Production device for refractory material adhesive silica sol

A technology for refractory materials and production equipment, applied in the fields of nanotechnology, silicon compounds, inorganic chemistry, etc. for materials and surface science, can solve the problems of complex production equipment, reduce intermediate links in the reaction, improve the reaction yield, reduce Effect of reaction temperature and reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0008] Production raw materials and dosage

Modulus 3.4

5

water

Deionized water

25

Industrial grade, 37%

4

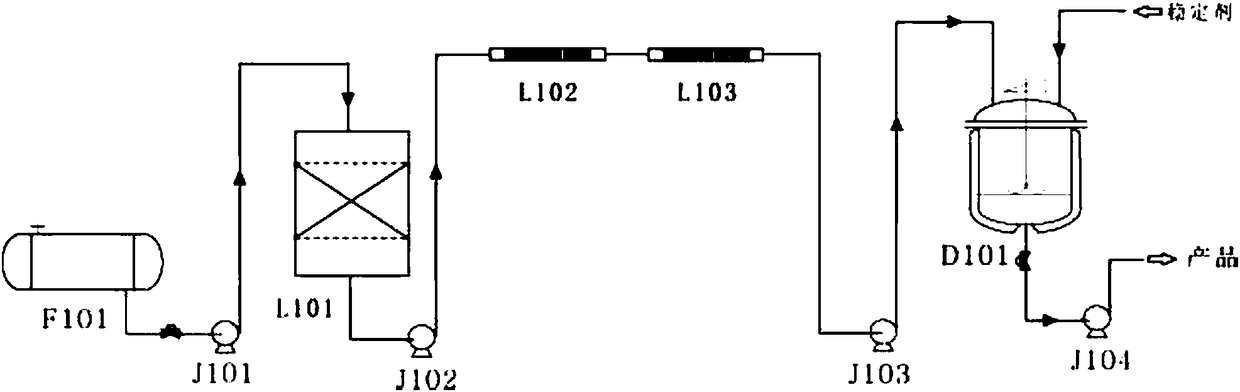

[0010] The production equipment of refractory adhesive silica sol mainly includes: storage tank (F101), raw material pump (J101), filter (L101), delivery pump (J102, J103), cation exchange resin filter (L102), anion Exchange resin filter (L103), growth kettle (D101), product pump (J104), wherein, the storage tank (F101) is used to store the sodium silicate aqueous solution, wherein, the raw material pump (J101) is respectively connected with the storage tank (F101), The filter (L101) is connected, and the transfer pump (J103) is respectively connected with the anion exchange resin filter (L103) and the growth kettle (D101), wherein the storage tank (F101) has a total volume of 2.7m 3 , The diameter of the outlet of the raw material pump (J101) is 210mm, and the diameter ...

example 2

[0015] Production raw materials and dosage

[0016] Sodium silicate

Modulus 3.4

7

water

Deionized water

30

Industrial grade, 37%

6

[0017] The production equipment of refractory adhesive silica sol mainly includes: storage tank (F101), raw material pump (J101), filter (L101), delivery pump (J102, J103), cation exchange resin filter (L102), anion Exchange resin filter (L103), growth kettle (D101), product pump (J104), wherein, the storage tank (F101) is used to store the sodium silicate aqueous solution, wherein, the raw material pump (J101) is respectively connected with the storage tank (F101), The filter (L101) is connected, and the delivery pump (J103) is respectively connected with the anion exchange resin filter (L103) and the growth kettle (D101), wherein the storage tank (F101) has a total volume of 2.9m 3 , The diameter of the outlet of the raw material pump (J101) is 230mm, and the diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com