Unbleached and non-dyed knitted cotton textile prepared by ecological cleaning method

A cotton textile and clean technology, applied in the field of knitted cotton textiles, can solve the problems of not conforming to modern environmental protection, difficult to remove, and reduced enzyme activity, and achieve the effects of reducing damage to the human body, protecting the environment, and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

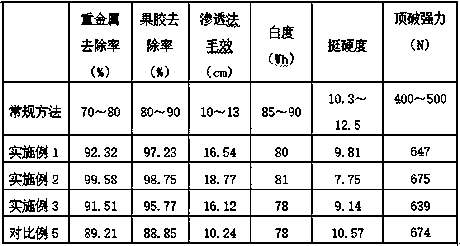

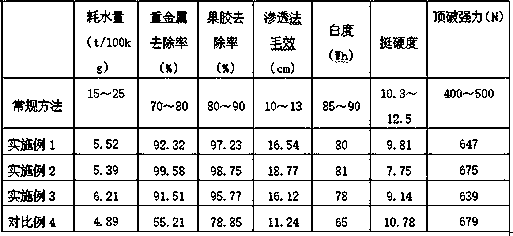

Examples

Embodiment 1

[0054] Example 1 An unbleached and undyed knitted cotton textile prepared by an ecological cleaning method, the preparation process comprising:

[0055] (1) Pre-washing of knitted cotton textiles

[0056] Soak the knitted cotton textiles to be treated in a clear water environment system about 30 times the weight of the knitted cotton textiles, so that the knitted cotton textiles to be treated are completely infiltrated; then, the water temperature of the clear water environment system is raised to 30°C, and lipase is added, Carry out heat preservation treatment; Knitted cotton fabric is pure cotton fabric (100% cotton, gram weight 190g / m 2 , friction coefficient 3-4, bursting strength ≥ 500N); the amount of lipase in the clean water environment system is 0.5g / L; Fully react with lipids or other oily impurities on knitted cotton textiles to form water-soluble alcohols, fatty acids and other water-soluble impurities and remove them. The lipase is acid lipase; the enzyme activi...

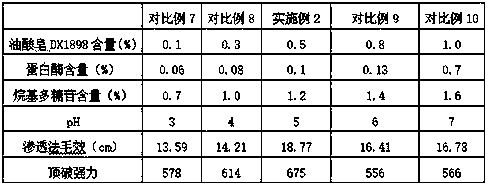

Embodiment 2

[0070] Embodiment 2 An unbleached and undyed knitted cotton textile prepared by an ecological cleaning method, the preparation process comprising:

[0071] (1) Pre-washing of knitted cotton textiles

[0072] Soak the knitted cotton textiles to be treated in a clean water environment system about 30 times the weight of the knitted cotton textiles, so that the knitted cotton textiles to be treated are completely infiltrated; then, the water temperature of the clean water environment system is raised to 50°C, and lipase is added. Carry out heat preservation treatment; knitted cotton textiles are pure cotton fabrics (100% cotton, weight 190g / m 2 , friction coefficient 3-4, bursting strength ≥ 500N); the amount of lipase in the clean water environment system is 2g / L; Grease or other oily impurities on knitted cotton textiles are fully reacted into water-soluble alcohols, fatty acids and other water-soluble impurities to be removed. The lipase is acid lipase; the enzyme activity o...

Embodiment 3

[0087] Example 3 An unbleached and undyed knitted cotton textile prepared by an ecological cleaning method, the preparation process of which comprises:

[0088] (1) Pre-washing of knitted cotton textiles

[0089] Soak the knitted cotton textiles to be treated in a clean water environment system about 50 times the weight of the knitted cotton textiles, so that the knitted cotton textiles to be treated are completely infiltrated; then, the water temperature of the clean water environment system is raised to 40°C, and lipase is added, Carry out heat preservation treatment; knitted cotton textiles are pure cotton fabrics (100% cotton, weight 190g / m 2 , friction coefficient 3-4 grades, bursting strength ≥ 500N); the amount of lipase in the clear water environment system is 2g / L; Grease or other oily impurities on knitted cotton textiles are fully reacted into water-soluble alcohols, fatty acids and other water-soluble impurities to be removed. The lipase is acid lipase; the enzym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com