Granular organic fertilizer containing organic carbon source and preparation method thereof

A technology of granular organic fertilizer and organic carbon, applied in the direction of organic fertilizer, fertilizer made of biological waste, fertilization device, etc., can solve the problems of small change effect, environmental impact, instability, etc., so as to reduce adverse effects and improve production. Efficiency, the effect of reducing fertilizer and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

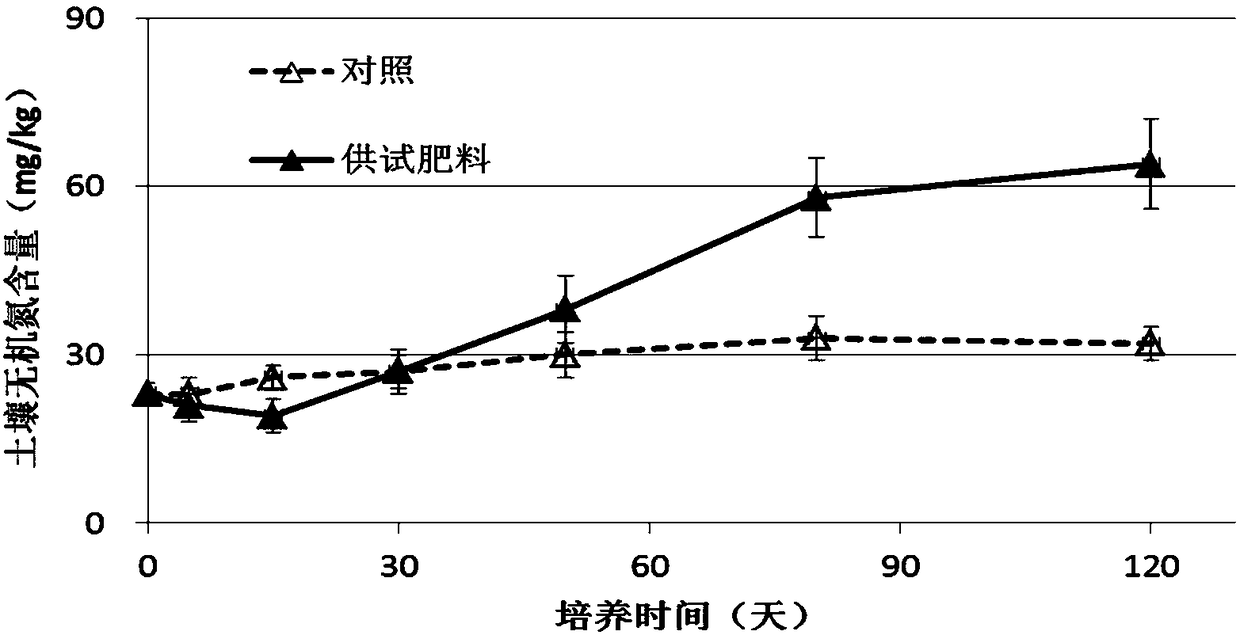

[0035]The present embodiment provides a granular organic fertilizer containing an organic carbon source, which comprises, in parts by mass, 100 parts of decomposed cow dung organic fertilizer (1.3% nitrogen content on a dry basis) with a moisture content of 30%, silage corn stalks (12% readily available organic carbon content, 30% medium available organic carbon content) 2 parts and 10 parts of mature corn stalks (4% readily available organic carbon content, 24% medium available organic carbon content).

[0036] This embodiment also provides a preparation method for the above-mentioned granular organic fertilizer, which includes the following steps: first air-dry the silage corn stalk and the mature corn stalk respectively and then pulverize them to 1 mm, then pulverize the decomposed cow dung organic fertilizer to 1 mm and adjust the water content to 30%, and then fully mix 2 parts of silage corn stalks, 10 parts of mature corn stalks and 100 parts of decomposed cow dung organ...

Embodiment 2

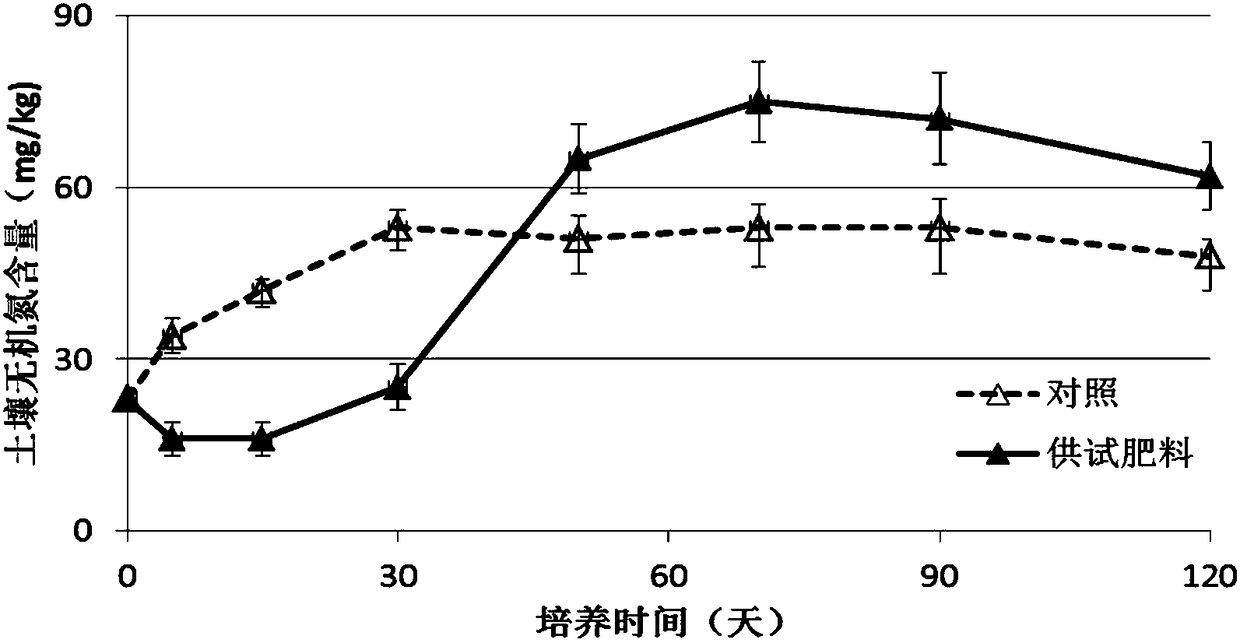

[0040] This embodiment provides a granular organic fertilizer containing an organic carbon source, in parts by mass, comprising 100 parts of enhanced cow dung organic fertilizer (with a dry basis nitrogen content of 3.5%) with a water content of 30%, silage corn stalks (15% readily available organic carbon content, 35% medium available organic carbon content) 6 parts and 4 parts of mature corn stalks (3% readily available organic carbon content, 28% medium available organic carbon content).

[0041] This embodiment also provides the preparation method of the above-mentioned granular organic fertilizer, which includes the following steps: first air-dry the silage corn stalks and mature corn stalks and pulverize them to 2mm respectively, then pulverize the strengthened cow dung organic fertilizer to 1mm and adjust the water content to 30%, then 6 parts of silage corn stalks, 4 parts of mature corn stalks and 100 parts of enhanced cow dung organic fertilizer are fully mixed to obt...

Embodiment 3

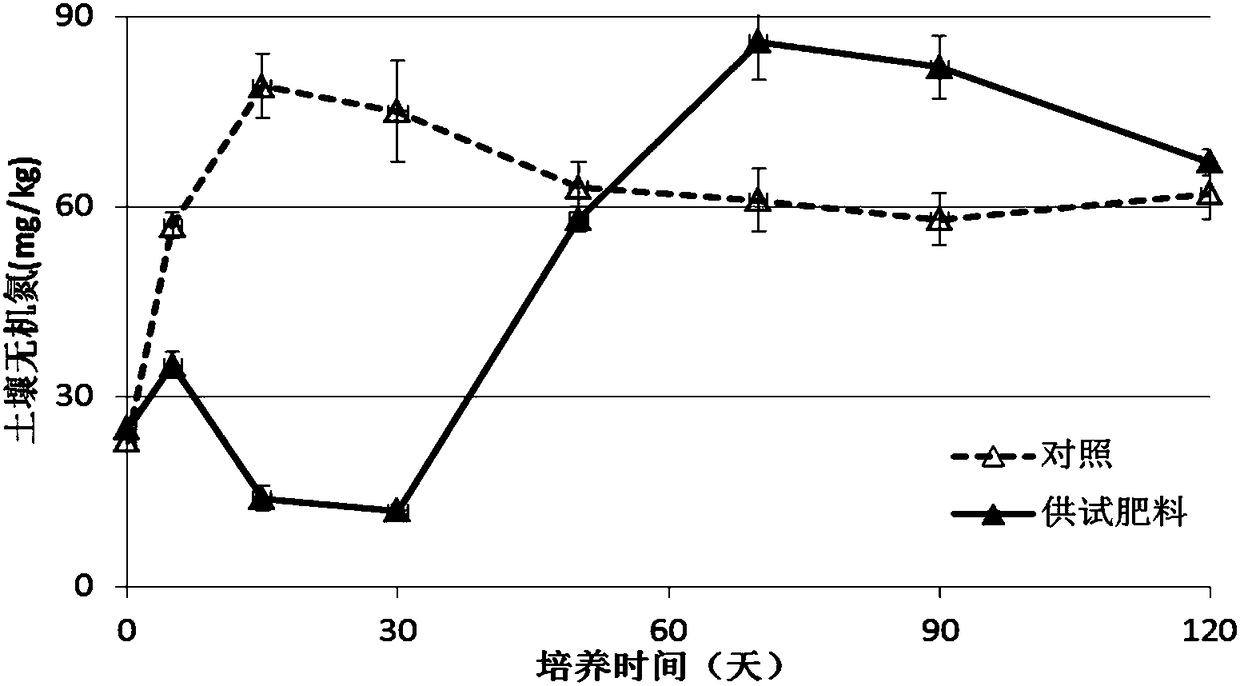

[0045] The present embodiment provides a granular organic fertilizer containing an organic carbon source, in parts by mass, comprising 100 parts of bean cake fertilizer (dry base nitrogen content of 5.5%) with a water content of 30%, silage corn stalks (easy to use Organic carbon content is 14%, medium available organic carbon content is 36%) 10 parts and mature sorghum straw (easy available organic carbon content is 5%, medium available organic carbon content is 20%) 8 parts.

[0046] This embodiment also provides a preparation method for the above-mentioned granular organic fertilizer, which includes the following steps: firstly air-dry the silage corn stalks and mature sorghum stalks and pulverize them to 2mm respectively, then pulverize the bean cake fertilizer to 1mm and adjust the water content to 30%. Then fully mix 10 parts of silage corn stalks, 8 parts of mature sorghum stalks and 100 parts of bean cake fertilizer to obtain a mixed material, and finally use a disc gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com