Testing system and testing method for tire slip amount based on edge-enhanced recognition

A test system and edge enhancement technology, applied in the direction of automobile tire testing, etc., can solve the problems of inaccurate judgment of tire contact boundary, different systems, complicated operation, etc. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

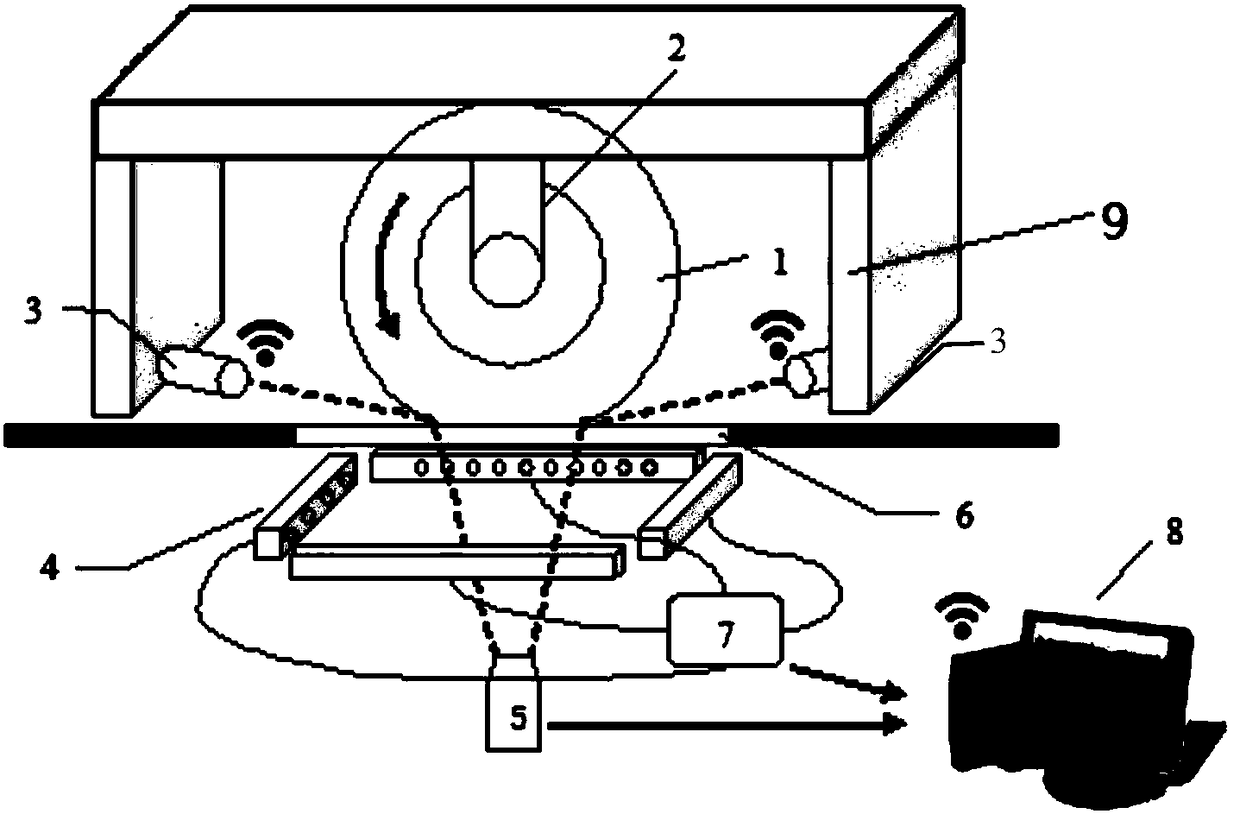

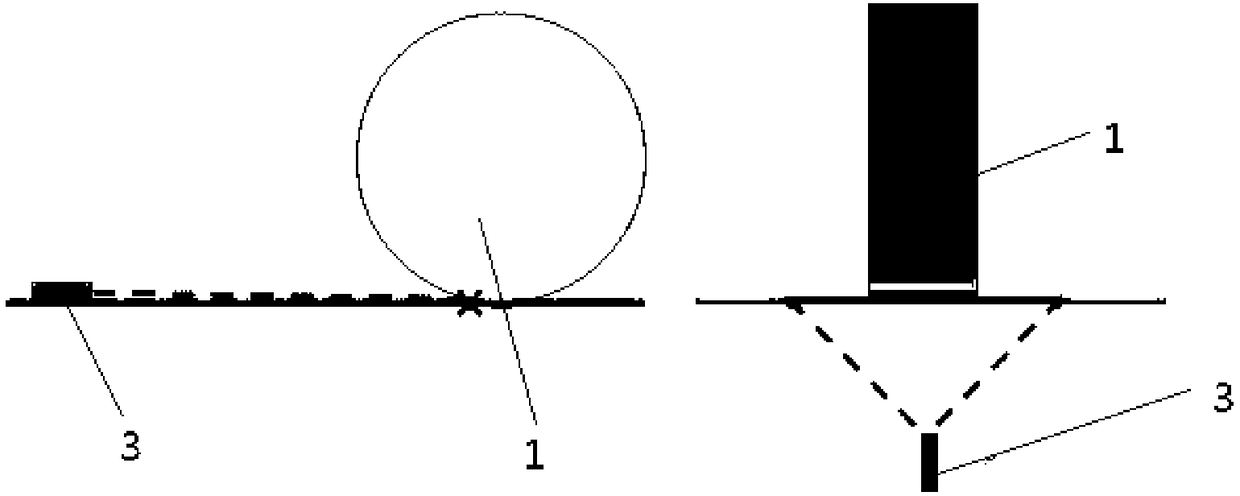

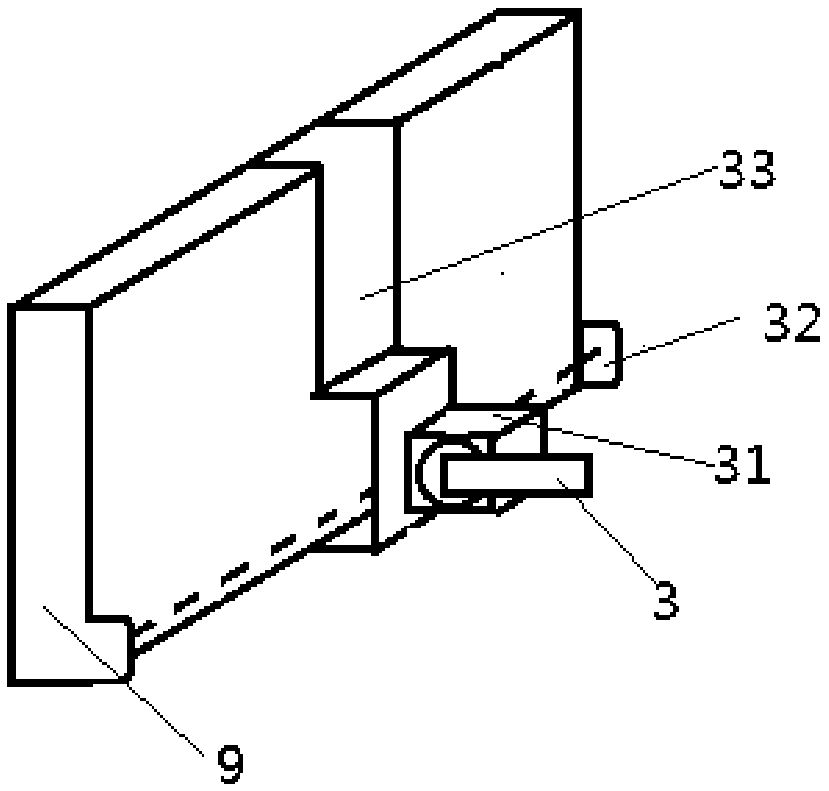

[0027] Such as Figure 1-3 As shown, the tire slippage test system based on edge enhancement recognition includes a test bench and a workstation 8, the test bench is a test bench including a glass platen 6, a frame 9 is set on the glass platen 6, and a tire 1 is arranged in the frame 9, The tire 1 is connected with a rolling control mechanism 2 to control the movement of the tire 1. A font laser 3 is arranged on the side wall of the corresponding frame 9 along the rolling direction of the tire 1. The bottom of the glass platen 6 is in contact with the glass platen 6 to surround the tire 1. A circle of LED lighting lamps 4 is arranged on the surface, that is, four strip LED lighting lamps are used to form a rectangle, and a camera 5 is arranged under the glass platen 6 facing the contact surface between the tire 1 and the glass platen 6. The camera 5 In order to support a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com