Automated planting greenhouse temperature and humidity control system and method thereof

A temperature and humidity control and greenhouse technology, applied in the field of temperature and humidity monitoring in greenhouses, can solve problems such as increased maintenance and debugging difficulties, unfavorable digital signal integrity performance, loss of analog signals, etc., to overcome erosion and reduce heat accumulation , the effect of enhancing mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below with reference to the accompanying drawings and embodiments.

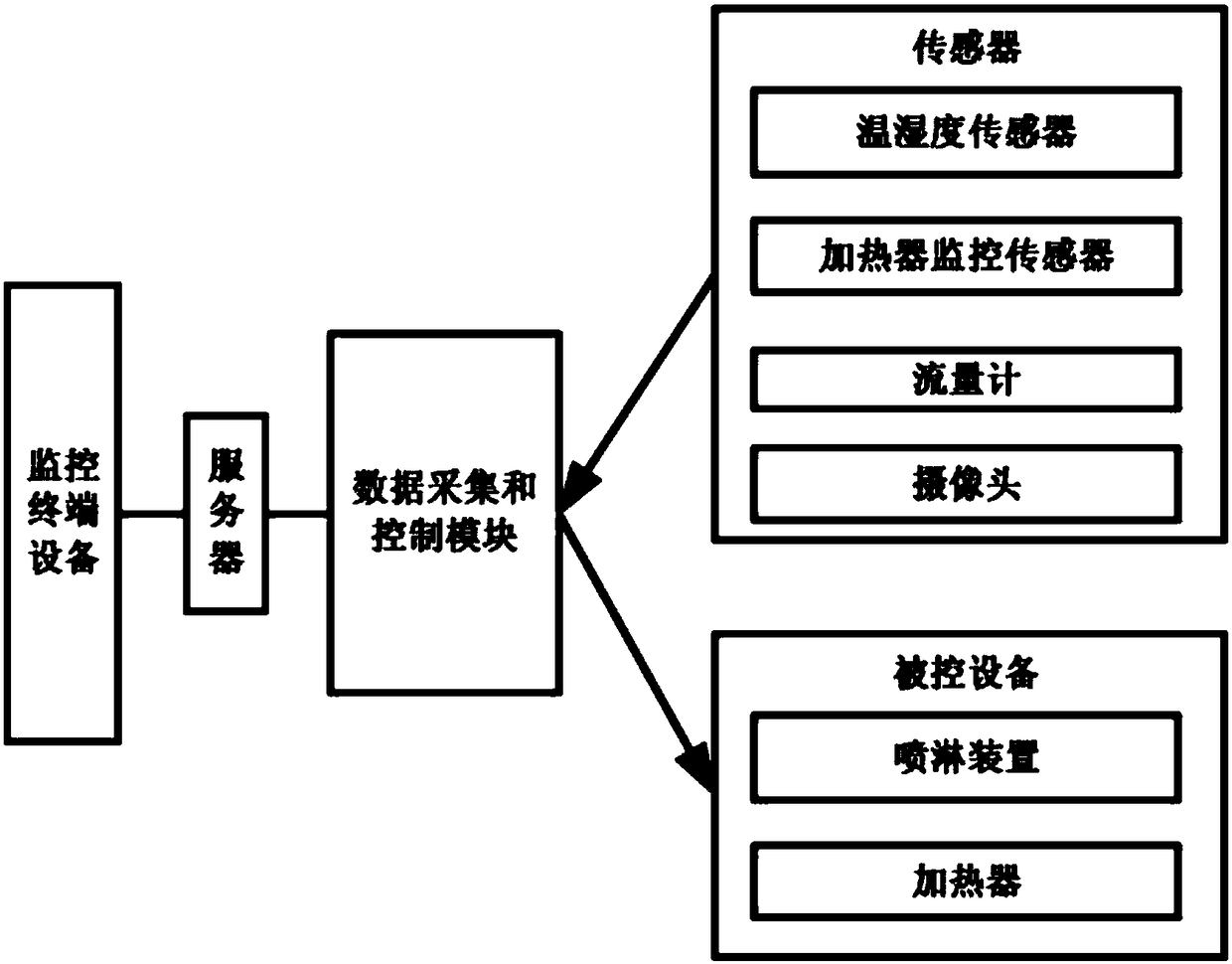

[0062] like Figure 1-Figure 4 As shown in the figure, the automatic planting greenhouse temperature and humidity control system includes sensors and controlled equipment. Both the sensor and the controlled equipment are connected to the microcontroller; the microcontroller is connected to the server; the monitoring terminal equipment and the server exchange information through wired or wireless means .

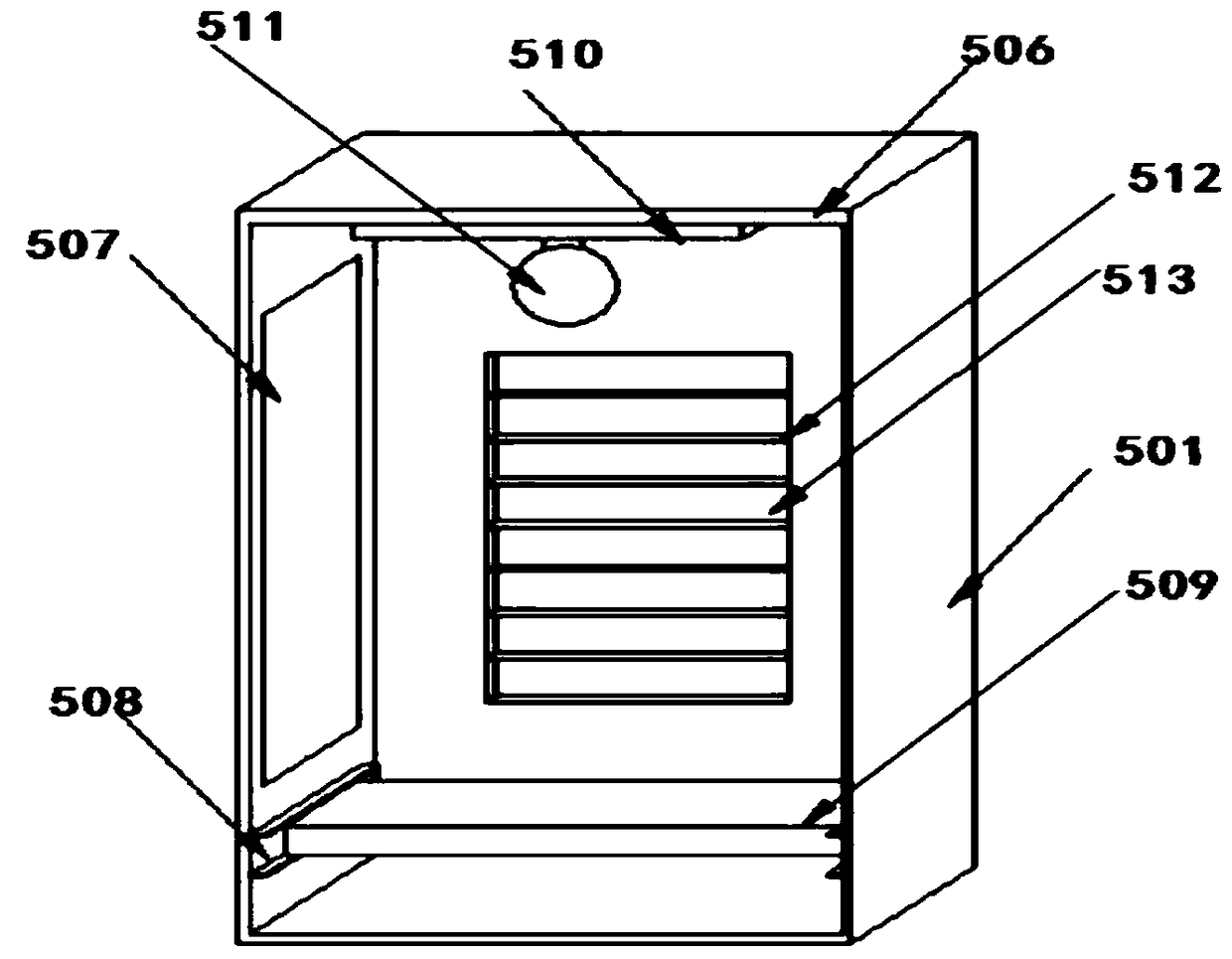

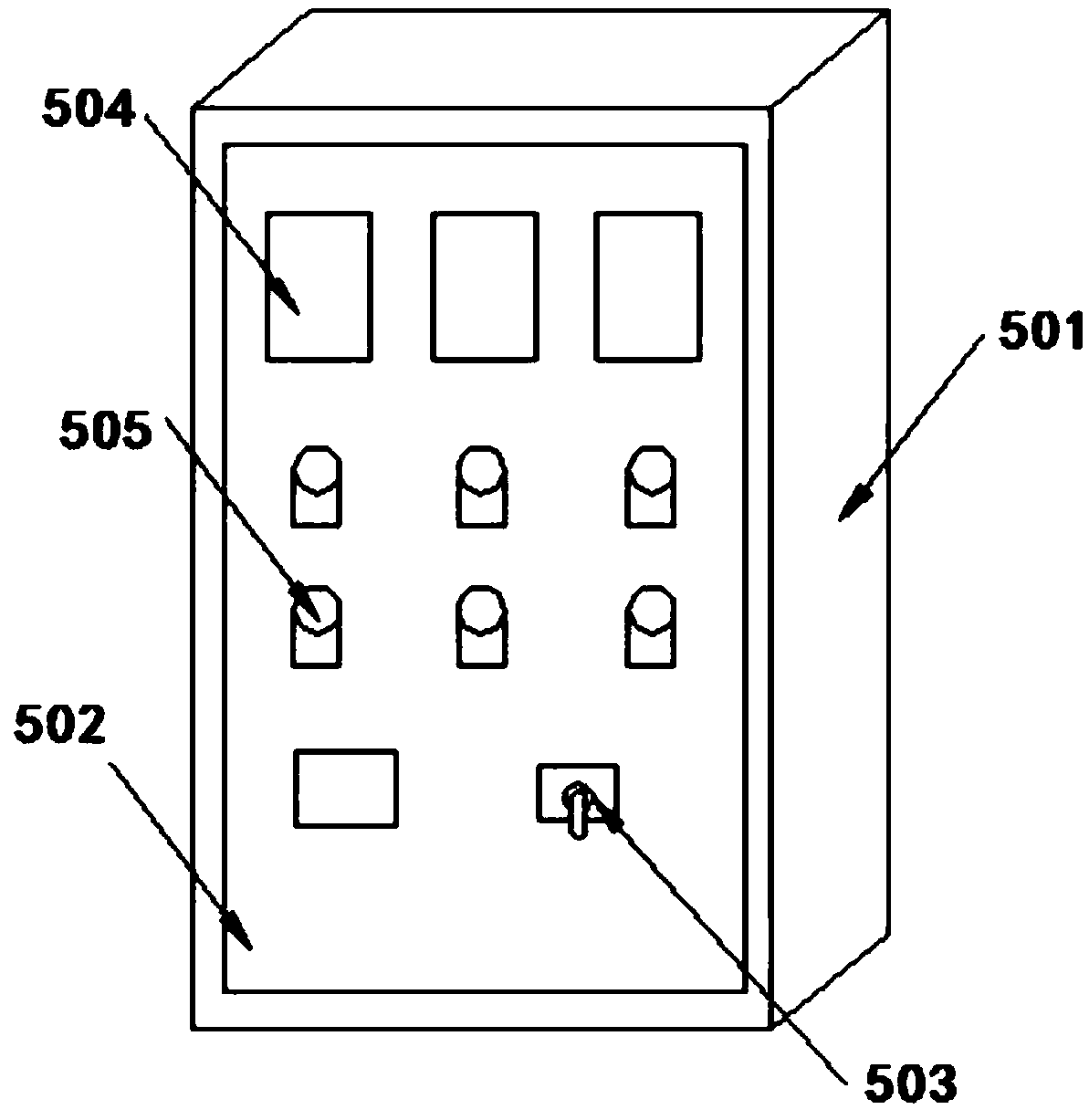

[0063] The sensor and the controlled device are connected with the microcontroller via a wire, and the microcontroller is arranged in the controller chassis. The controller chassis includes a box body 501, and the front side of the box body 501 has a through hole. A cover plate 502 is pivoted where the through cavity is located. The cover plate 502 is provided with a circuit breaker 503, a cavity 504 for storing the galvanometer, and an LED-505. A cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com