Prediction method of mechanical response characteristics of cemented filling body based on SEM image

A technology of cemented filling and response characteristics, applied in special data processing applications, material analysis by measuring secondary emissions, instruments, etc., can solve problems such as delay in mining construction period, high manpower and material resources, and long test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

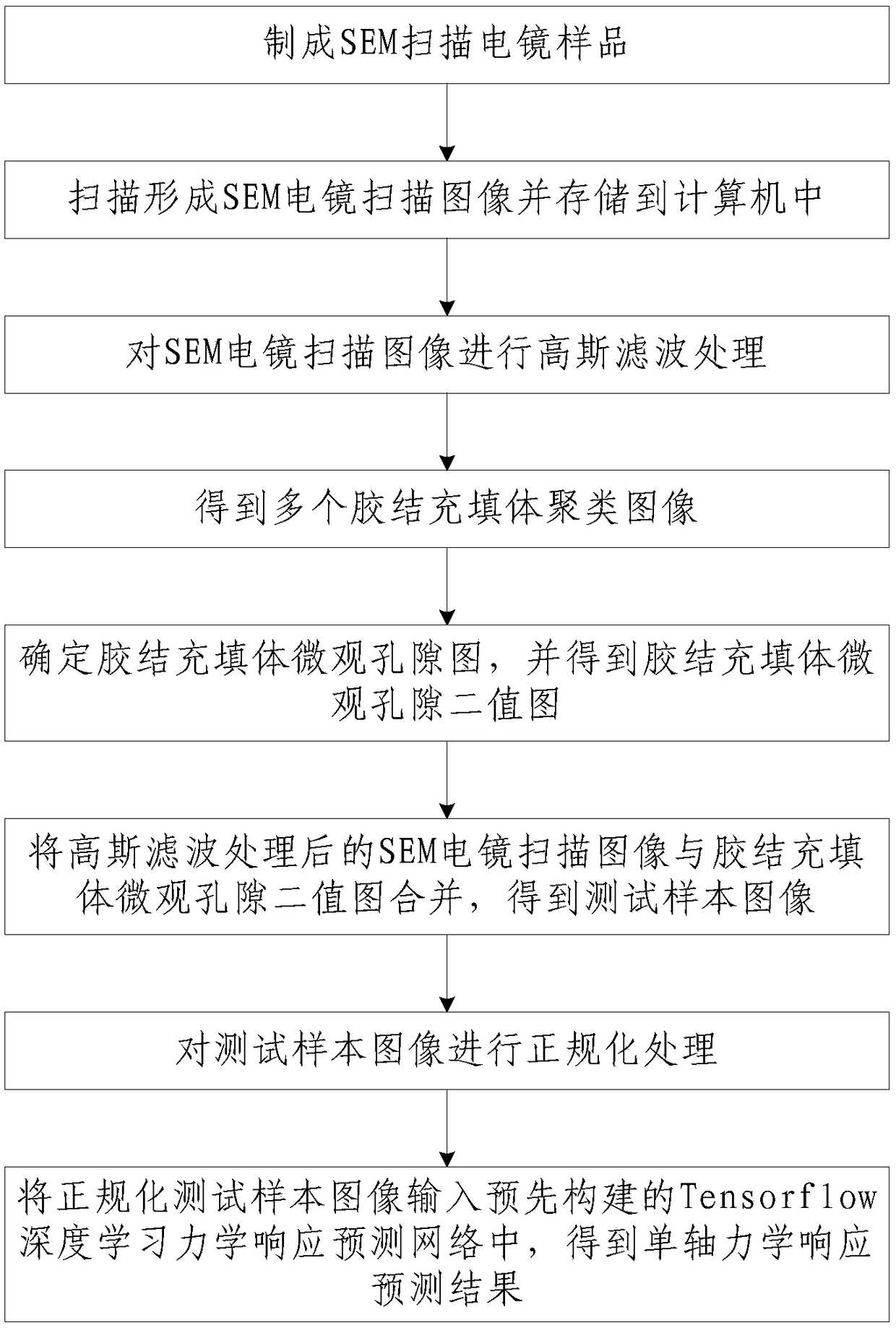

[0069] Such as figure 1 As shown, the method for predicting the mechanical response characteristics of cemented filling bodies based on SEM images of the present invention includes the following steps:

[0070] Step 1, taking a part from the cemented filling body sample 19 to make a SEM scanning electron microscope sample;

[0071] During specific implementation, the SEM scanning electron microscope sample was also subjected to multiple carbon spraying treatments.

[0072] In this embodiment, the length, width and height of the SEM scanning electron microscope sample in step 1 are all 10 mm.

[0073] Step 2, using SEM scanning electron microscope to scan the SEM scanning electron microscope sample, forming a SEM scanning electron microscope scanning image and storing it in the computer 17;

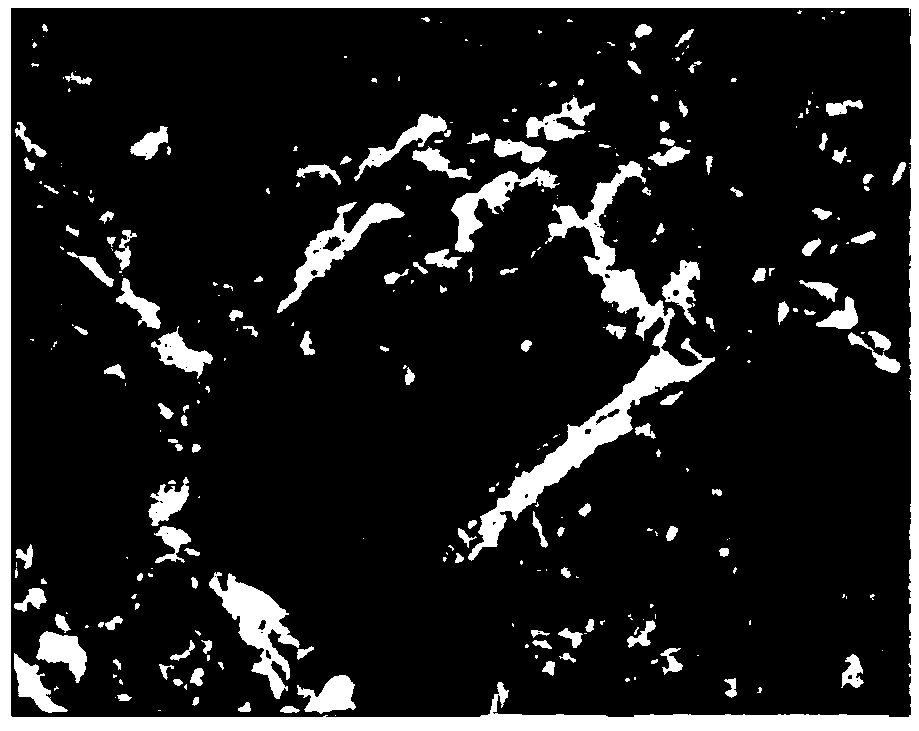

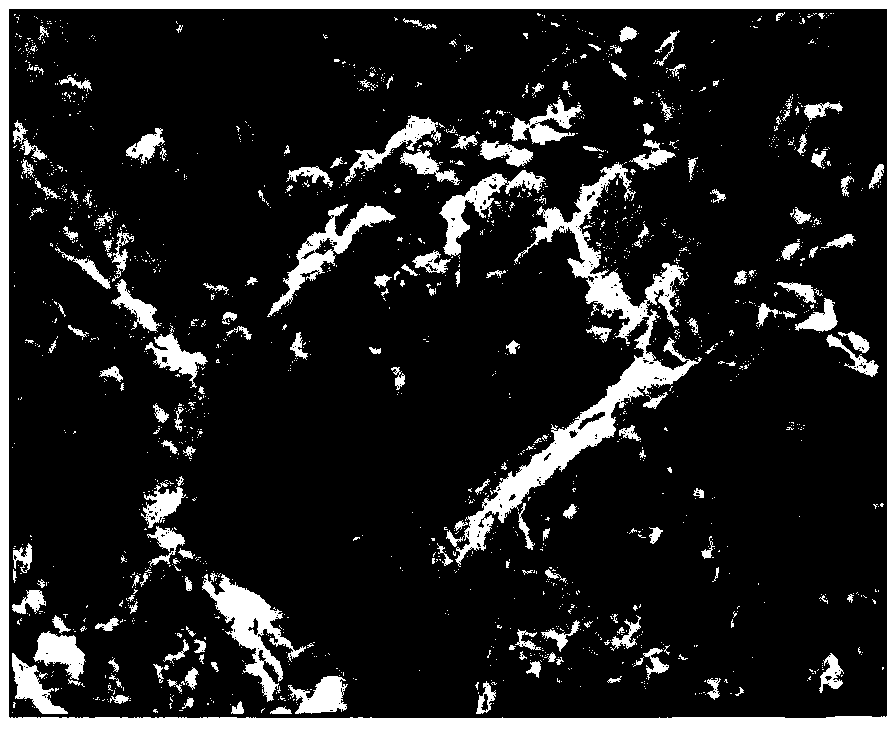

[0074] Step 3, the computer 17 invokes the Gaussian filter processing module to perform Gaussian filter processing on the SEM electron microscope scanned image, and obtains the SEM elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com