Large underground fuel gas storage device

A gas storage device and gas technology, which can be applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, ship construction details, etc. Unbalanced gas consumption and other problems, to achieve the effect of long service life, convenient use and management, and solving the problem of reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

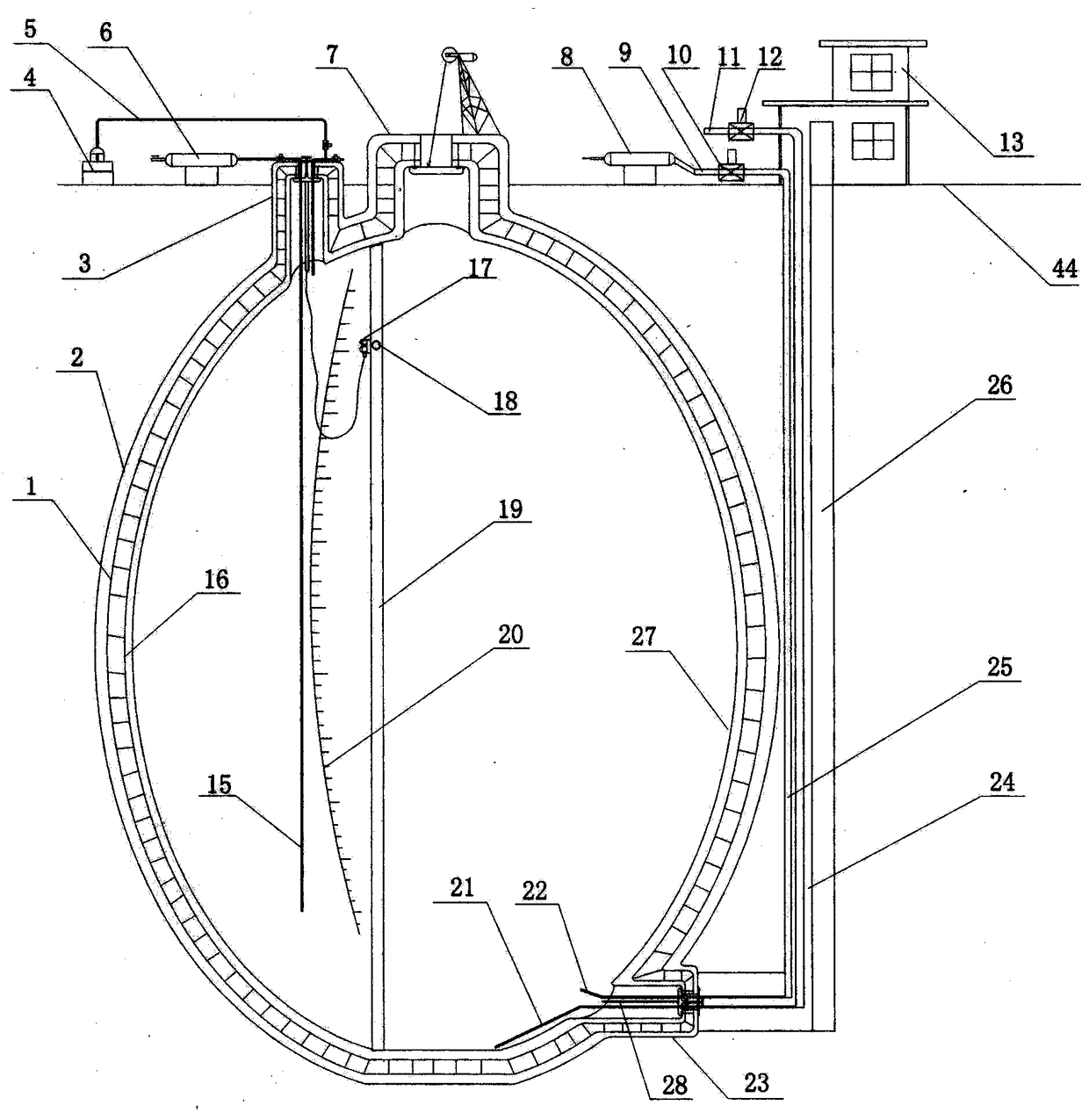

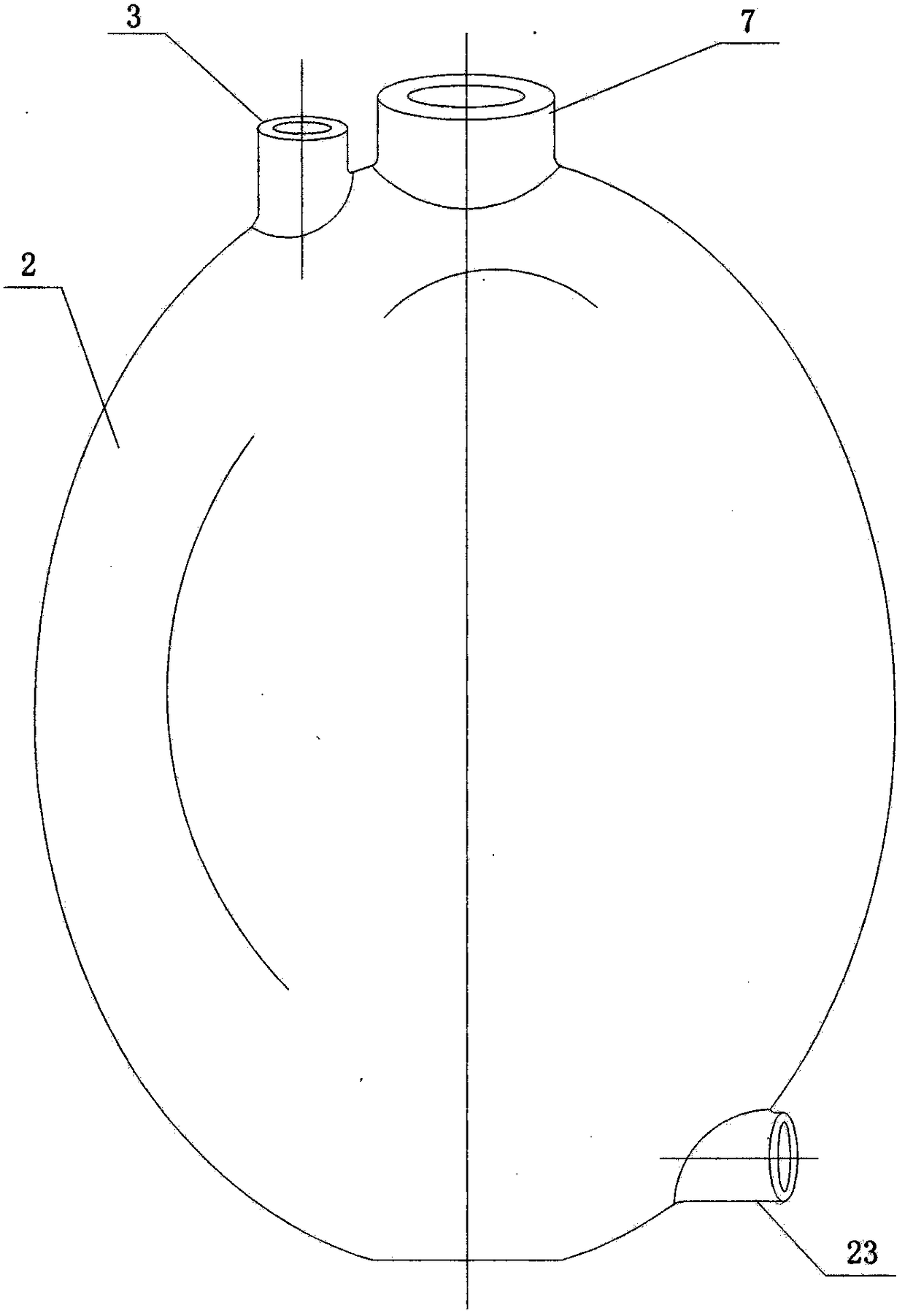

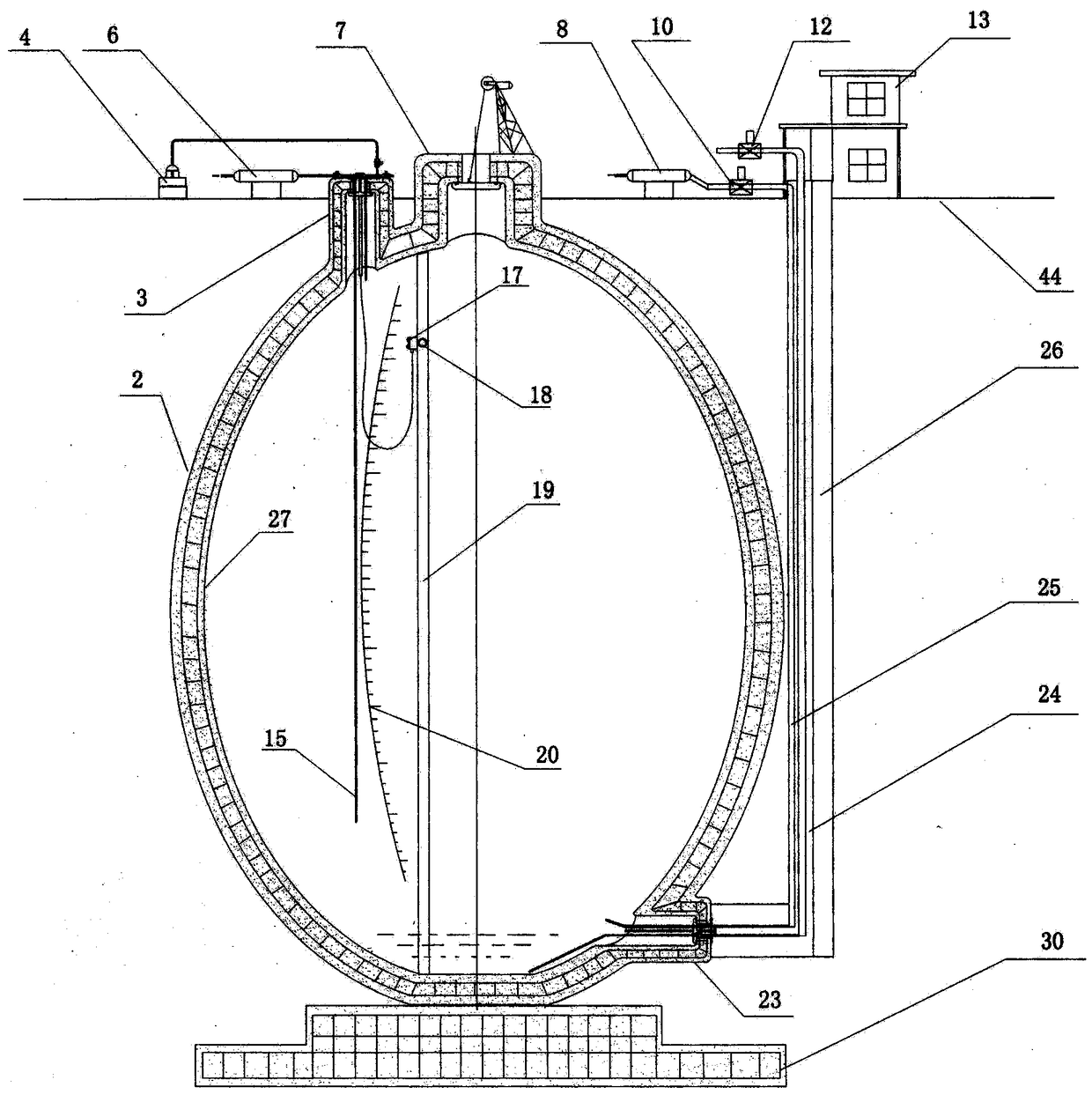

[0048] Its shape and structure are as figure 1 , figure 2 with image 3 As shown, the tank body 2 of the gas storage device is filled with composite soil, such as Figure 4 As shown, first calculate the size of the gas storage tank according to the designed gas storage capacity. Taking the medium-sized city of Zhengzhou as an example, the daily natural gas consumption in Zhengzhou is calculated as 6 million cubic meters, and the volume of LNG is about the volume of the same amount of gaseous natural gas. 1 / 600. If you plan to reserve the gas consumption for one day, you need to build a 10,000 cubic gas storage tank with an inner diameter of 26 meters. The design pressure of the LNG filling station storage tank is 1.6MPa, the operating pressure is 1.2MPa, and the actual normal working pressure is between 0.4-1.0MPa. The tank wall thickness here is 40cm, and the pressure is greater than 10MPa, which is much higher than the pressure requirement of the ground gas storage tank....

Embodiment 2

[0055] Its principle and structure are basically the same as in Embodiment 1, except that nail-shaped grooves 34 are processed on the cement surface inside the tank body 2, and a spray film layer 35 is attached, such as Figure 8 As shown, the smoothness inside the tank body 2 is increased, and the generation of impurities inside the tank body 2 is reduced. When pouring cement 33, put nails on the shell plate, the length of the nails protruding from the shell plate is 0.5 cm, and the distance between the nails is 30 cm. When the cement is not dry, remove the shell plate with nails Next, in the inside of the tank body 2, the nail-shaped groove 34 with a pitch of 30 centimeters and a depth of 0.5 centimeters has been left. After the cement project is completed, the scum on the inner surface of the tank is cleaned up, and the heat-spraying process is used to spray the heat-shrinkable film with a thickness of about 0.5 mm.

[0056] The large-scale underground gas storage device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com