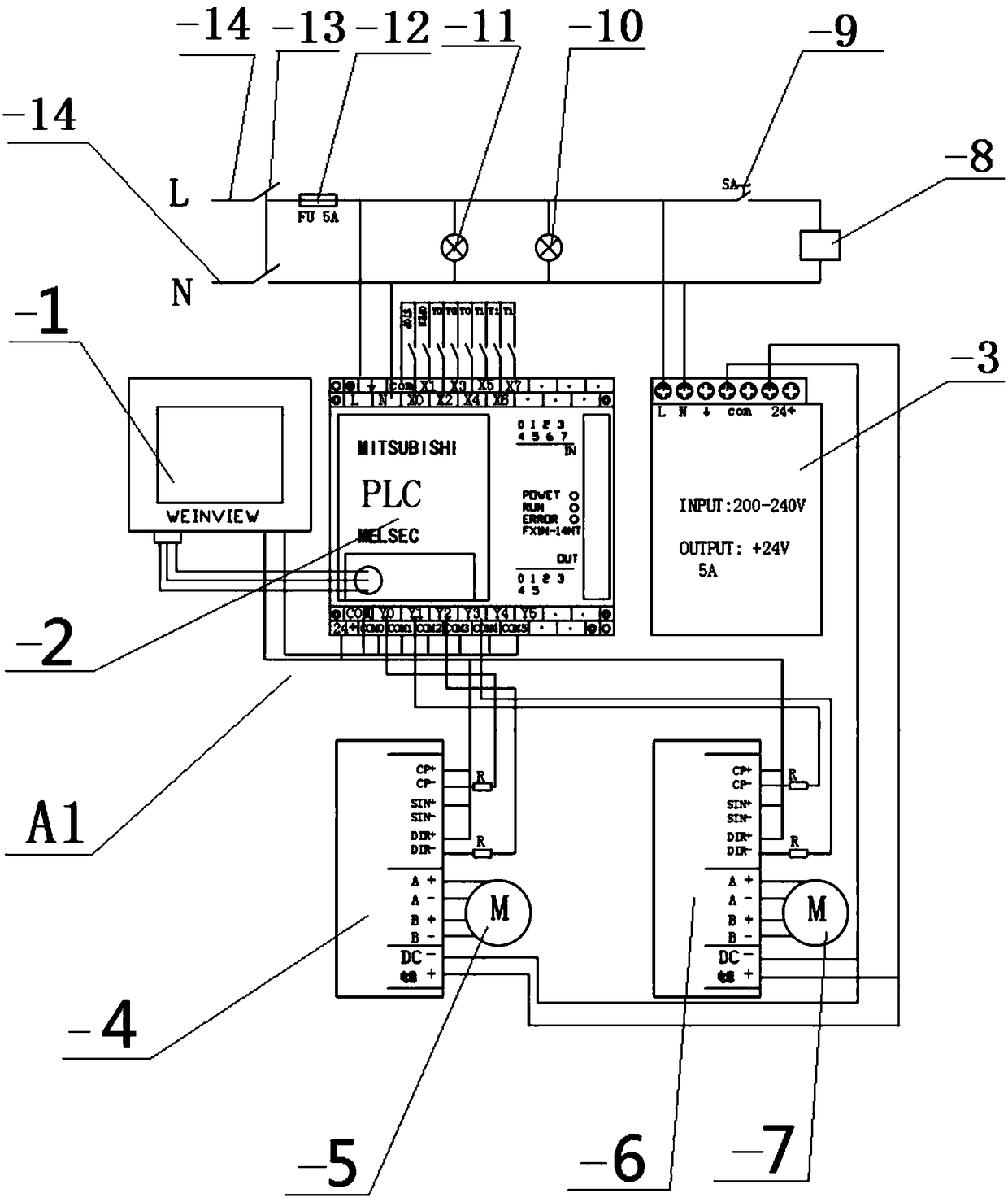

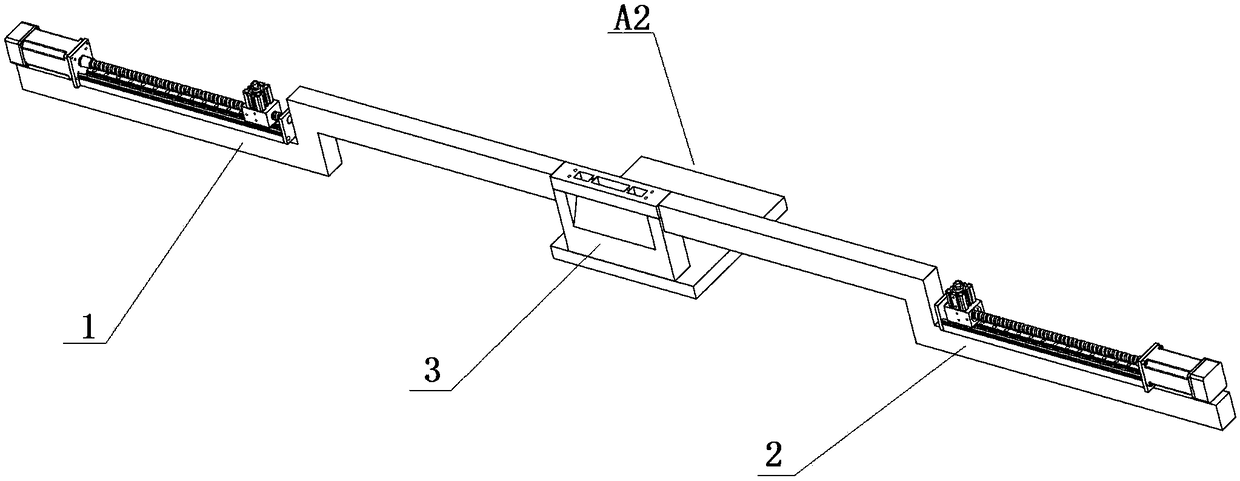

[0080] The invention is composed of a steel door frame lock hole numerical control electric control device (A1) and a steel door frame lock hole numerical control positioning device (A2).

[0081] figure 1 Shown is the structural representation of the present invention. Wherein, 1 is a left positioning mechanism, 2 is a right positioning mechanism, and 3 is a mould.

[0082] figure 2Shown is a structural schematic diagram of the electrical control device (A1) for numerically controlled positioning of the lock hole of the steel door frame in the present invention. The electrical control device (A1) for the numerical control positioning of the steel door frame lock hole is composed of a Weilun man-machine touch screen (-1), a PLC controller (-2), a switching power supply (-3), a servo motor driver (-4), Servo motor 1 (-5), servo motor driver 2 (-6), servo motor 2 (-7), solen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com