Automatic intelligent production line and method for recycling organic waste by biological conversion

A technology of organic waste and biotransformation, applied in solid waste removal, animal husbandry, etc., can solve problems affecting the efficiency of black soldier flies in digesting food waste, and achieve the effect of improving digestion efficiency and rapid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

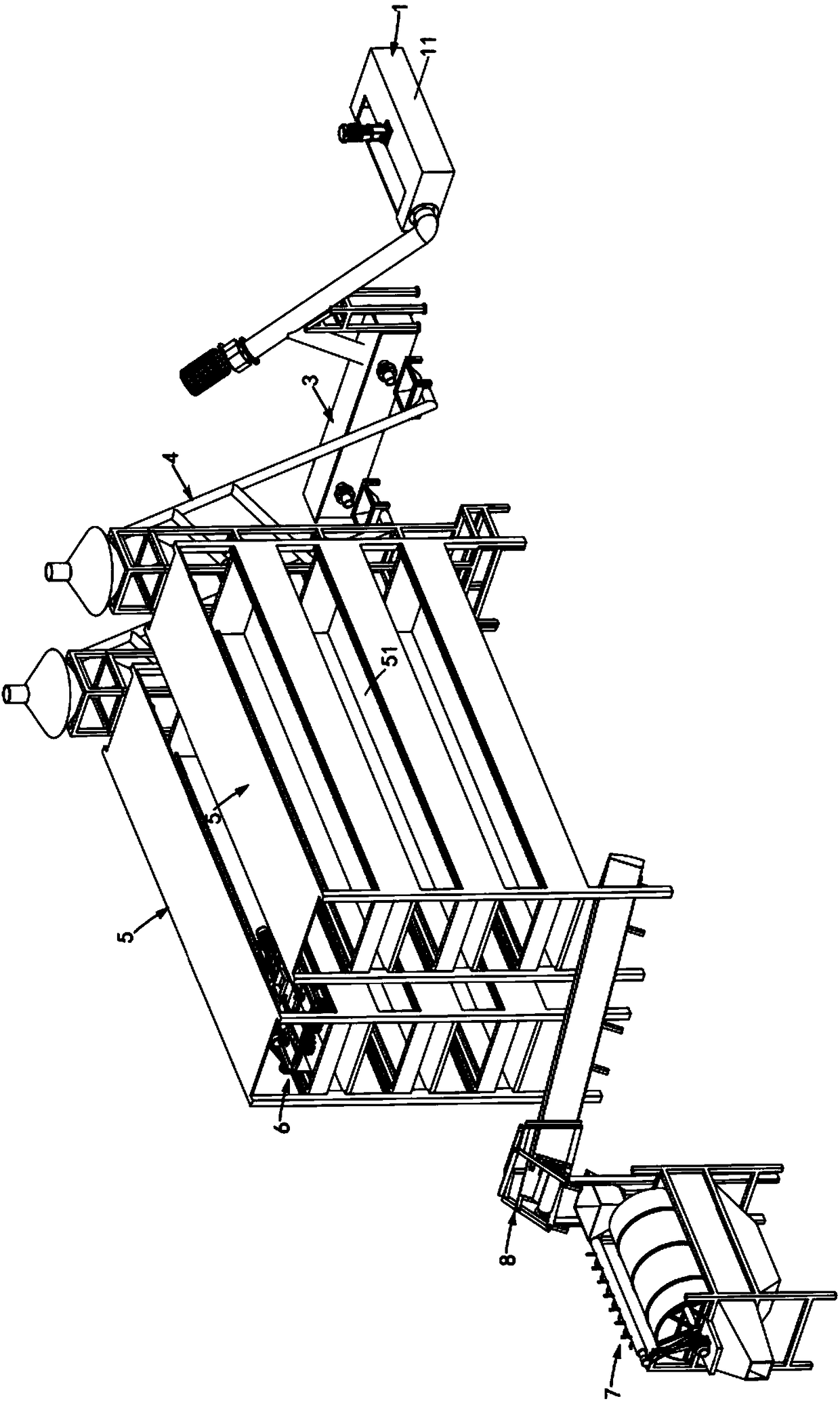

[0078] Such as figure 1 , figure 2 and Figure 5 As shown, the automated intelligent production line utilizing biotransformation of organic waste resources for reuse includes a conditioning and mixing device 1, a lifting device 2, a filtering device 3 and a pumping device 4, and the lifting device 2 is arranged on the conditioning and mixing device 1 On, it communicates with described tempering stirring device 1 and filter device 3 respectively, and pumping device 4 communicates with described filter device 3, also includes:

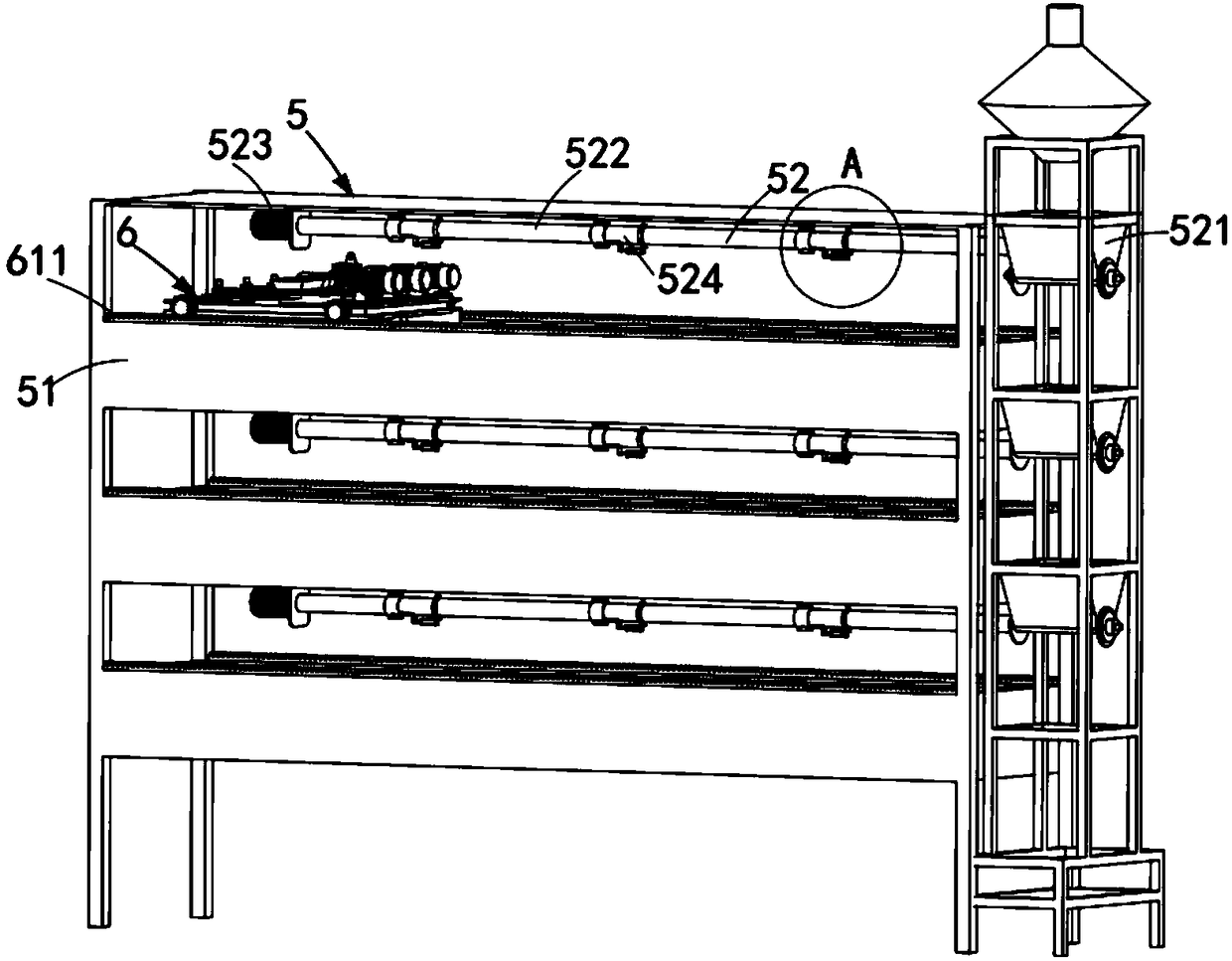

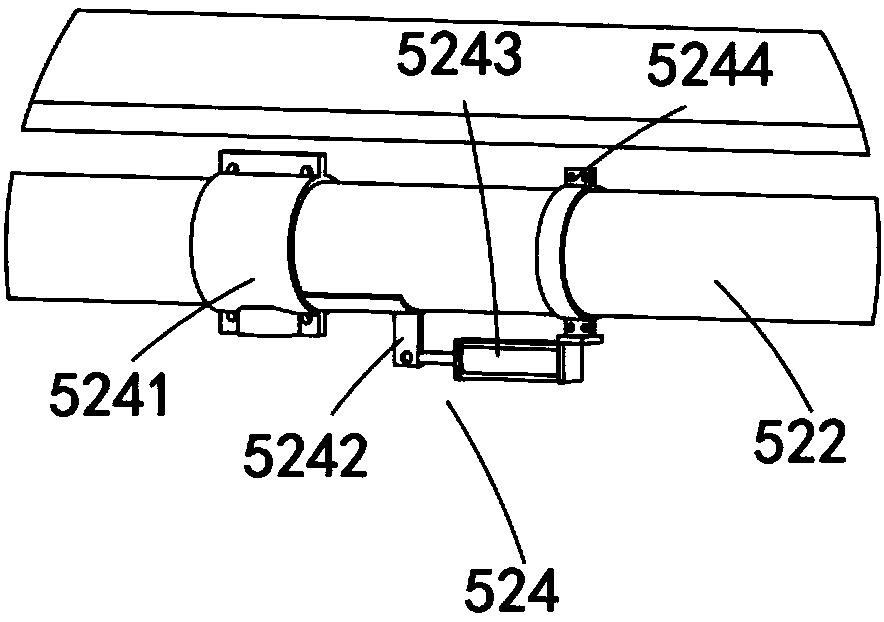

[0079] Biological bed 5, described biological bed 5 is arranged indoors, and it is rectangular setting, and it is arranged on the side of described pumping device 4, and this biological bed 5 is provided with the treatment tank 51 that horizontally places, and this treatment tank 51 A feeding mechanism 52 is arranged above the top, and the feeding mechanism 52 is correspondingly matched with the pumping device 4, and the feeding mechanism 52 is suppli...

Embodiment 2

[0128] Referring to Example 1, the method for reusing organic waste resources by biotransformation of the present invention is described.

[0129] Such as Figure 10 As shown, in step 1, feeding, put the sieved organic waste into the conditioning tank 11 of the conditioning and mixing device 1, and put probiotic enzymes into the conditioning tank 11, and mix it with the conditioning and mixing device 1 stir;

[0130] Step 2, lifting, the organic waste after conditioning and stirring is lifted up by the lifting device 2 and transported to the filter device 3;

[0131] Step 3, filtering, the organic waste transported to the filter device 3 is filtered out by the filter device 3 of the organic waste with a particle size greater than 5mm, and the organic waste less than 5mm is lifted by the pumping device 4 and transported to the biological bed 5 In the feed hopper 521 at the place;

[0132] Step 4, feeding, conveying the organic waste in the hopper 521, and conveying the organ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com