Direct-current switch cabinet and channel steel connection insulation technology in metro traction substation

A technology for traction substations and DC switches, applied in substation/switch layout details, switchgear, substation/distribution device shells, etc., can solve the problems of frame voltage leakage, dust accumulation, and poor sealing of bolt holes, etc., to achieve Guarantee the construction quality, improve the process method, and improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

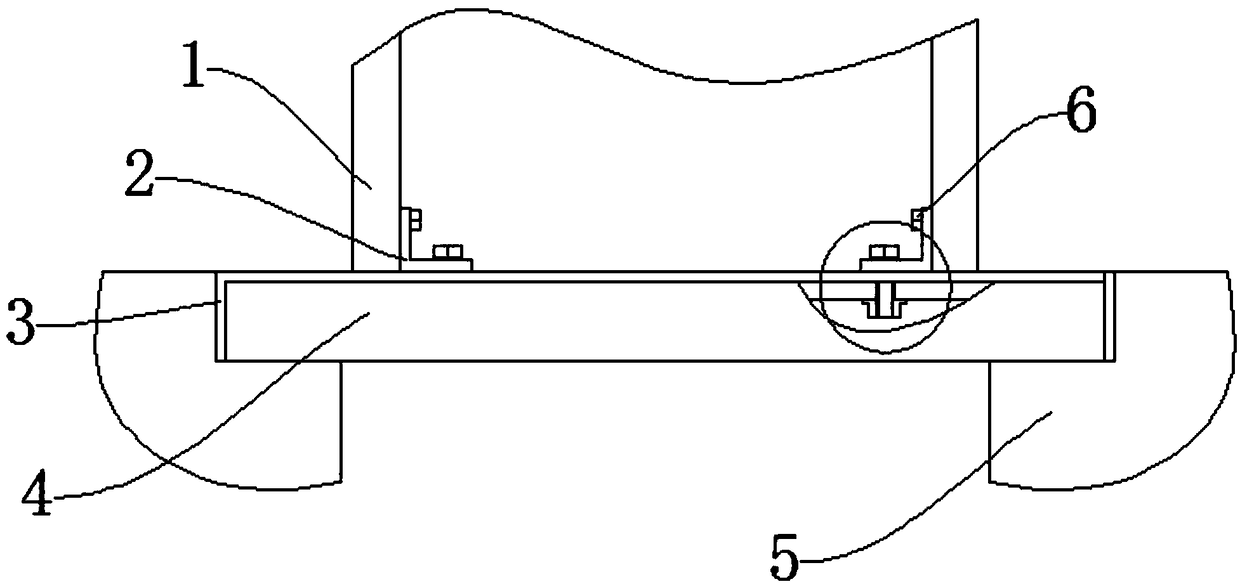

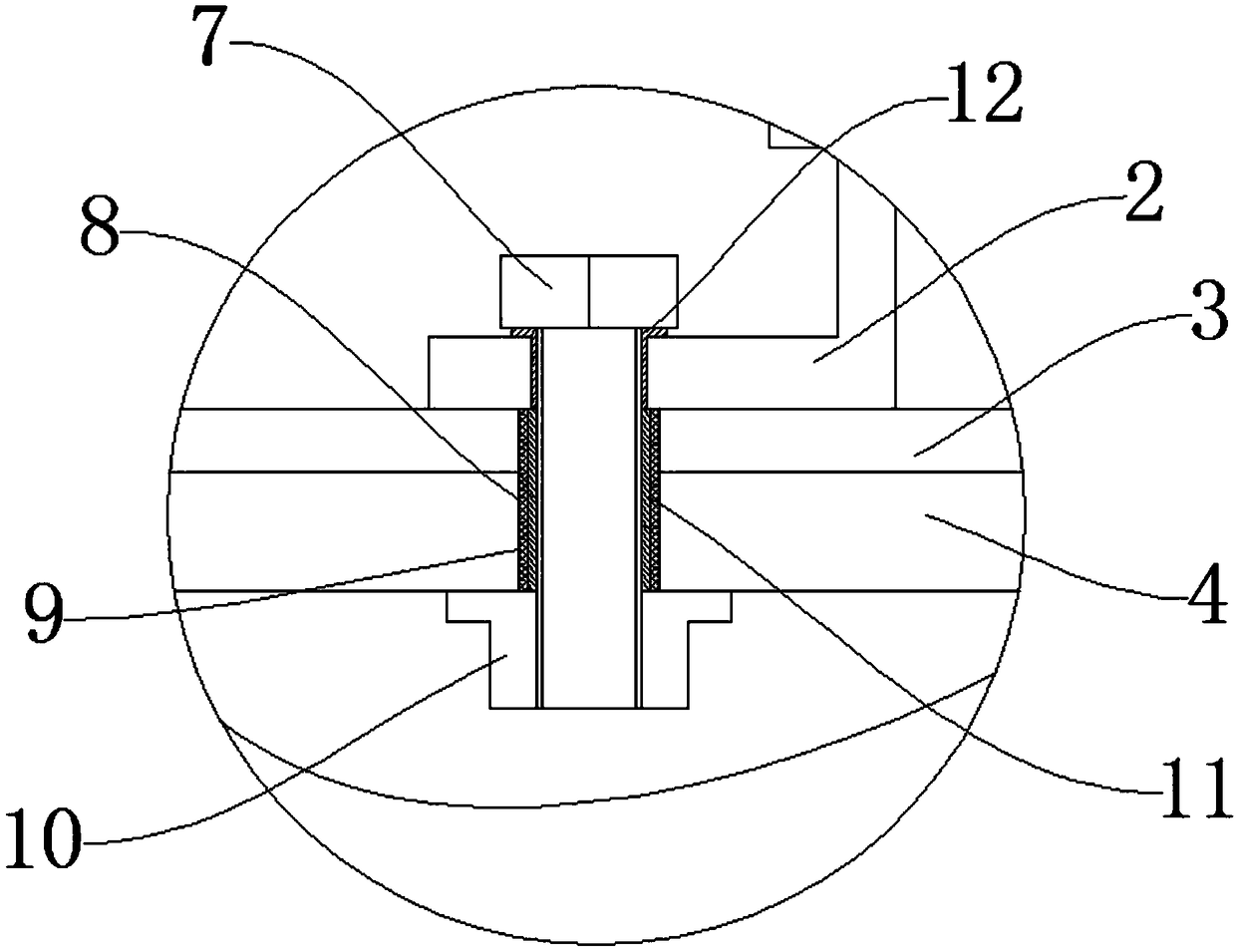

[0020] Such as Figure 1-Figure 2 As shown, the DC switchgear and channel steel connection insulation technology in the subway traction substation includes a basic channel steel 5 and a switch cabinet body 1. An insulating plate 4 is arranged on the basic channel steel 5, and an insulating plate 4 is arranged above the insulating plate 4. There is the switch cabinet body 1, an epoxy resin coating 3 is arranged between the switch cabinet body 1 and the insulating plate 4, and a connecting piece 2 is fixed on the inner side of the lower end of the switch cabinet body 1 through fixing bolts 6, so that The insulating plate 4 is processed with a fixing hole 9, the fixing hole 9 is coated with silicone grease 8, the fixing hole 9 is provided with an insulating bolt 7, and the insulating bolt 7 is provided with an insulating gasket 12 and an insulating sleeve 11. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com