Common-type radar antenna cover and winding forming method

A radar radome and winding forming technology, which is applied in the direction of antenna, antenna parts, radiating unit cover, etc., can solve the problem that the rigidity of the radome and the sealing performance of the radome cannot meet the electrical performance requirements at the same time, and achieve product quality consistency High, low density, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

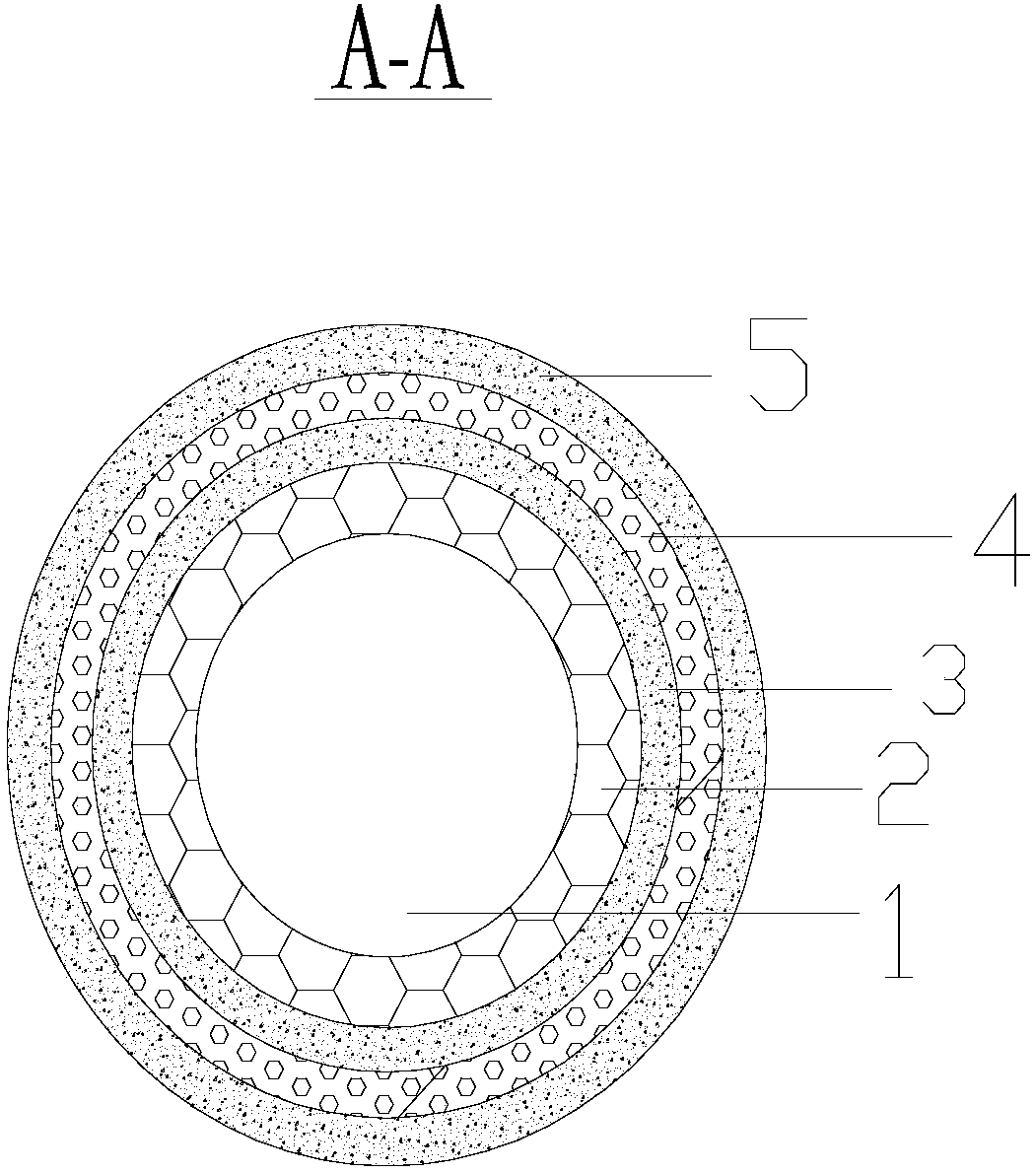

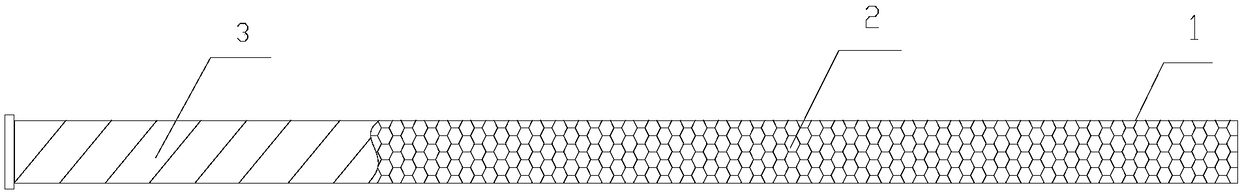

[0043] combined with figure 1 , a kind of common type radar radome of the present invention, comprises the isolation medium 2 that is coated on the antenna array 1 successively from inside to outside, glass fiber glass cloth tape 3, waterproof film 4, glass fiber winding tow 5.

[0044] Wherein the antenna element 1 is a hollow cylindrical structure composed of a cylindrical antenna surface, an inner conductor, an outer conductor, cables and the like;

[0045] Described isolation medium 2 is specifically a kind of NOMEX paper honeycomb with low density and low dielectric loss. Structural transition;

[0046] The glass fiber glass cloth tape 3 is a glass fiber tape with a width of 80mm. The main function is to bind the low-density paper honeycomb on the surface of the antenna array. Wrap and stick to the surface;

[0047] Described waterproof membrane 4, is a kind of low dielectric property, the membranous material of high density, spreads on the glass fiber glass cloth band...

Embodiment 2

[0050] A winding forming method of a common type radome of the present invention comprises the following steps:

[0051] (1) Attach the isolation medium 2 to the antenna element 1;

[0052] (2) Use glass fiber glass cloth tape 3 to bind the isolation medium 2 on the surface of the antenna array 1;

[0053] (3) Brush glue on the fiberglass glass cloth belt 3 and soak;

[0054] (4) Wrap the waterproof membrane 4 on the surface of the glass fiber glass cloth tape 3;

[0055] (5) dipping the glass fiber winding tow 5 into glue and wrapping it on the surface of the waterproof membrane 4 to obtain a conformal body;

[0056] (6) Place the conformal body at room temperature for curing and molding.

Embodiment 3

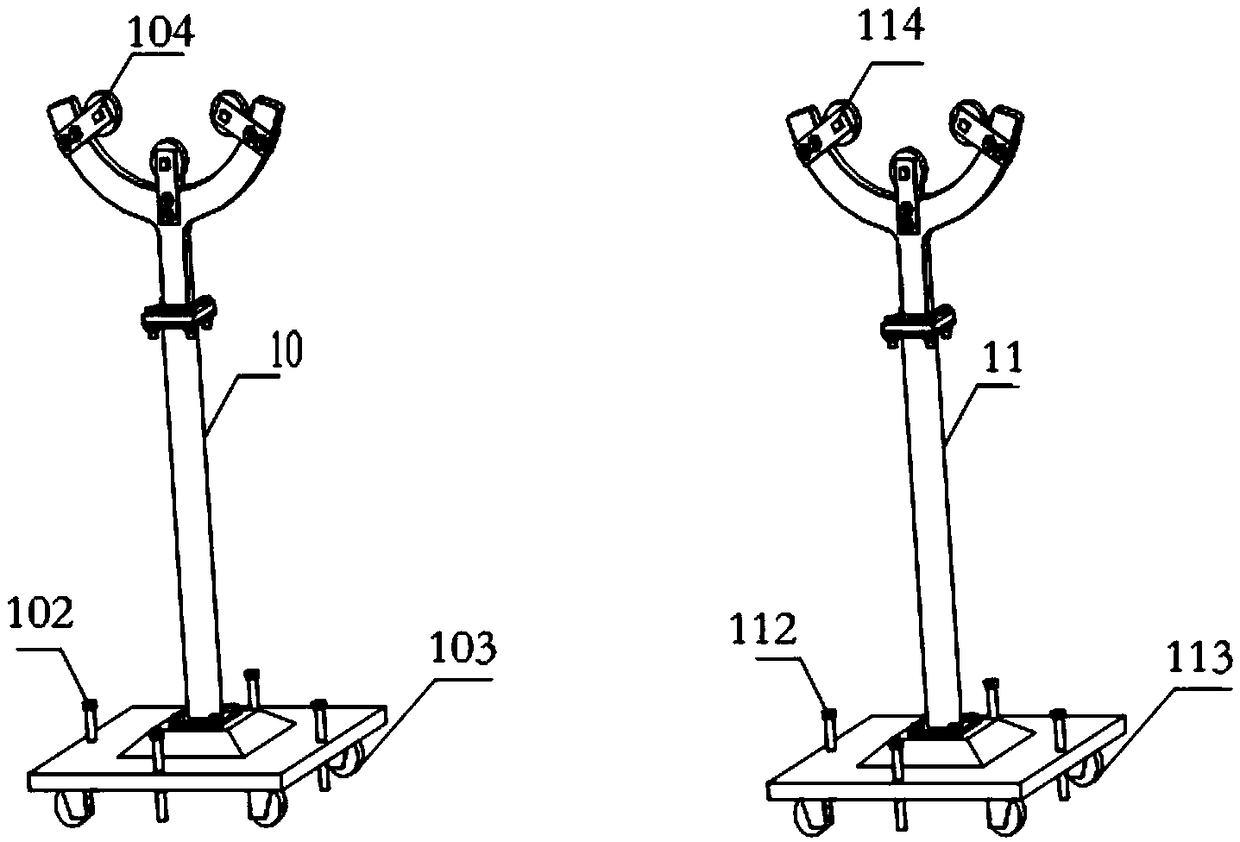

[0058] combined with figure 2 and image 3 , on the basis of Embodiment 2, use a manual winding device, including a pair of brackets 10,11, the bottom of the brackets 10,11 are equipped with universal wheels 13 and bolts 102,103 for fixing the brackets, and the tops are equipped with There are semicircular brackets, and a pair of semicircular brackets are provided with 3 surrounding guide wheels 104, 114; steps (1) and (2) are specifically:

[0059]Adjust the distance between the brackets 10 and 11 to an appropriate distance, which is slightly smaller than the length of the antenna element 1, then fix the bracket, place the two ends of the antenna element 1 on the guide wheels 104 and 114 of the bracket 10 and the bracket 11, and manually rotate The antenna element 1 drives the guide wheels 104, 114 on the bracket, and the isolation medium 2, namely NOMEX paper honeycomb, is bound on the surface of the antenna element 1 with glass fiber glass cloth tape 3 during the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com