Air humidity control system and method of proton exchange membrane fuel cell

A proton exchange membrane and fuel cell technology, applied in fuel cells, electrical components, circuits, etc., can solve problems such as only applicable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

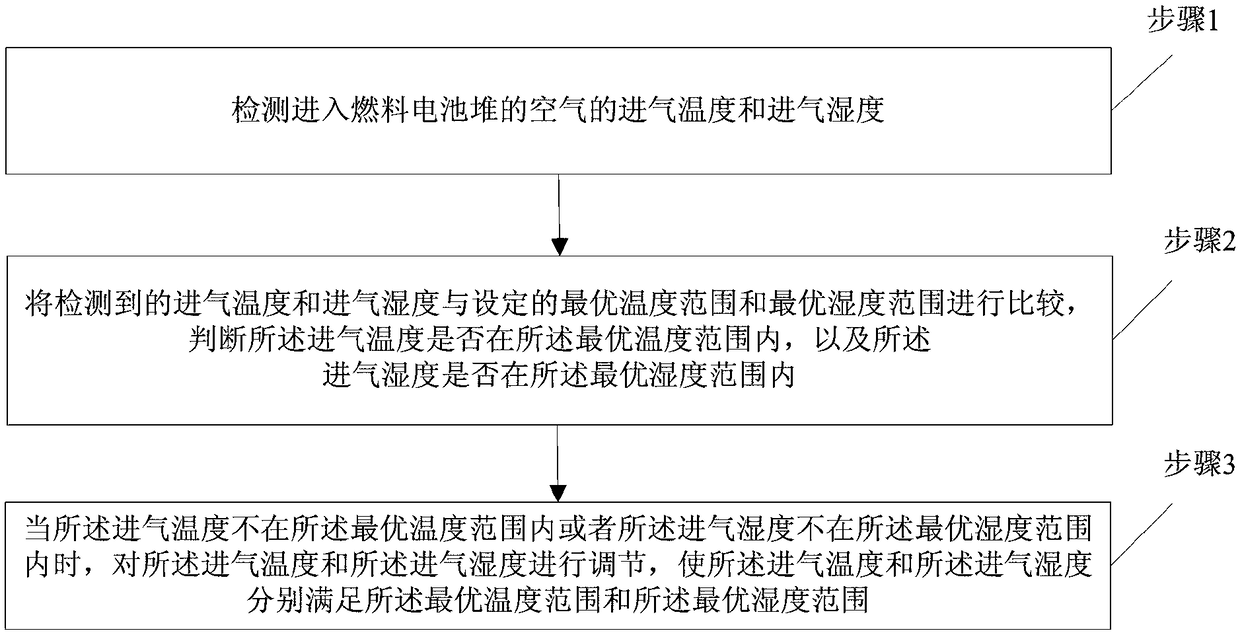

[0062] Such as Figure 5 , the humidification system used in this embodiment includes an air compressor 1 , an intake air temperature control unit 2 , an enthalpy wheel humidifier 3 , a temperature sensor 4 , a humidity sensor 5 and a fuel cell stack 6 .

[0063] The core component of the enthalpy wheel humidifier 3 is a porous ceramic runner, the surface of which is covered with a layer of water-absorbing material. The enthalpy wheel humidifier 3 includes the inlet and outlet of fresh air and the inlet and outlet of hot and humid exhaust gas, and the ceramic runner rotates under the drive of the motor during operation. When the hot and humid exhaust gas of the fuel cell passes through one side of the humidifier, the ceramic runner absorbs the moisture in the exhaust gas and stores it on its surface, and then rotates to the other side of the humidifier; when fresh air enters the enthalpy wheel humidifier 3, it absorbs the porous ceramic surface The water is taken away to comp...

specific Embodiment 2

[0068] Such as Figure 6 , this embodiment includes an air compressor 1 , an intake air temperature control unit 2 , a liquid water jet humidifier 11 , a temperature sensor 4 , a humidity sensor 5 and a fuel cell stack 6 .

[0069] The humidification method adopted by the liquid water jet humidifier 13 is to use high pressure to atomize water through the spray nozzle, spray it into the air flow, and evaporate the water to obtain air with a certain relative humidity. Liquid water jet humidification can control the humidification amount by adjusting the gas flow, water spray pressure, water temperature, etc. In this embodiment, the method of controlling the water spray pressure is used to adjust the relative humidity of the air.

[0070] The fresh air first passes through the air compressor 1, and the airflow after passing through the air compressor 1 needs to be temperature controlled by the intake temperature control unit 2. After passing through the intake temperature control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com