Modular contact component and large transmission slip ring contact device based on component

A contact assembly and contact device technology, applied in the direction of circuits, current collectors, electrical components, etc., can solve the problems of limited current transmission capacity, poor anti-vibration performance, and low reliability of a single contact, and achieve simplified installation and debugging. Maintaining the process, increasing overall reliability, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

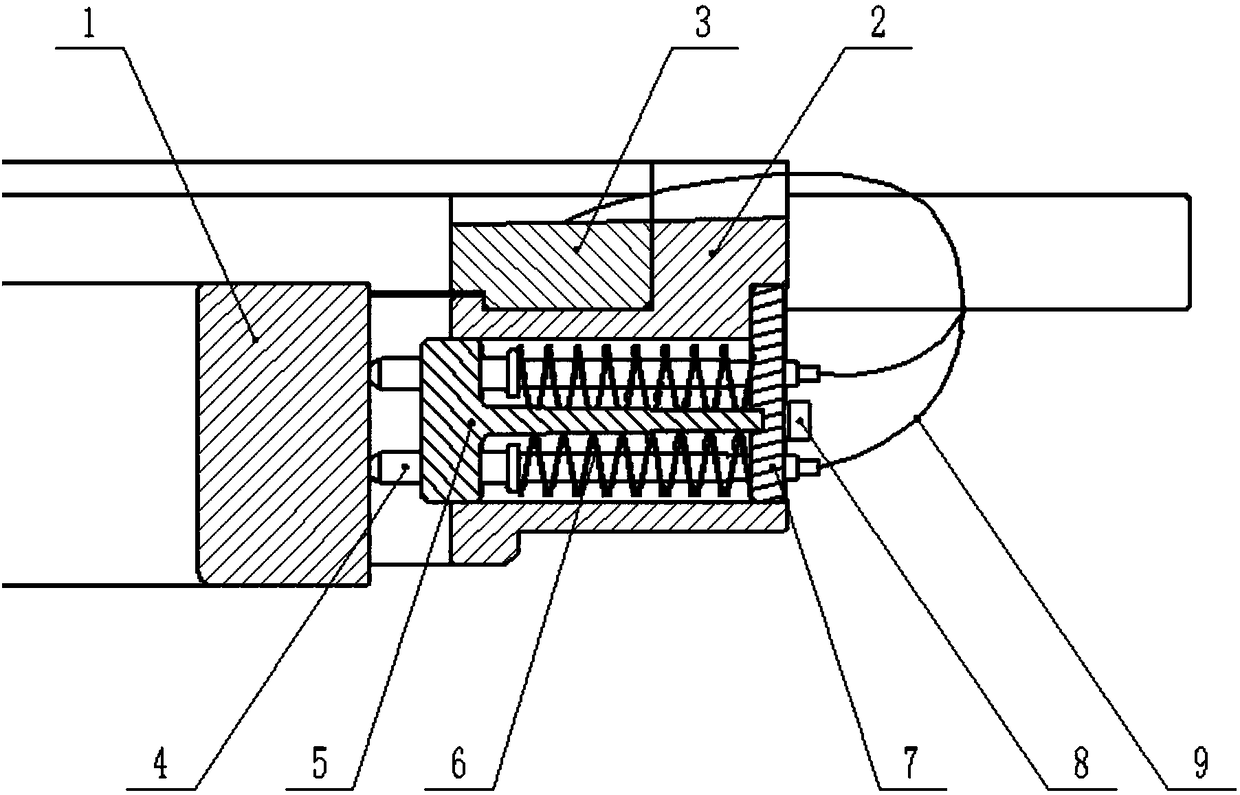

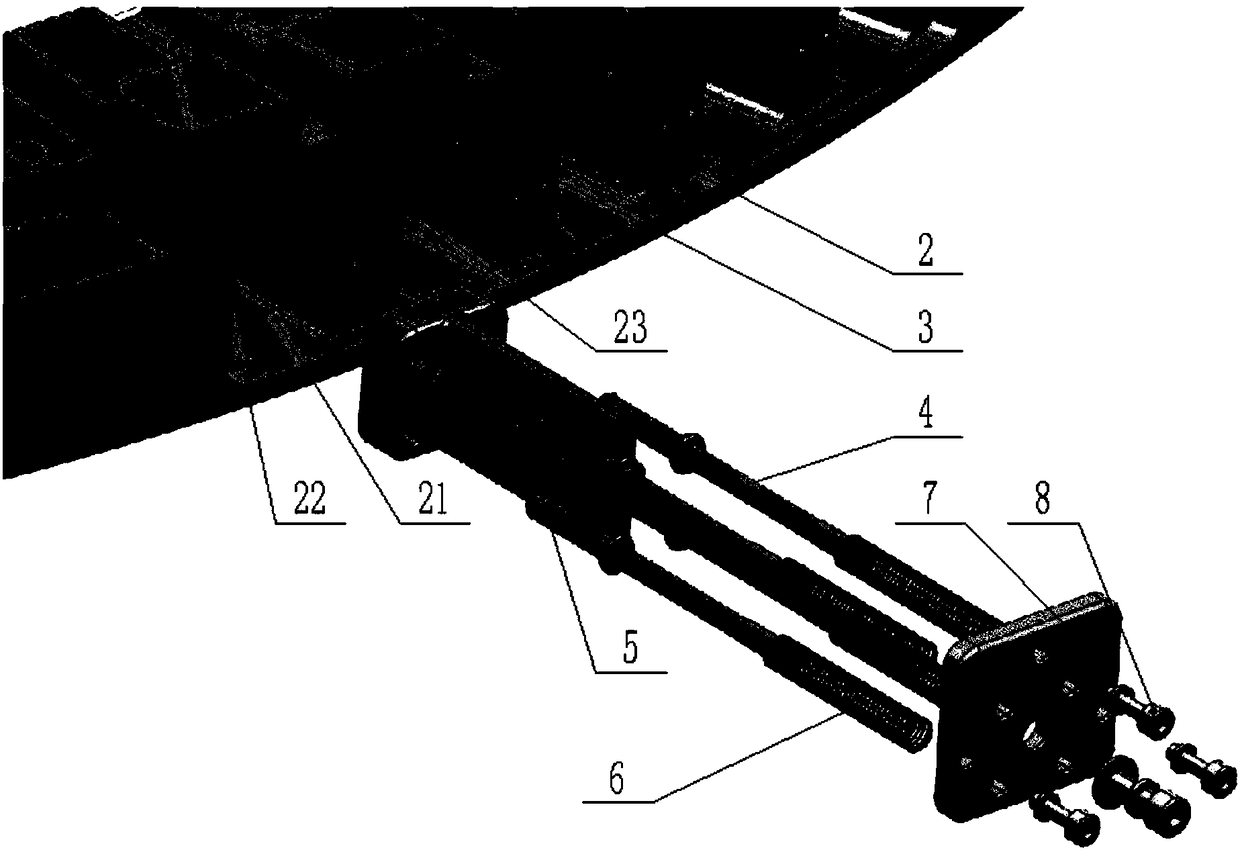

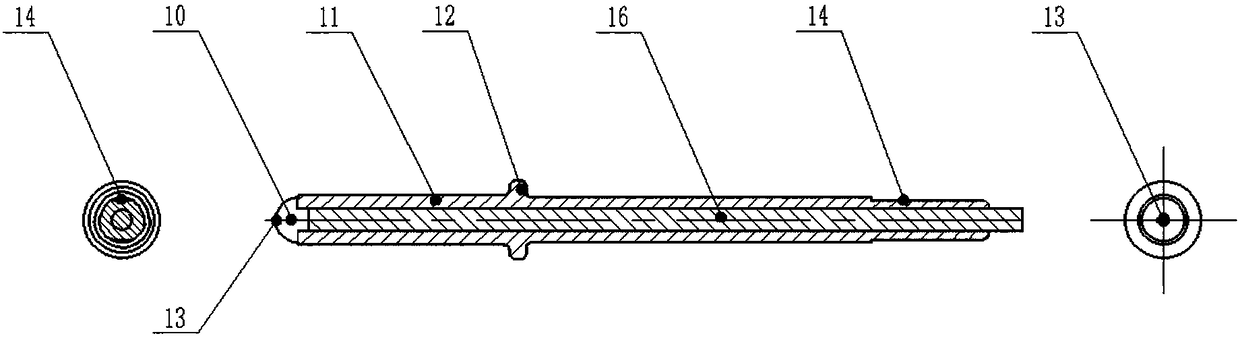

[0023] Such as figure 1 , 3 , 4 and 5, the modular contact assembly includes four movable contacts 4, a contact guide seat 5, four elastic elements 6, a baffle 7, a fastener 8, and four wires 9, The movable contact 4 is composed of a precious metal contact 10, a guide rod 11 and a conductive core 16, wherein the precious metal contact 10 is located at one end of the guide rod 11, and the conductive core 16 is located inside the guide rod 11 and is directly connected to the precious metal contact 10. The guide rod 11 is a conductive and wear-resistant material. The cylindrical shape design reduces the volume and mass of the movable contact. In this way, the impact of vibration on the movable contact is reduced under the same elastic pressing force. And in the case of ensuring a certain resonance frequency of the movable contact 4, an elastic element with a small elastic coefficient can be selected to ensure that the movable contact 4 is under radial runout caused by the form and ...

Embodiment 2

[0026] In the second embodiment, on the basis of the first embodiment, the tail end of the guide rod 11 is designed as a waist-shaped cross-section rod 14, and the contact fixing hole 15 of the baffle 7 is designed as a waist-shaped hole, which cooperate with each other to better limit the movable contact. Point 4 is the degree of freedom to rotate in the axial direction. The waist hole 15 can be equipped with gaskets of different thicknesses to adjust the compression of the elastic element to adjust the pre-tightening force.

Embodiment 3

[0028] In Embodiment 3, on the basis of Embodiment 1 or 2, the precious metal contact 10 is designed as a hemispherical stamped part with a flat end surface 13 on the top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com