A low-temperature-resistant halogen-free flame-retardant rubber and its preparation method

A low-temperature-resistant rubber technology, which is applied in the field of low-temperature-resistant halogen-free flame-retardant rubber and its preparation, can solve the problems of reducing the low-temperature resistance of rubber materials, and achieve the effects of good low-temperature resistance, convenient use, and small bending radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A method for preparing a low-temperature-resistant rubber with halogen-free flame-retardant properties, comprising the steps of:

[0050] Step 1, taking each component according to parts by weight;

[0051] Step 2. On the open rubber mixer, adjust the roller distance to the specified size (determined according to the amount of rubber mixing), adjust and fix the position of the rubber baffle; put the raw rubber into the roller gap of the open mixer along one side of the roller In the process, the glue is evenly and continuously wrapped on the front roller by means of tamping, rolling, and triangular bagging, leaving an appropriate amount of accumulated glue on the top of the roller distance. After 2-3 minutes of rolling and smelting, a smooth and gap-free Roller glue;

[0052] Step 3. According to the following feeding order, add various raw materials evenly along the axis of the roller in turn. After each feeding, after they are all eaten, cut the left and right 3 / 4 kn...

Embodiment 11~ Embodiment 14

[0084] According to the aforementioned screening results and implementation steps, Example 11-Example 14 and their inspection results are shown in Table 5 and Table 6.

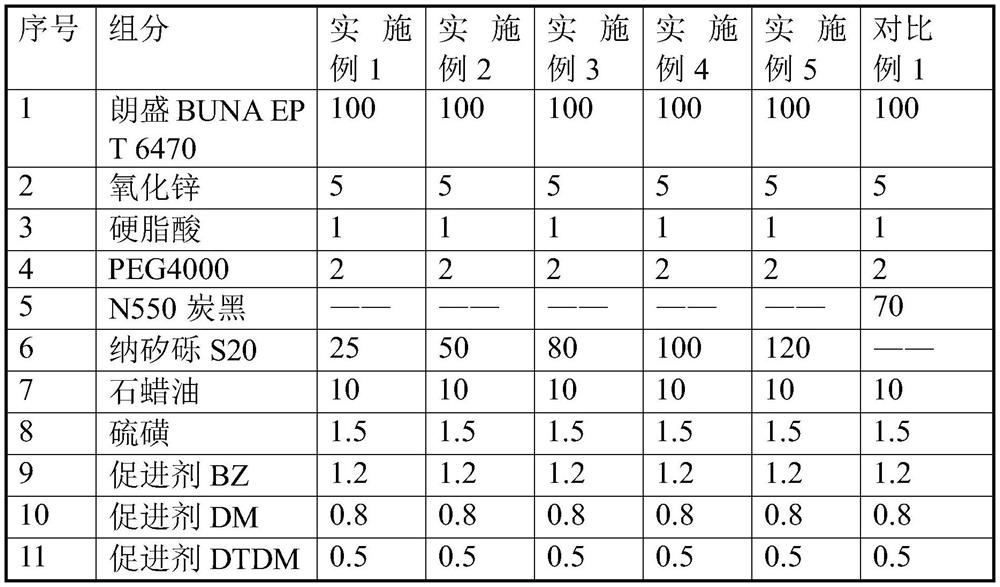

[0085] Table 5 Low-temperature-resistant halogen-free flame-retardant EPDM formulations provided by Examples 11-14

[0086]

[0087]

[0088] Performance Testing:

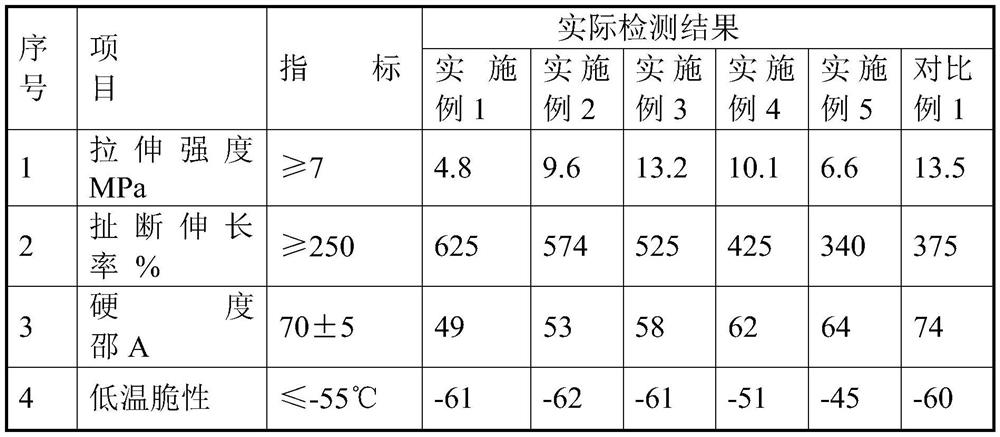

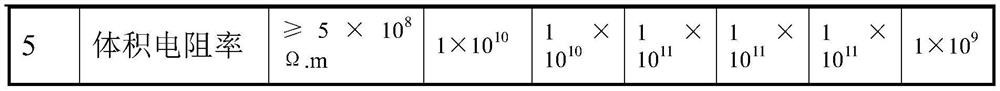

[0089] Embodiment 11-14 is tested, and test result is as shown in table 6:

[0090] The performance test result of the rubber that table 6 embodiment 11-14 provides

[0091]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com