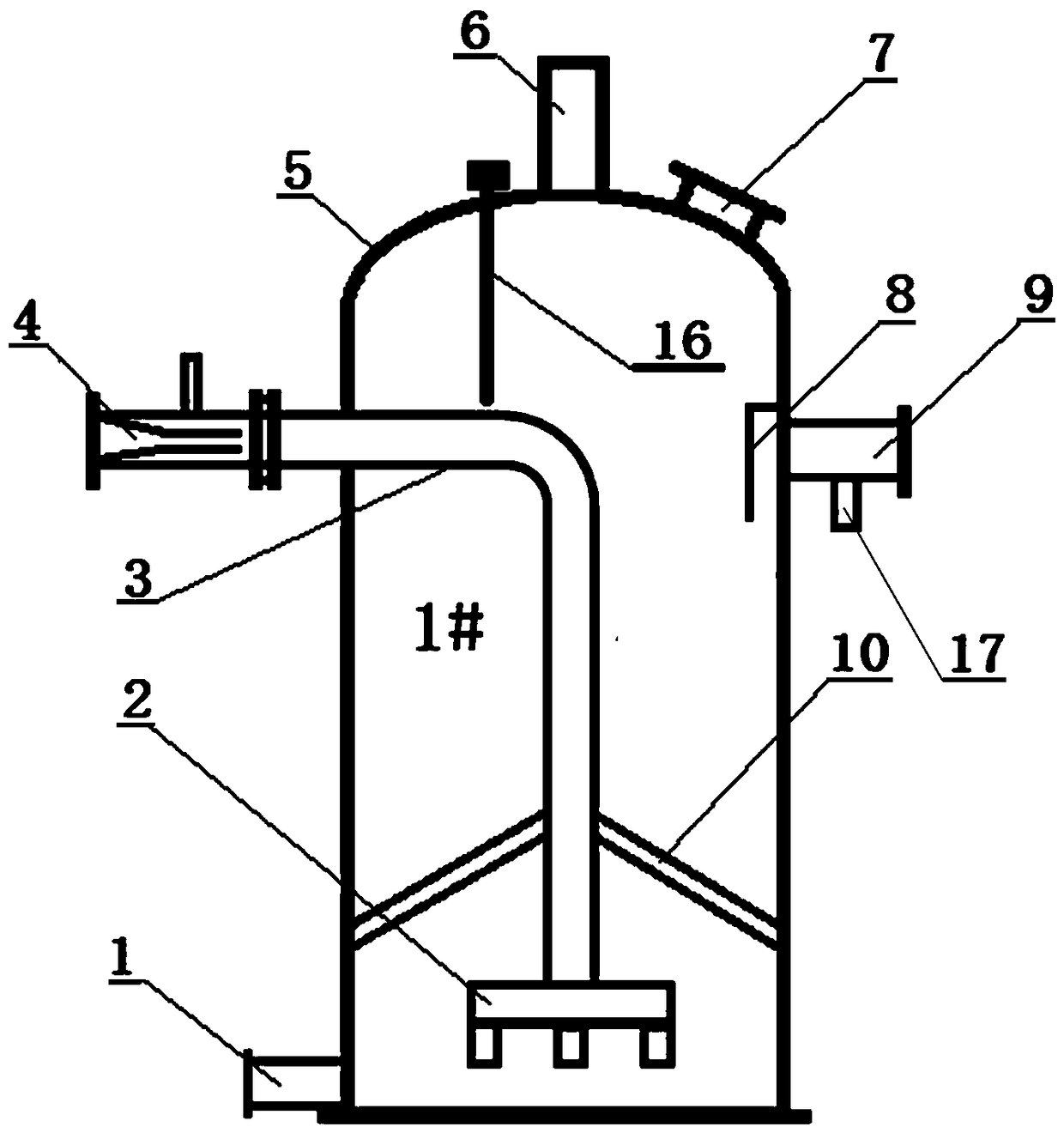

Cyanide breaking device for cyanide-containing tailings and use method of cyanide breaking device

A tailings and cyanide breaking technology, applied in chemical instruments and methods, mining wastewater treatment, water pollutants, etc., can solve the problems of highly toxic cyanide entering the groundwater system, threatening the lives of surrounding humans and animals, and the danger of poisoning the surrounding environment. Achieve the effects of quick and convenient adjustment of equipment parameters, simple structure and reliable operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

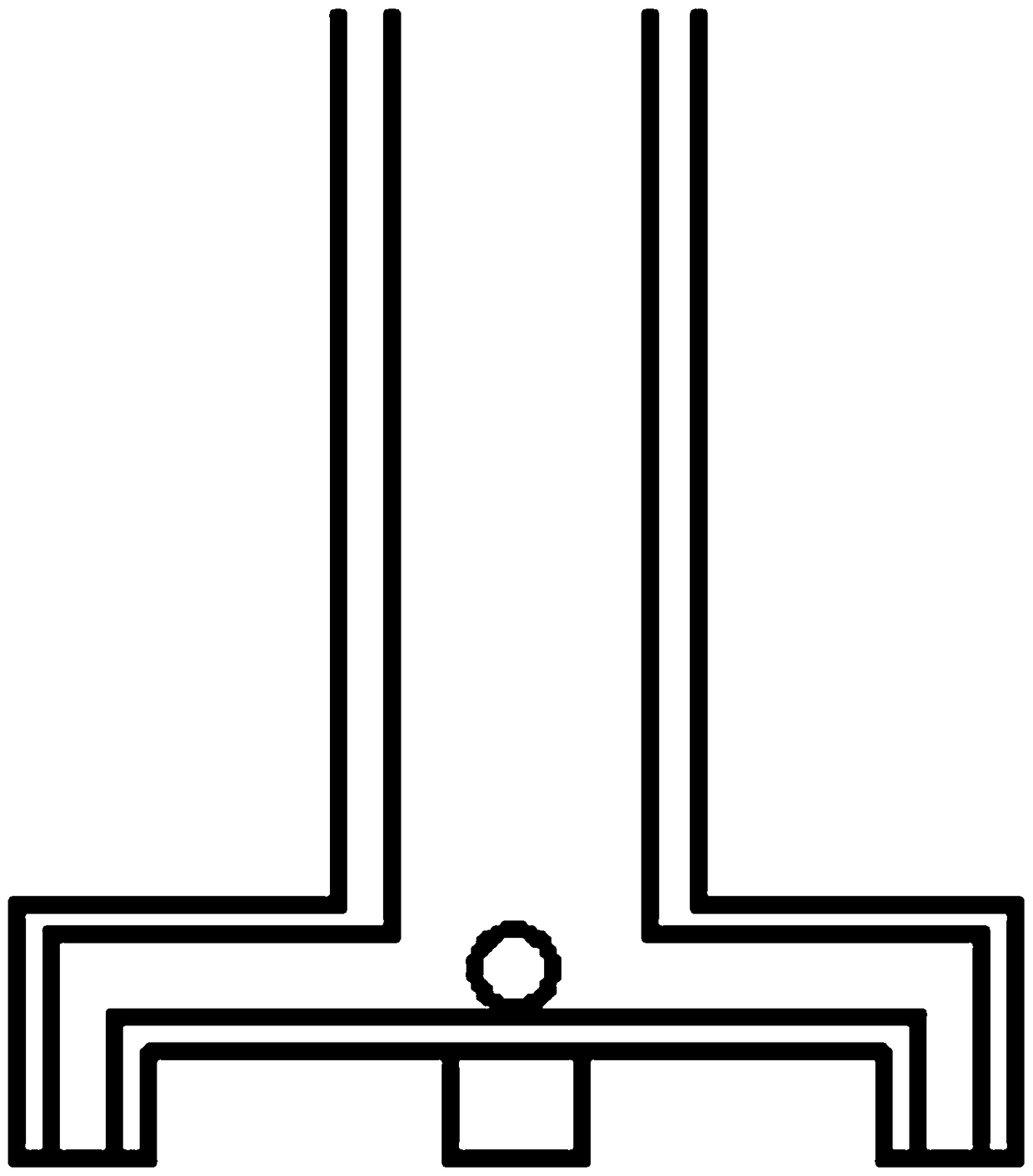

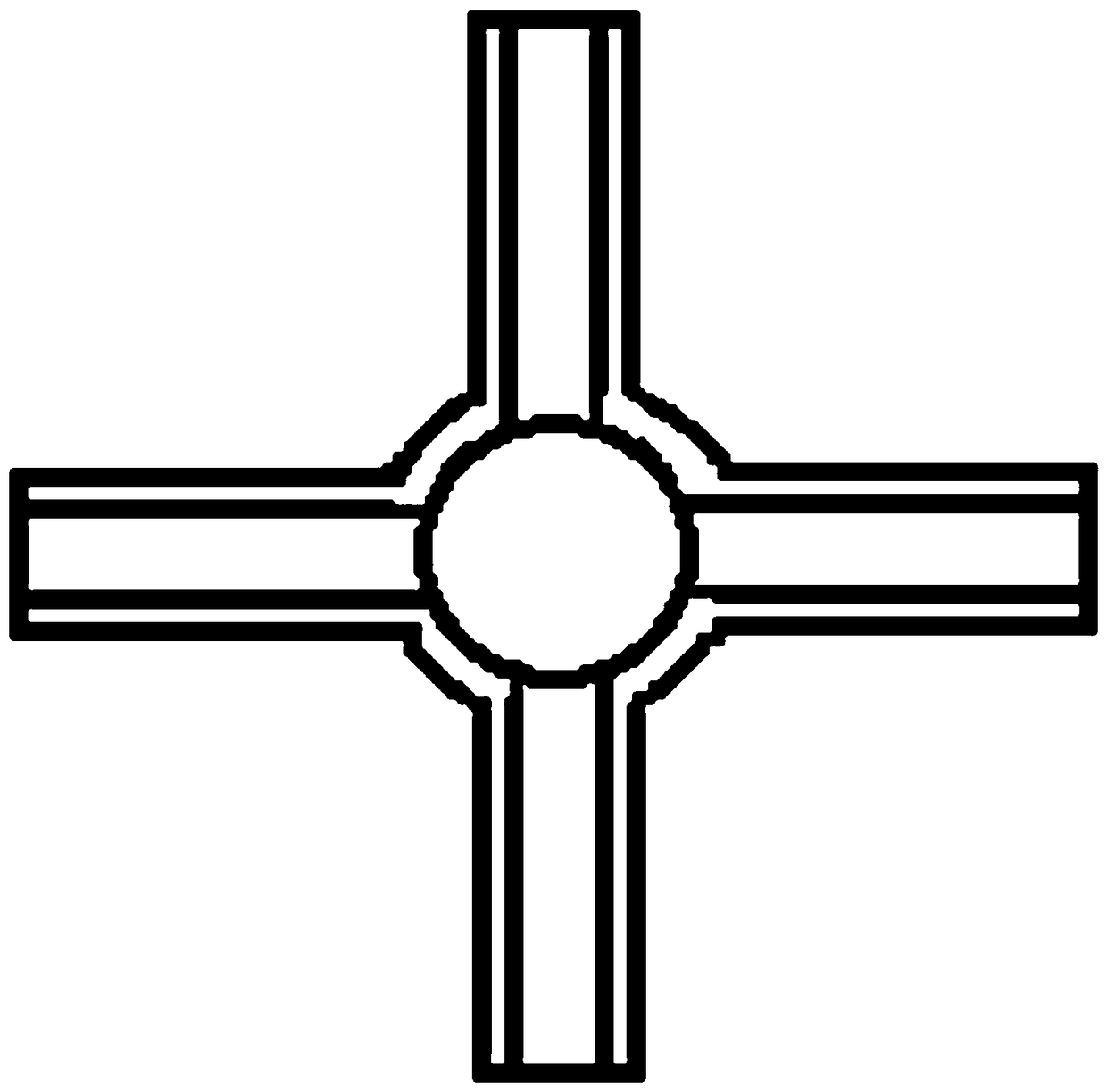

Method used

Image

Examples

Embodiment 1

[0050] For the cyanide breaking device and process method of cyanide-containing tailings pulp of the present invention, we have carried out small-scale tests of multiple embodiments by using a small-scale laboratory device. The samples of the small-scale tests are from the tailings produced by the gold enterprise's full mud cyanide carbon pulp factory. After adding water and cyanide, it is adjusted to the required concentration; a small aeration tower is used (the effective volume of a single tower is 30L), the sand pump is replaced by a micro water pump, and the model of the ozone generator is NLO-500 (oxygen source, power 4KW, maximum o 3 Output 600g / h). The experimental index parameters obtained in the embodiment are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com