Heat pipe cooling dry-type transformer

A transformer and transformer box technology, applied in the field of transformers, can solve the problems of heavy equipment manufacturing efficiency, low natural heat dissipation efficiency, increased material costs, etc., and achieve the effects of light weight, effective use of space, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

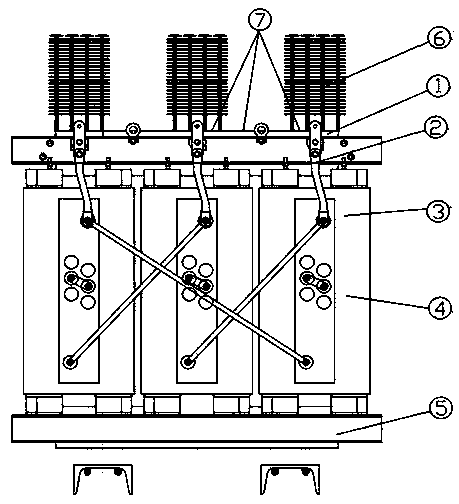

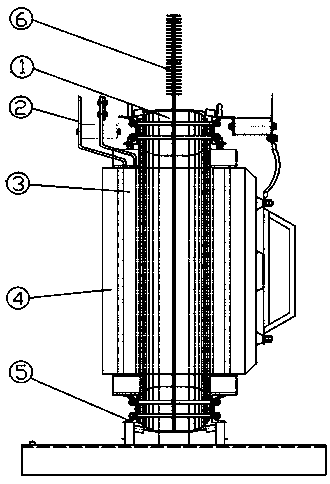

[0019] Accompanying drawing is a kind of specific embodiment of the present invention.

[0020] The heat pipe cooling dry-type transformer of the present invention includes an iron core 1, a low-voltage coil 3 and a high-voltage coil 4 installed on the iron core, clamps 5 are fixed on the outer sides of the upper and lower ends of the iron core, and they are installed in the transformer box. A microcontroller and a transformer temperature controller are installed on the body, and the transformer temperature controller is connected to the microcontroller; a superconducting heat pipe 6 is fixed on the iron core.

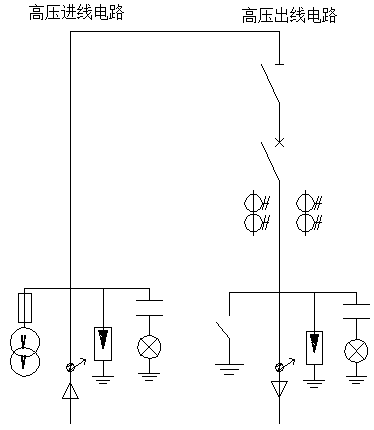

[0021] The high-voltage coil is connected to the high-voltage control cabinet, and the high-voltage control cabinet has a primary transformer system circuit, which includes a high-voltage outgoing line circuit and a high-voltage incoming line circuit connected to each other.

[0022] The high-voltage incoming line circuit includes a first branch, a second branch, a thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com