A kind of special cultivation substrate of Zhejiang shellfish, preparation process and system

A technology of cultivation substrate and preparation process, applied in the directions of planting substrate, medium, application, etc., can solve the problems of low seedling emergence rate of Zhebei shellfish, and achieve the effects of reducing the loss rate of nitrogen, avoiding overacidity, and reducing the rate of miscellaneous bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

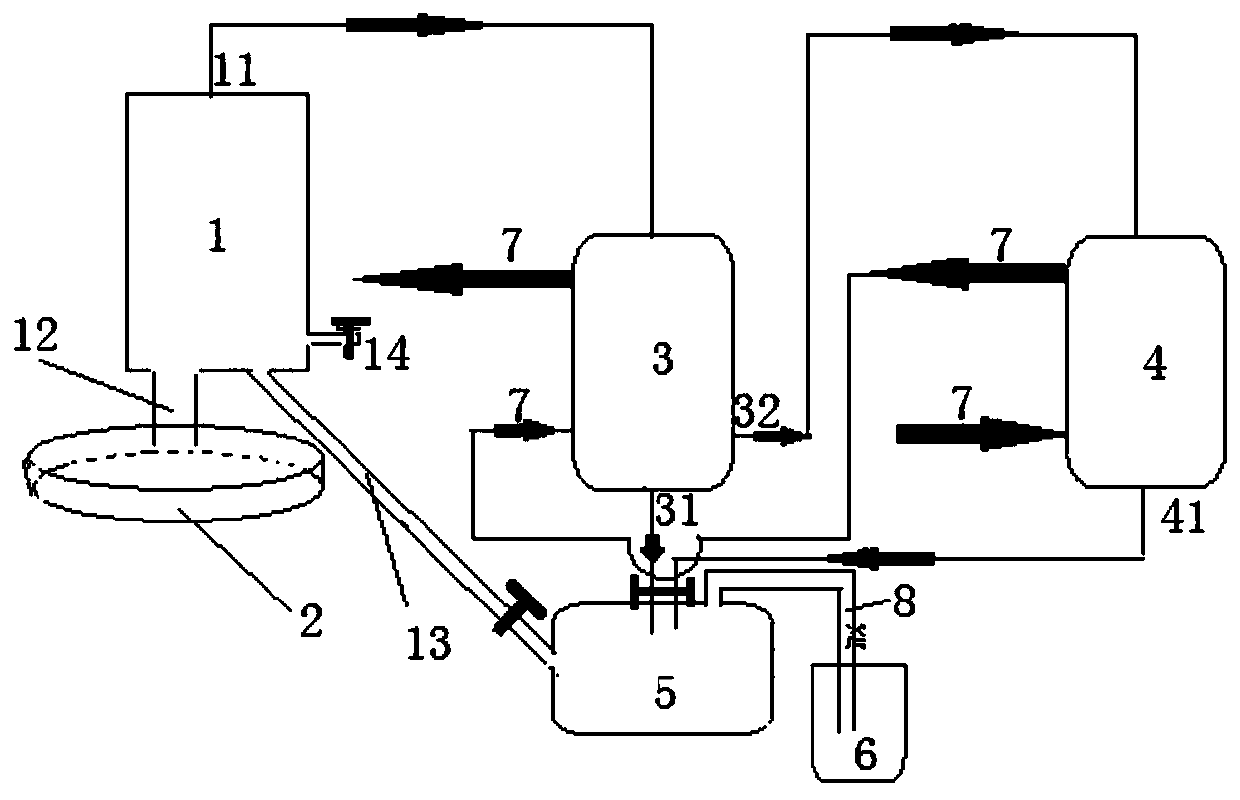

[0044] like figure 1 Shown, a kind of preparation technology of Zhebei special cultivation medium, concrete steps are as follows:

[0045](1) Put the air-dried moso bamboo and cow dung into the carbonization furnace 1 according to the mass ratio of 8:1, connect the gas outlet 11 of the carbonization furnace 1 with the condensing equipment, open the condensing equipment, close the bamboo charcoal discharge port 12 and the activated carbon discharge pipe 13 , heating the material temperature to 250°C at a heating rate of 0.1°C / s, and carbonizing within this temperature range for 15 minutes, the bamboo vinegar vapor generated flows through the condensing equipment to condense into crude bamboo vinegar liquid, and is discharged through the bottom of the condensing equipment To distillation unit 5;

[0046] (2) Continue to heat the material temperature to 300°C, open the bamboo charcoal discharge port 12, use the receiving plate 2 to collect the discharged bamboo charcoal, and spr...

Embodiment 2

[0071] like figure 1 Shown, a kind of preparation technology of Zhebei special cultivation medium, concrete steps are as follows:

[0072] (1) Put the air-dried moso bamboo and cow dung into the carbonization furnace 1 according to the mass ratio of 8:1, connect the gas outlet 11 of the carbonization furnace 1 with the condensing equipment, open the condensing equipment, close the bamboo charcoal discharge port 12 and the activated carbon discharge pipe 13 , heating the material temperature to 350°C at a heating rate of 0.1°C / s, and carbonizing within this temperature range for 20 minutes, the bamboo vinegar vapor generated flows through the condensing equipment to condense into crude bamboo vinegar liquid, and is discharged through the bottom of the condensing equipment To distillation unit 5;

[0073] (2) Continue to heat the material temperature to 350°C, open the bamboo charcoal discharge port 12, use the receiving plate 2 to collect the discharged bamboo charcoal, and sp...

Embodiment 3

[0098] like figure 1Shown, a kind of preparation technology of Zhebei special cultivation medium, concrete steps are as follows:

[0099] (1) Put the air-dried moso bamboo and cow dung into the carbonization furnace 1 according to the mass ratio of 8:1, connect the gas outlet 11 of the carbonization furnace 1 with the condensing equipment, open the condensing equipment, close the bamboo charcoal discharge port 12 and the activated carbon discharge pipe 13 , heating the material temperature to 300°C at a heating rate of 0.1°C / s, and carbonizing in this temperature range for 18 minutes, the bamboo vinegar vapor generated flows through the condensing equipment to condense into crude bamboo vinegar liquid, and is discharged through the bottom of the condensing equipment To distillation unit 5;

[0100] (2) Continue heating the material temperature to 320°C, open the bamboo charcoal discharge port 12, use the receiving tray 2 to collect the discharged bamboo charcoal, and spread i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com