Metal nano porous structure and preparation method and application thereof

A porous structure and nanoporous technology, applied in the field of nanopores, can solve the problems of high production cost and cumbersome process, and achieve the effects of simple materials, mutual conversion, and stable device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

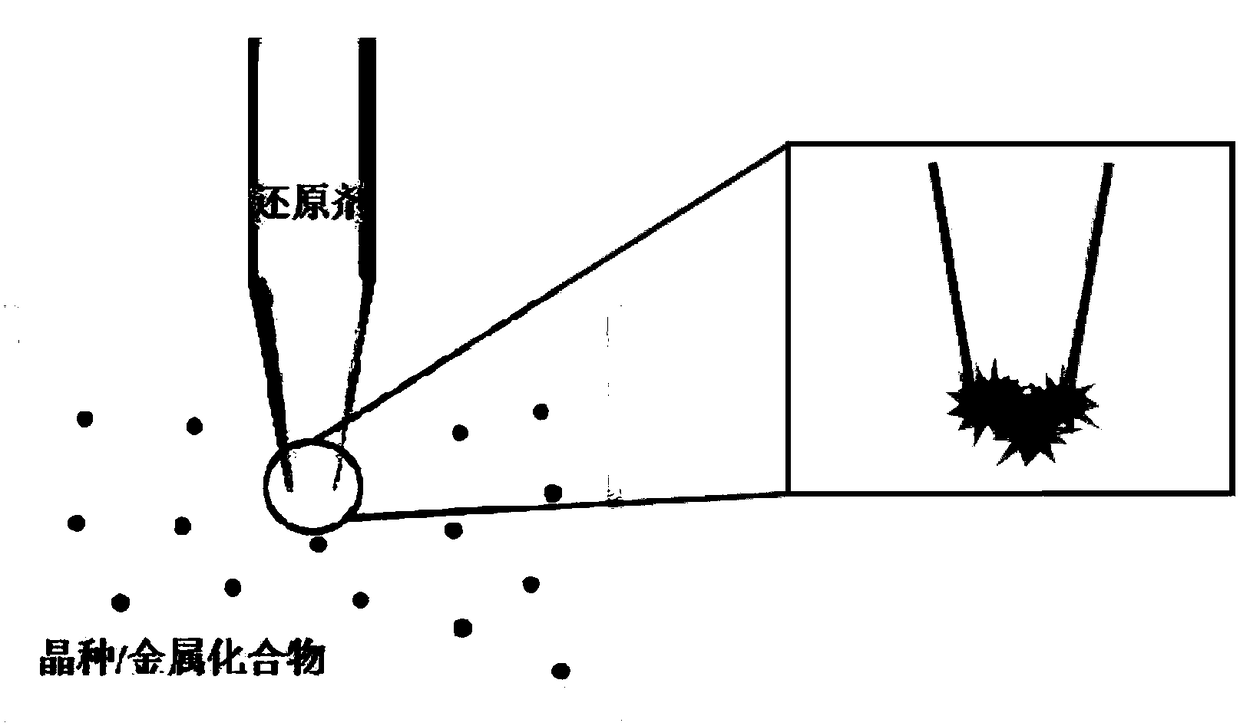

[0044] The method for preparing nanoporous of the present invention, comprises the steps:

[0045] (1) Preparation of glass capillary tip: The instrument used is P-2000 needle puller from SUTTER, USA, and the glass capillary is BOROSILIGATE GLASS WITH FILAMENT from SUTTER, O.D: 1.0mm, I.D: 0.58mm, and the total length is 10cm. Set parameters as LINE 1: HEAT=300, FIL=4, VEL=28, DEL=230, PUL=Null LINE 2: HEAT=290, FIL=3, VEL=25, DEL=200, PUL=170.

[0046] The diameter of the tip of the capillary prepared under the above conditions with this specification capillary is 100-200 nm, such as figure 2 shown.

[0047] (2) Preparation of 15-nm spherical gold nanoparticles seed crystals: 50mL of 0.01% HAuCl 4 Heat the solution to boiling, quickly add 2mL 1% trisodium citrate aqueous solution, some blue at first, then light blue, then blue, then red after heating, and transparent wine red after boiling for 7-10min, stop heating, cool to room temperature Can. The prepared gold nanopar...

Embodiment 2

[0052] Compared with Example 1, Example 2 only prolongs the reaction time in step (5) of Example 1 to 22 h and 30 d respectively, and the overall size and diameter of the prepared metal nanoporous structure are 10 μm and 90 μm, respectively, as Figure 4 c, 4d shown.

Embodiment 3

[0054] Example 3 Compared with Example 1, only the metal nanoporous structure was prepared by directly reacting the chloroauric acid solution in the step (4) of Example 1 without adding a seed crystal. Compared with the seed crystal, the morphology of the metal nanopore formed without the seed crystal is relatively loose, such as Figure 5 As shown, the overall size diameter of the prepared metal nanoporous structure is 3-10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com