Subgrade construction method for aeolian sand section and structure and device thereof

A construction method and technology of aeolian sand, applied in the direction of roads, roads, road repair, etc., can solve the problems of aeolian sand road construction materials that cannot be compacted, desertification, aggravated soil erosion, increased manpower, material resources, and financial resources, etc. The effect of reducing the cost of abandonment, good quality and low construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

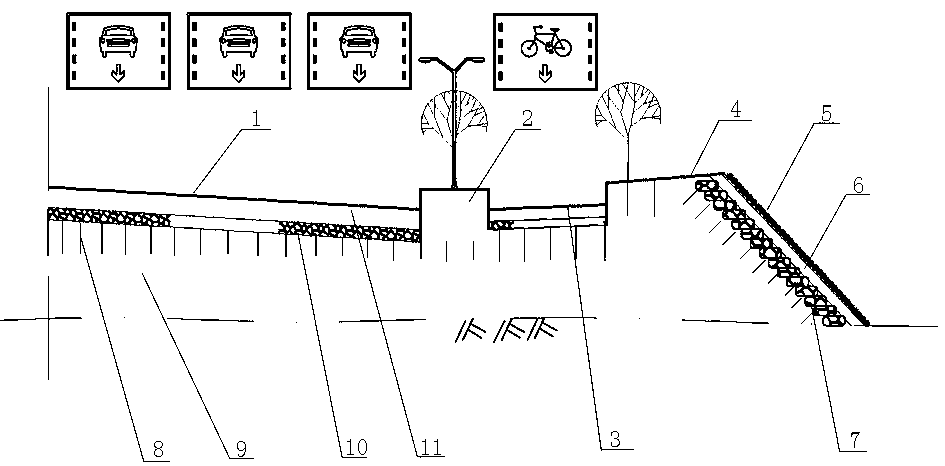

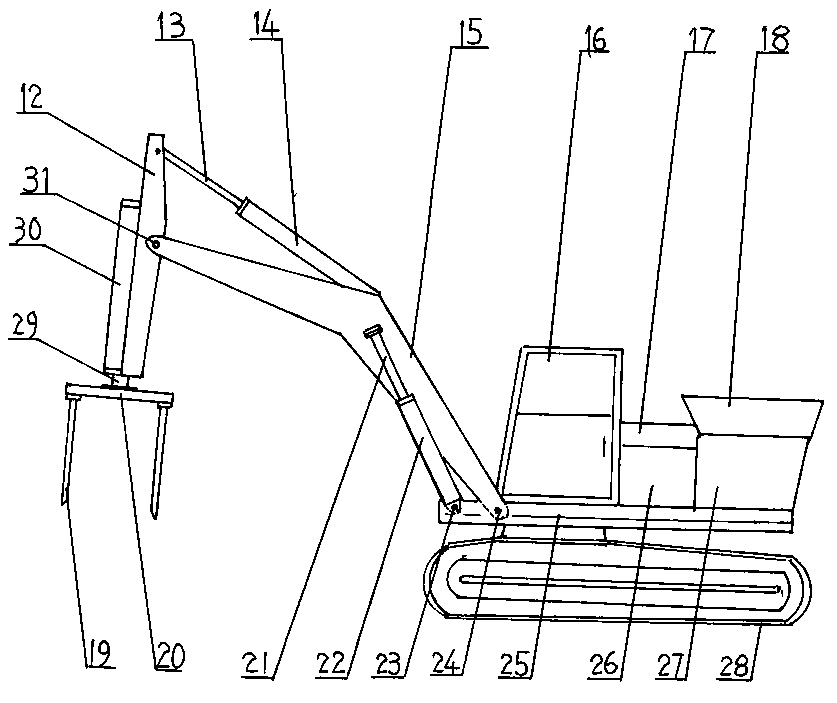

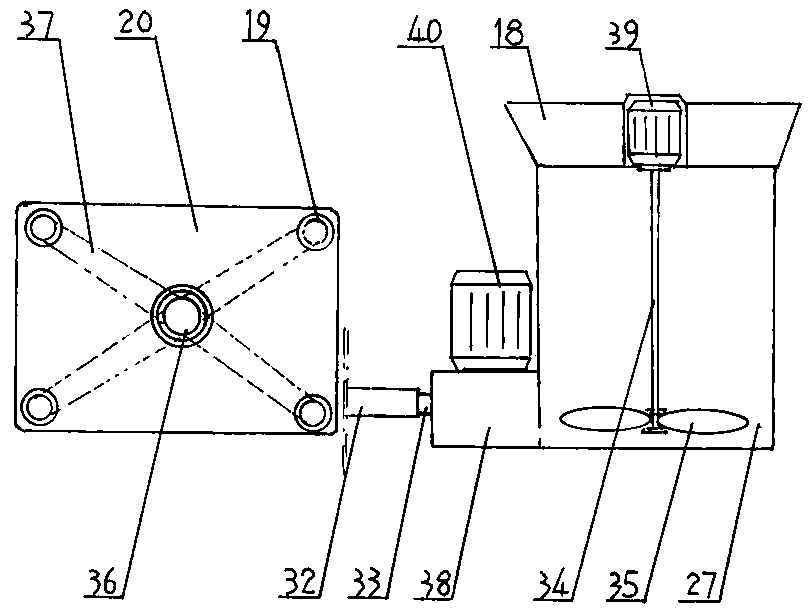

[0051] Such as Figure 1 to Figure 5 As shown, a subgrade construction method for aeolian sand section includes the following steps:

[0052] (1) Construction preparation: Prepare a fast sand-fixing column construction machine, stake out the road centerline and roadbed sideline, and use a bulldozer or loader to clean up the topsoil, tree roots, dead wood, and various types of garbage, and clean up the impurities in the filling materials. things.

[0053] (2) Filling sampling test: Before the aeolian sand filling layer is paved, the aeolian sand filling shall be sampled and tested to determine its maximum dry density and optimal moisture content indicators.

[0054] (3) Shipment of aeolian sand: Double-axle dump trucks are used to transport aeolian sand, and the vehicles are loaded less frequently, and the moisture content on the surface of the filler is kept at 10% to 13%. When the surface of qualified aeolian sand continues to be filled, water must be sprinkled to keep the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com