Non-woven fabric with antibacterial effect and preparation method thereof

A technology of antibacterial and sterilized non-woven fabrics, which is applied in the direction of dressing preparations, non-woven fabrics, pharmaceutical formulations, etc., can solve the problems of poor visual sense, poor fit, and ordinary non-woven fabrics do not have sterilization, etc., to achieve The effect of light weight and strong elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

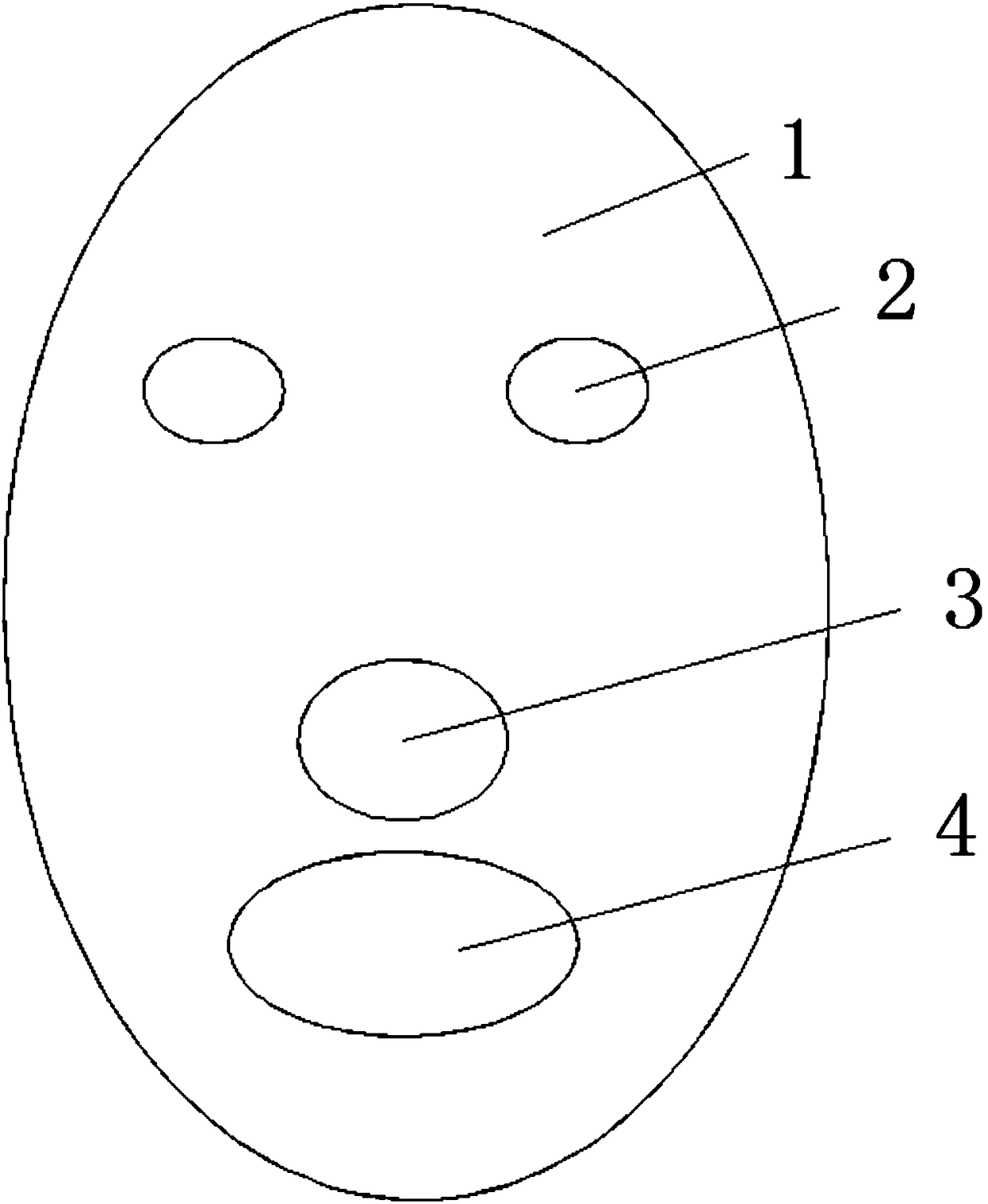

[0037] refer to figure 1 In this embodiment, a non-woven fabric with antibacterial effect is proposed, including a sterilized non-woven fabric main body 1, and two symmetrically arranged eyelets 2 are arranged on the top of one side of the sterilized non-woven fabric main body 1, And one side of the sterilized non-woven fabric main body 1 is provided with a nostril 3 located below the eyehole 2, and a mouth hole 4 arranged on the sterilized non-woven fabric main body 1 is provided below the nostril 3;

[0038] The main body 1 of the sterilized non-woven fabric includes raw materials according to the following proportions by weight: cupro fibers, cellulose fibers and copper-modified polyester fibers, and cupro fibers, cellulose fibers and copper-modified polyester fibers The mass percent of the fiber is: 30-40% of the cupro ammonia silk fiber, 30-40% of the cellulose fiber and 20-30% of the copper modified polyester fiber.

[0039] This embodiment also discloses a method for p...

Embodiment 2

[0062] refer to figure 1 In this embodiment, a non-woven fabric with antibacterial effect is proposed, including a sterilized non-woven fabric main body 1, and two symmetrically arranged eyelets 2 are arranged on the top of one side of the sterilized non-woven fabric main body 1, And one side of the sterilized non-woven fabric main body 1 is provided with a nostril 3 located below the eyehole 2, and a mouth hole 4 arranged on the sterilized non-woven fabric main body 1 is provided below the nostril 3;

[0063] The main body 1 of the sterilized non-woven fabric includes raw materials according to the following proportions by weight: cupro fibers, cellulose fibers and copper-modified polyester fibers, and cupro fibers, cellulose fibers and copper-modified polyester fibers The mass percent of the fiber is: 30-40% of the cupro ammonia silk fiber, 30-40% of the cellulose fiber and 20-30% of the copper modified polyester fiber. In this embodiment, the mass percentages of the cupro ...

Embodiment 3

[0087] refer to figure 1 In this embodiment, a non-woven fabric with antibacterial effect is proposed, including a sterilized non-woven fabric main body 1, and two symmetrically arranged eyelets 2 are arranged on the top of one side of the sterilized non-woven fabric main body 1, And one side of the sterilized non-woven fabric main body 1 is provided with a nostril 3 located below the eyehole 2, and a mouth hole 4 arranged on the sterilized non-woven fabric main body 1 is provided below the nostril 3;

[0088] The main body 1 of the sterilized non-woven fabric includes raw materials according to the following proportions by weight: cupro fibers, cellulose fibers and copper-modified polyester fibers, and cupro fibers, cellulose fibers and copper-modified polyester fibers The mass percent of the fiber is: 30-40% of the cupro ammonia silk fiber, 30-40% of the cellulose fiber and 20-30% of the copper modified polyester fiber. In this embodiment, the mass percentages of the cupro ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com