Composite steel formwork support system and construction method thereof

A technology of support system and construction method, which is applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of difficult quality control of underground structure construction, poor economic and environmental protection, and poor concrete appearance quality, so as to reduce crane cranes. time and worker operation time, good appearance, and convenient reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

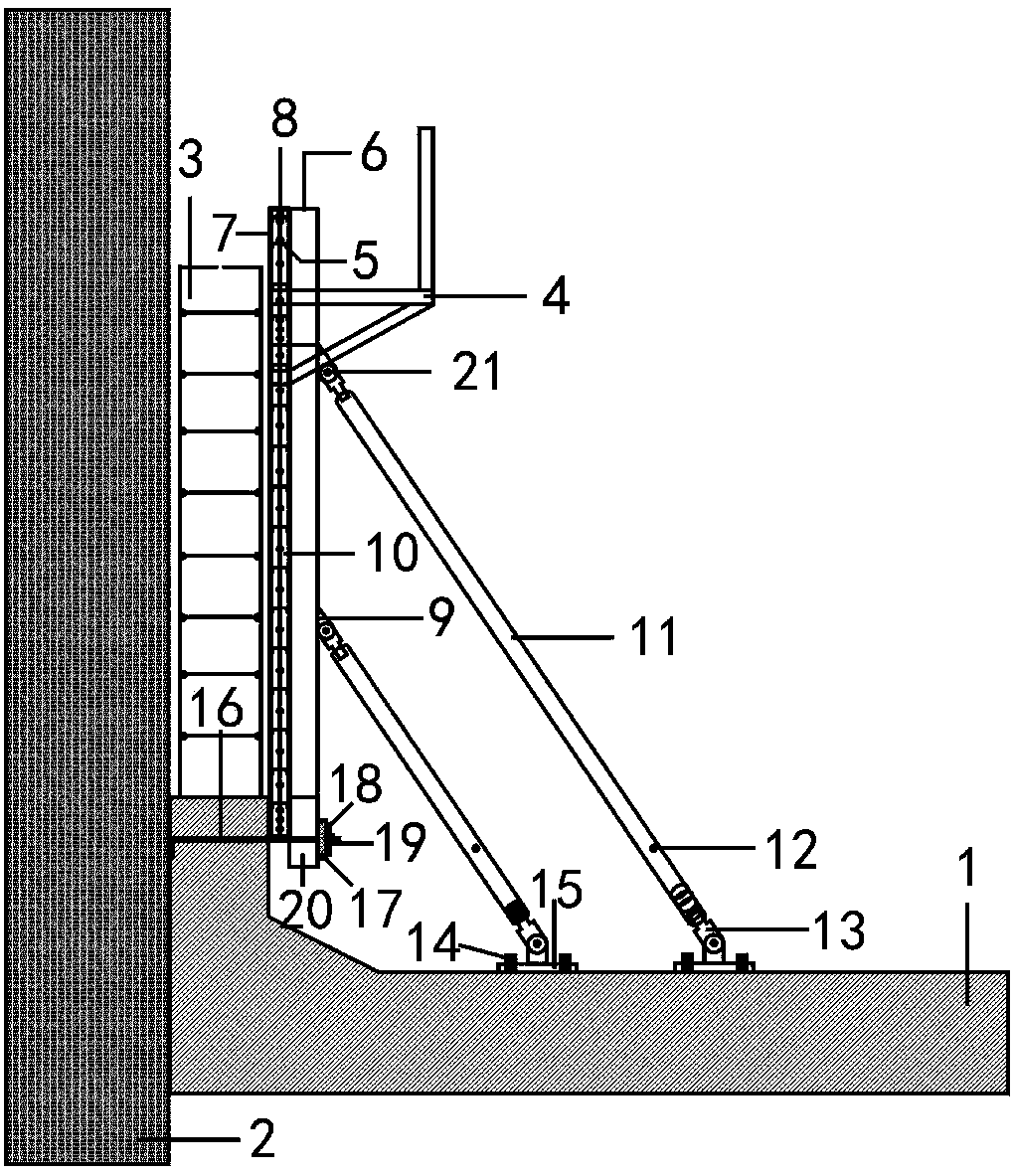

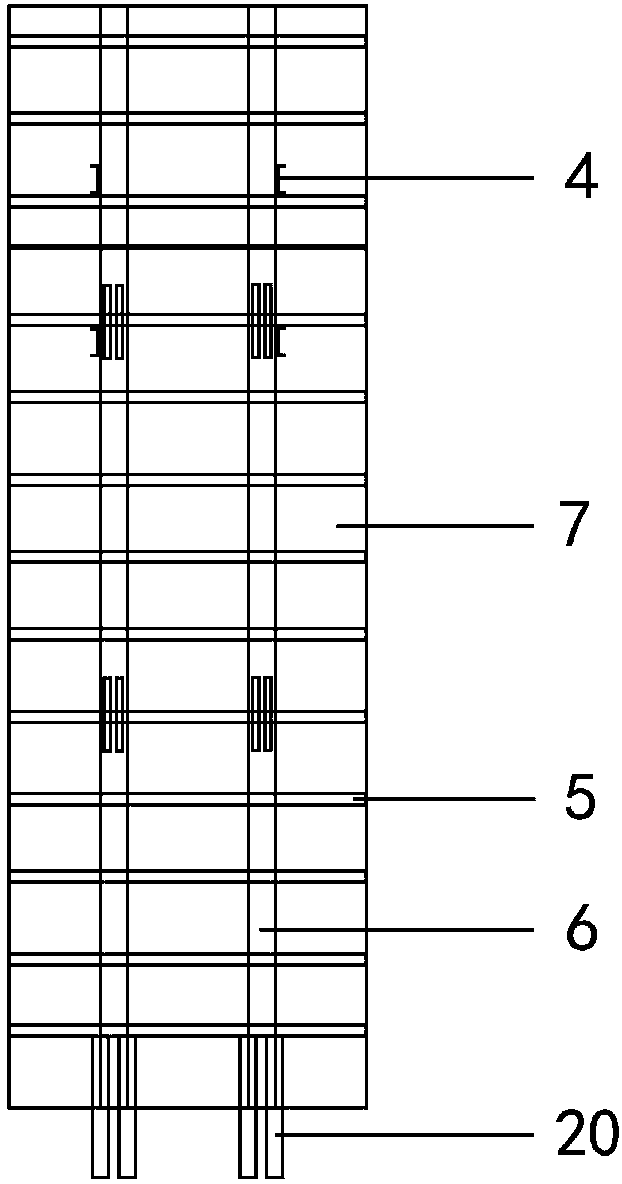

[0032] The combined steel formwork support system and construction method thereof according to the present invention are mainly used for assisting the side wall construction of underground structures (such as subway stations, comprehensive pipe corridors, etc.), and the structural bottom plate of the side wall needs to be made before the side wall construction 1 or structural mid-slab, or a solid concrete structure under the side walls. The combined steel formwork support system is fixed on one end of the structural bottom plate 1 or the middle plate of the structure, and the combined steel formwork support system is arranged opposite to the enclosure structure 2; It is the construction joint of the side wall, and the two sides of the construction joint of the side wall are provided with stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com