Cooling system based on slab laser

A technology of slab laser and heat dissipation system, applied in the field of lasers, can solve the problems of inability to work under weightless conditions, large size of the whole machine, etc., and achieve the effects of reducing thermal lens effect, flexible laser, and reducing overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

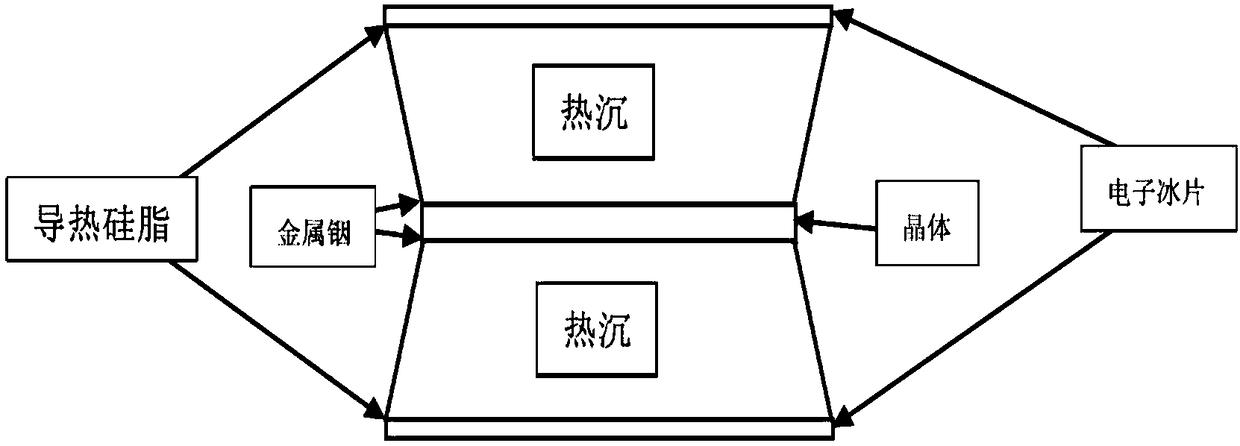

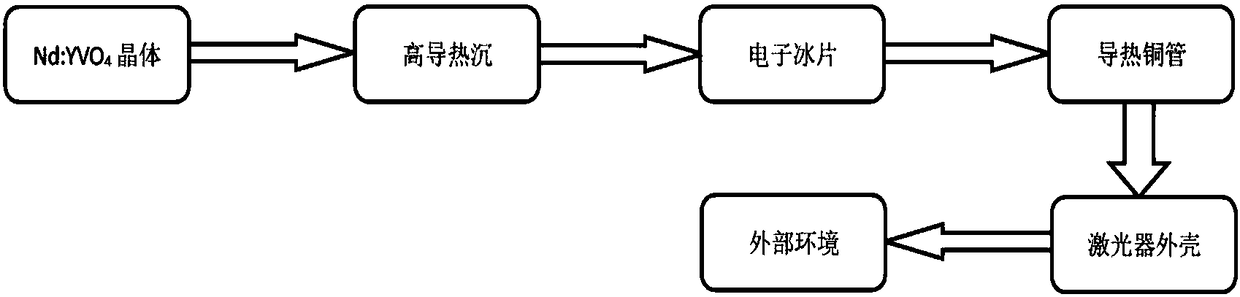

[0018] Such as Figure 1-2 As shown, the present invention provides a slab-type laser-based electronic ice sheet heat dissipation system, including: Nd:YAG crystal, mirror group, high thermal conductivity heat sink, and tec chip. In order to reduce the thermal contact resistance between the thermal interfaces, it needs to be controlled from multiple aspects and multiple means. The specific implementation methods are:

[0019] The upper and lower sides of the Nd:YAG crystal are respectively combined with high thermal conductivity heat sinks, and a heat conduction pad is used between the high heat conduction heat sinks to avoid damage. The thickness of the heat conduction pad is 0.2-0.5mm;

[0020] The surface morphology and dimensional accuracy control of the thermal interface, here controls the accuracy of the upper and lower surfaces of the heat sink, generally speaking, the roughness should be less than 1.6, and the flatness should be less than 0.1mm / 100mm×100mm. The surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com