Open-width alkali weight reduction machine

A technology of alkali reduction and open width, applied in the field of alkali reduction machine, can solve the problems of concentration change, different hand feeling, large amount of processing solution, etc., to achieve the effect of reducing consumption, keeping the liquor ratio consistent, and keeping the concentration unchanged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

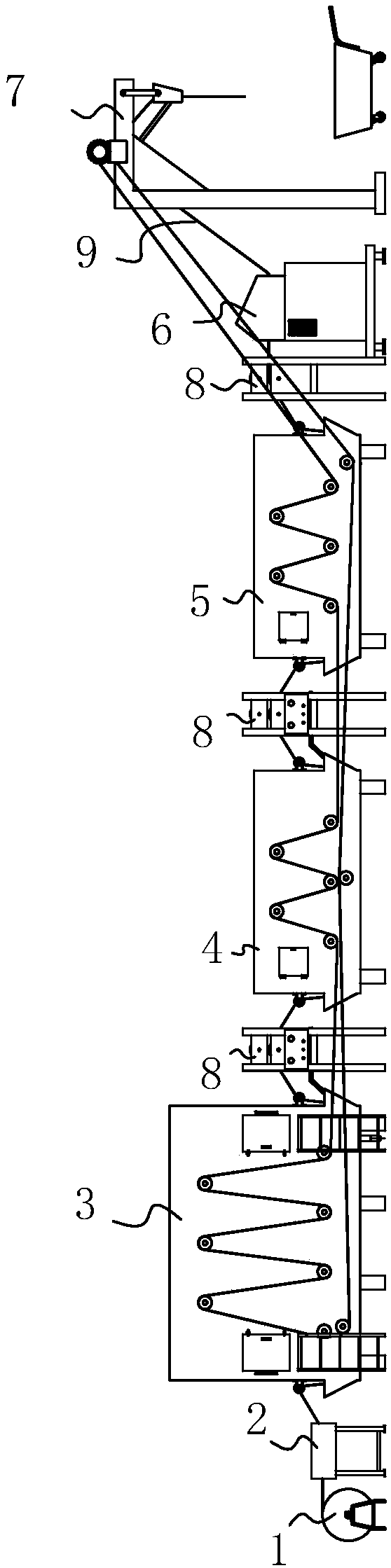

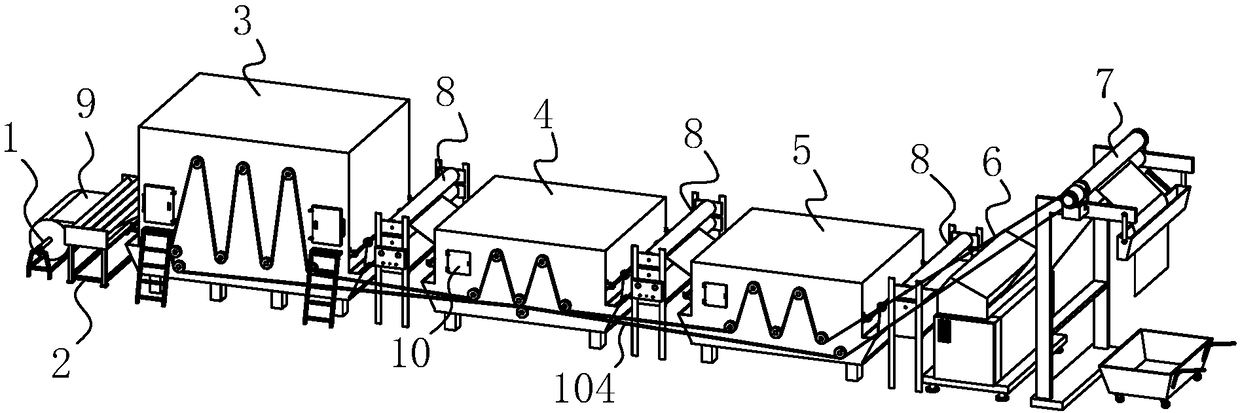

[0041] refer to Figure 1 to Figure 12 Further explanations are given on the open-width alkali weight reducer.

[0042] An open-width alkali weight reducing machine, combined with figure 1 and figure 2 As shown, it includes a cloth feeding device 1 for outputting the gray cloth 9, a tensioning device 2 for ensuring the tension state of the gray cloth 9, an alkali treatment unit 3 for spraying lye on the gray cloth 9, and a device for promoting hydrolysis. The heating unit 4 of the reaction, the steam washing unit 5 for cleaning the gray cloth 9, the oven 6 for drying the gray cloth 9, and the arrangement device 7 for collecting the folded gray cloth 9, wherein, between the alkali treatment unit 3 and the heating unit 4 , between the heating unit 4 and the steaming and washing unit 5 and between the steaming and washing unit 5 and the oven 6 are provided with a two-roll padding car 8 for rolling off excess liquid on the gray cloth 9 .

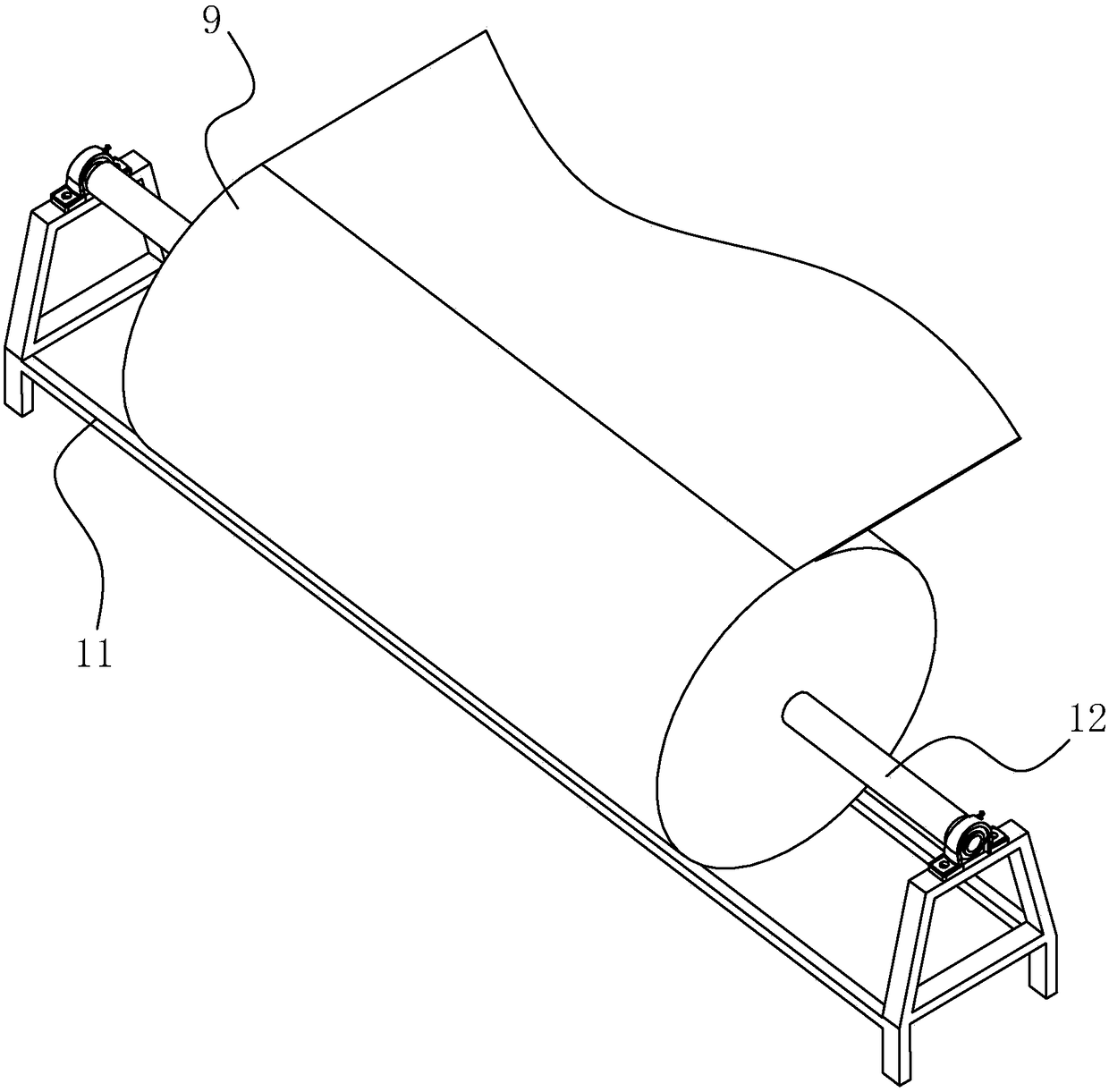

[0043] combine figure 2 and image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com