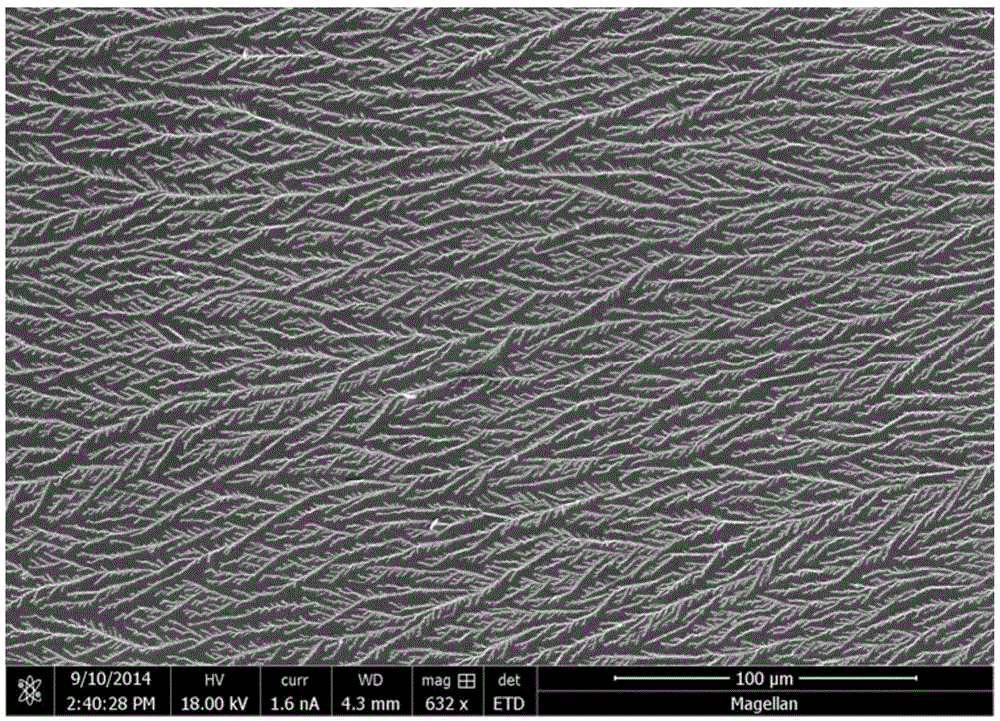

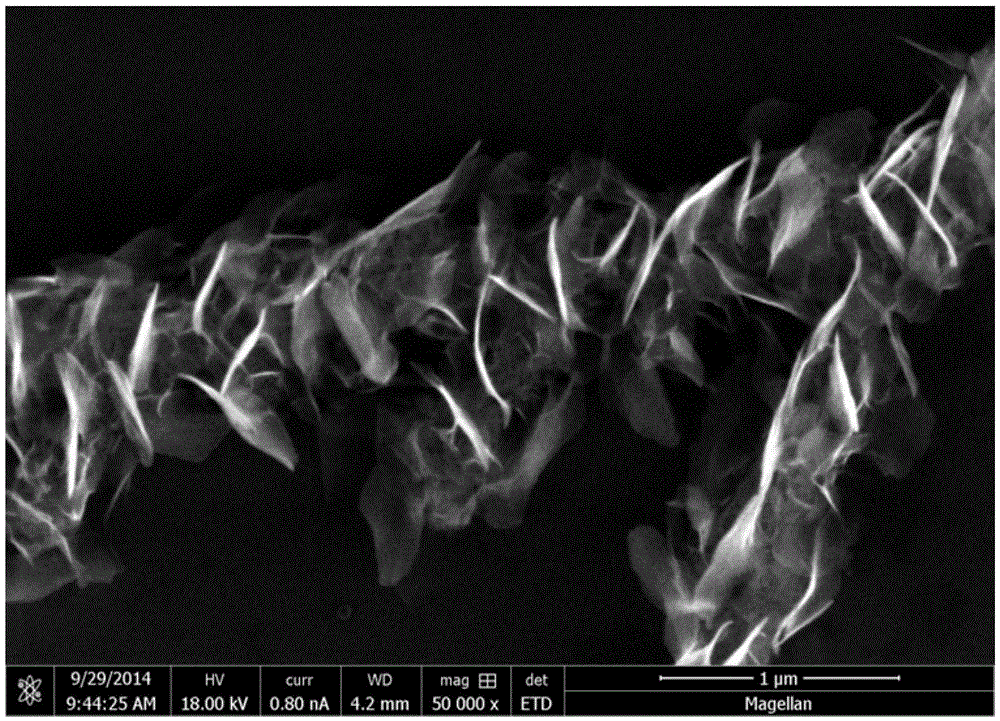

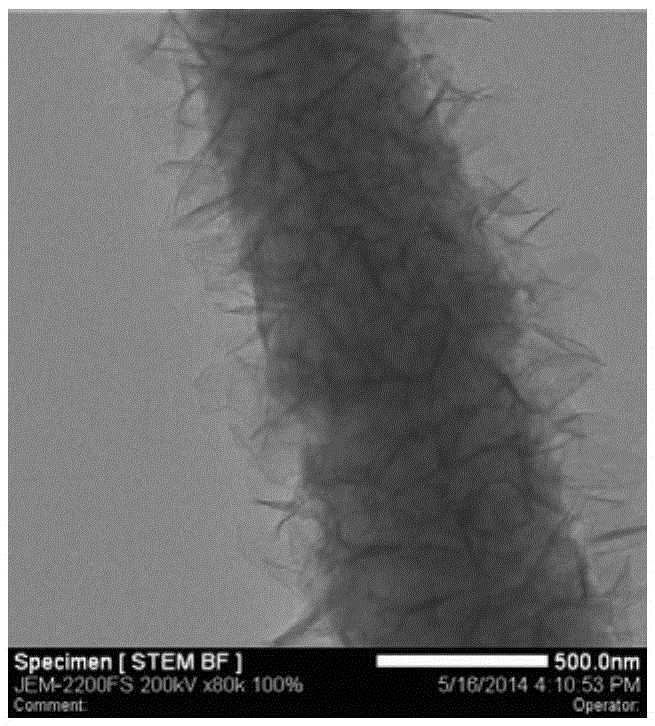

A kind of preparation method of au modified zn/zno micro-nano material

A micro-nano, thermoelectric refrigerator technology, applied in nanotechnology, nanotechnology, material excitation analysis, etc., can solve the problems of low economic efficiency, inconvenient operation, difficult control, etc., and achieve high surface-enhanced Raman activity and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Use deionized water and configure ZnSO with a concentration of 20mM 4 electrolyte.

[0031] (2) Put the silicon wafer on the TEC in the heat preservation room. The TEC model is TEC1-12705. The heat preservation room is connected to a circulating water bath. On the chip, the interval is 0.8cm. Drop ZnSO between the electrodes 4 Electrolyte, cover with a glass slide.

[0032] (3) Adjust the voltage across the TEC to 3V to freeze the electrolyte quickly, and then adjust the voltage across the TEC to -0.3V to slowly melt the electrolyte. Use an optical microscope to observe the dissolution of the ice layer. When the ice layer is only left For ice nuclei with a diameter of about 0.1 mm, disconnect the voltage at both ends of the TEC, and the ice nuclei will gradually become larger until they fill the space between the two electrodes, and then placed for 30 minutes.

[0033] (4) Apply a DC voltage of 0.8V across the electrodes and deposit for 30 minutes.

[0034] (5)...

Embodiment 2

[0038] (1) Use deionized water and configure ZnSO with a concentration of 50mM 4 electrolyte.

[0039] (2) Put the silicon wafer on the TEC in the heat preservation room. The TEC model is TEC1-12705. The heat preservation room is connected to a circulating water bath. On the chip, the interval is 0.8cm. Drop ZnSO between the electrodes 4 Electrolyte, cover with a glass slide.

[0040](3) Adjust the voltage across the TEC to 3V to freeze the electrolyte quickly, and then adjust the voltage across the TEC to -0.3V to slowly melt the electrolyte. Use an optical microscope to observe the dissolution of the ice layer. When the ice layer is only left For ice nuclei with a diameter of about 0.1 mm, disconnect the voltage at both ends of the TEC, and the ice nuclei will gradually become larger until they fill the space between the two electrodes, and then placed for 30 minutes.

[0041] (4) Apply a DC voltage of 1.4V across the electrodes and deposit for 30 minutes.

[0042] (5) ...

Embodiment 3

[0047] (1) Use deionized water and configure ZnSO with a concentration of 80mM 4 electrolyte.

[0048] (2) Put the silicon wafer on the TEC in the heat preservation room. The TEC model is TEC1-12705. The heat preservation room is connected to a circulating water bath. On the chip, the interval is 0.8cm. Drop ZnSO between the electrodes 4 Electrolyte, cover with a glass slide.

[0049] (3) Adjust the voltage across the TEC to 3V to freeze the electrolyte quickly, and then adjust the voltage across the TEC to -0.3V to slowly melt the electrolyte. Use an optical microscope to observe the dissolution of the ice layer. When the ice layer is only left For ice nuclei with a diameter of about 0.1 mm, disconnect the voltage at both ends of the TEC, and the ice nuclei will gradually become larger until they fill the space between the two electrodes, and then placed for 30 minutes.

[0050] (4) Apply a DC voltage of 1.0V across the electrodes and deposit for 30 minutes.

[0051] (5)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com