Large-slenderness-ratio orbit-control lateral jet-flow force test structure

A large slenderness ratio and orbit control technology, applied in the field of wind tunnel experiments, can solve the problems of reducing the structural design difficulty of other components, the circumferential change of the nozzle layout, and the easy disassembly of the roll angle transformation model, so as to save cost and time, Realize the effect of variable roll angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

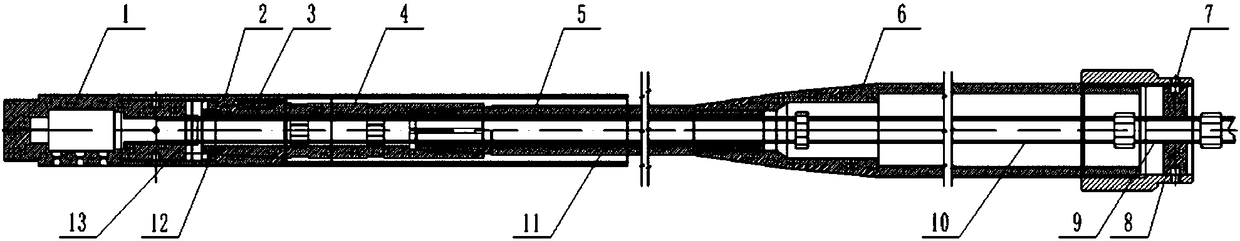

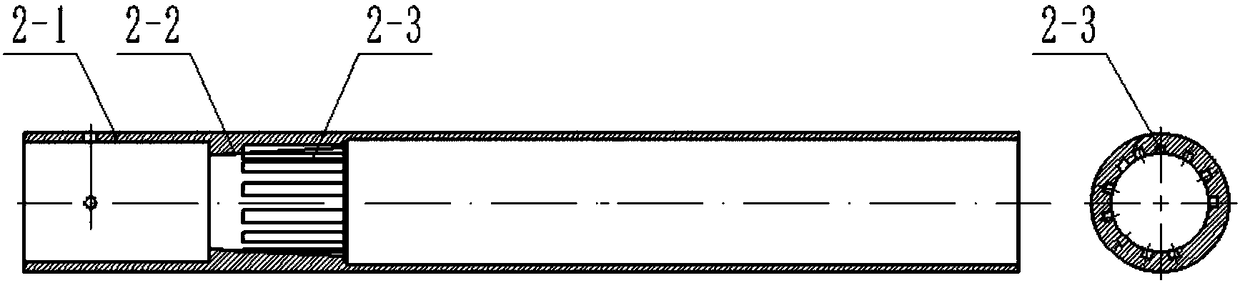

[0037] The present invention is used for a large slenderness ratio and large flow rail-controlled lateral jet force measurement test structure, such asfigure 1 As shown, it includes spout block 1, model main body 2, positioning key 3, five-component balance element 4, support system (support system front section 5, support system rear section 6, fixing nut 7, pipe end fixing clamp 8, fixing Transfer rigid air supply pipeline 9, non-metallic hose 10, inner rigid air supply pipeline 11, balance outer lock nut 12, O-ring 13;

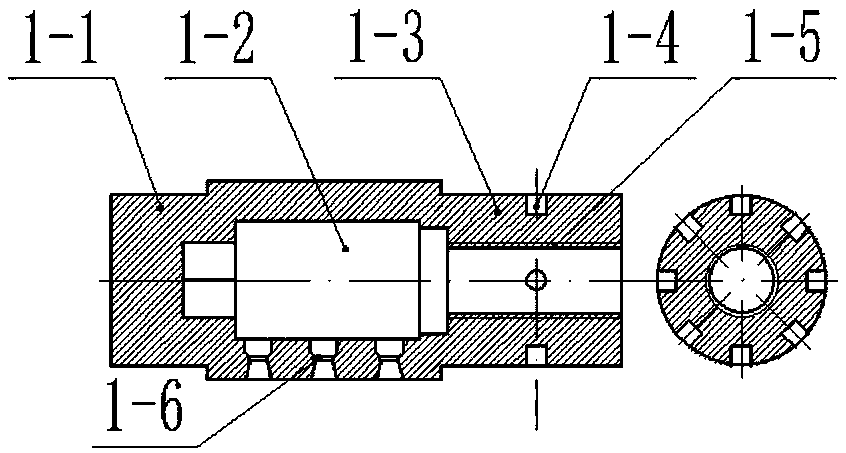

[0038] Such as image 3 As shown, the nozzle block 1 is a columnar structure, including the front-end connection structure 1-1, the resident chamber 1-2, the rear-end connection structure 1-3, the circumferential positioning pin holes 1-4, and the nozzle block gas inlet 1. -5 and nozzles 1-6; the front connection structure is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com