High-performance concrete preparation method

A kind of high-performance concrete and concrete technology, applied in the direction of instruments, electrical digital data processing, special data processing applications, etc., to achieve the effect of protecting land, protecting the environment, and reducing the pressure of environmental damage and self-purification cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

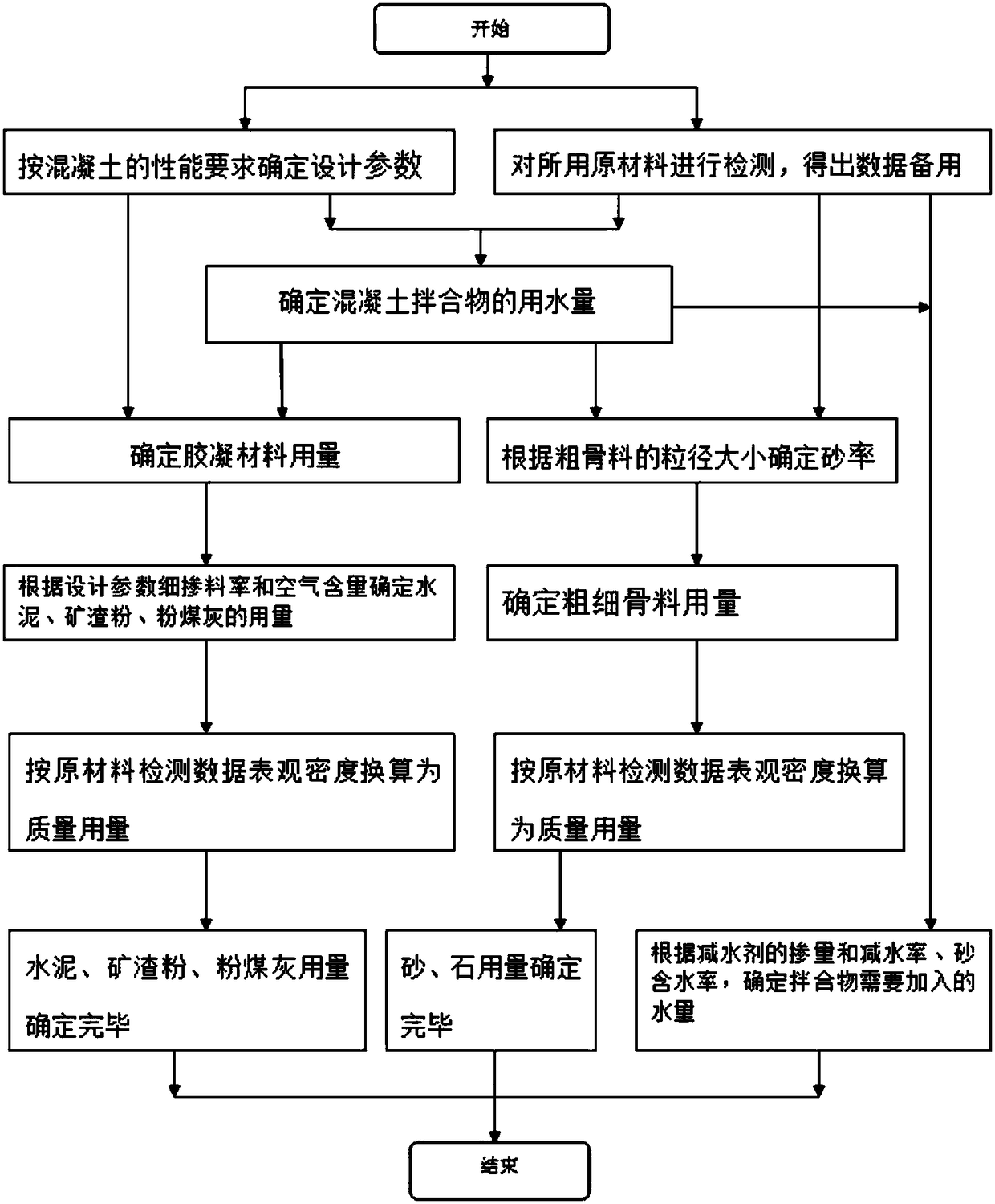

Method used

Image

Examples

Embodiment Construction

[0068] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

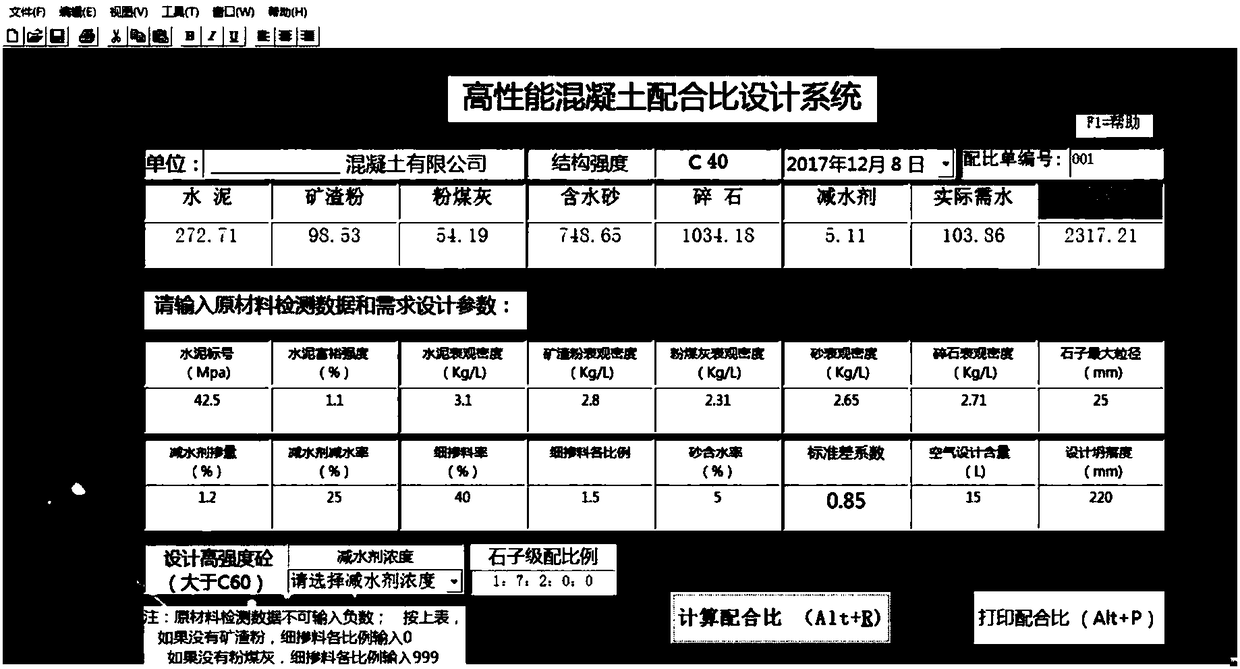

[0069] For the method of the present invention, the applicant has developed auxiliary design software, and the present invention is described in detail below first in conjunction with software design, and the variables in the formula are defined as follows in the following content:

[0070] Fce: cement grade (32.5 / 42.4 / 52.5 / 62.5)

[0071] C: Amount of cement

[0072] K: Amount of slag powder

[0073] F: The amount of fly ash

[0074] S: Amount of anhydrous sand

[0075] Sw: amount of water-containing sand

[0076] G: Amount of gravel

[0077] Jsj: dosage of water reducer

[0078] water: Total water consumption of water-free sand without water reducer

[0079] W: the amount of water that needs to be added to the water-containing sand with the water reducing agent

[0080] peizhiqdu: concrete preparation strength

[0081] concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com