High-performance combined bulletproof plate

A bullet-proof plate with high performance technology, applied in the field of composite ceramics, can solve the problem of only one-time protection, and achieve the effect of ensuring constant strength, ensuring stability, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

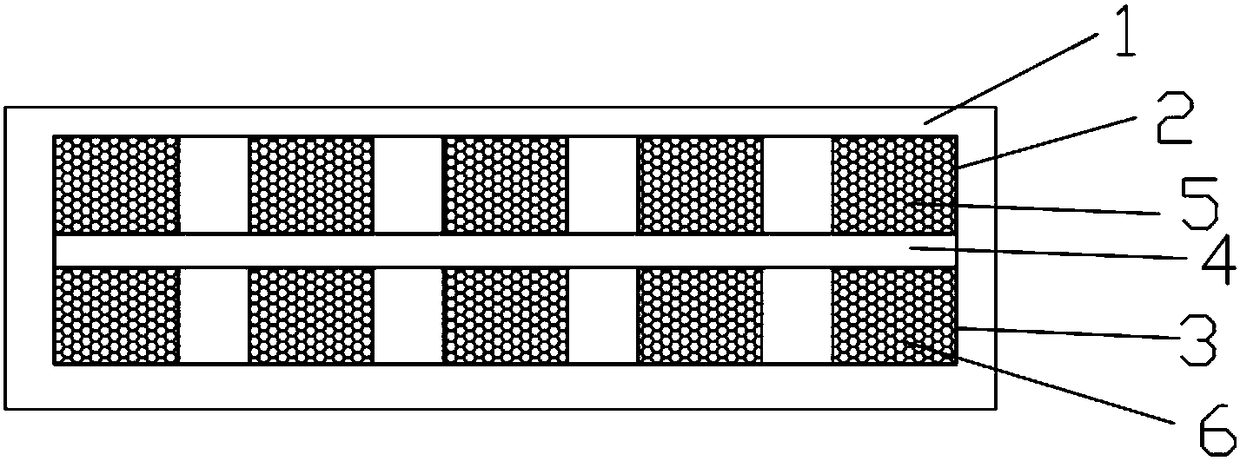

[0027] A high-performance combined bulletproof plate, the bulletproof plate includes a cladding shell 1, a first ceramic baffle 2, a second ceramic baffle 3 and a buffer layer 4, the first ceramic baffle 2 is located on the upper surface of the buffer layer 4 , the second ceramic baffle 3 is located on the lower surface of the buffer layer 4, the first ceramic plate 2 and the second ceramic plate 3 have a honeycomb structure, and the cladding shell 1 combines the first ceramic baffle 2, the second Covered by ceramic baffle 3 and buffer layer 4 .

[0028] The thickness of the first ceramic baffle 2 and the second ceramic baffle 3 is not less than 10-20mm.

[0029] The first ceramic baffle 2 and the second ceramic baffle 3 are made of silicon nitride.

[0030] The covering shell 1 is made of ethylene acrylate elastomer.

[0031] The buffer layer 4 is made of polystyrene-polydimethylsiloxane cross-linked copolymer.

[0032] The diameter of the honeycomb holes of the first cera...

Embodiment 2

[0034] Such as figure 1 As shown, a high-performance combined bulletproof plate, the bulletproof plate includes a cladding shell 1, a first ceramic baffle 2, a second ceramic baffle 3 and a buffer layer 4, and the first ceramic baffle 2 is located in the buffer layer 4 on the upper surface, the second ceramic baffle 3 is located on the lower surface of the buffer layer 4, the first ceramic plate 2 and the second ceramic plate 3 have a honeycomb structure, and the cladding shell 1 covers the first ceramic baffle 2 , The second ceramic baffle plate 3 and the buffer layer 4 are covered.

[0035] The thickness of the first ceramic baffle 2 and the second ceramic baffle 3 is not less than 10-20mm.

[0036] The first ceramic baffle 2 and the second ceramic baffle 3 are made of silicon nitride.

[0037] The covering shell 1 is made of ethylene acrylate elastomer.

[0038] The buffer layer 4 is made of polystyrene-polydimethylsiloxane cross-linked copolymer.

[0039] The honeycomb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com