Feed material mixer for livestock feed processing

A feed raw material, mixing and stirring technology, applied in the directions of feed, mixer, mixer accessories, etc., can solve the problems of low work efficiency, low mixing efficiency of feed raw materials, large labor volume, etc., to improve mixing efficiency, reduce labor volume, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

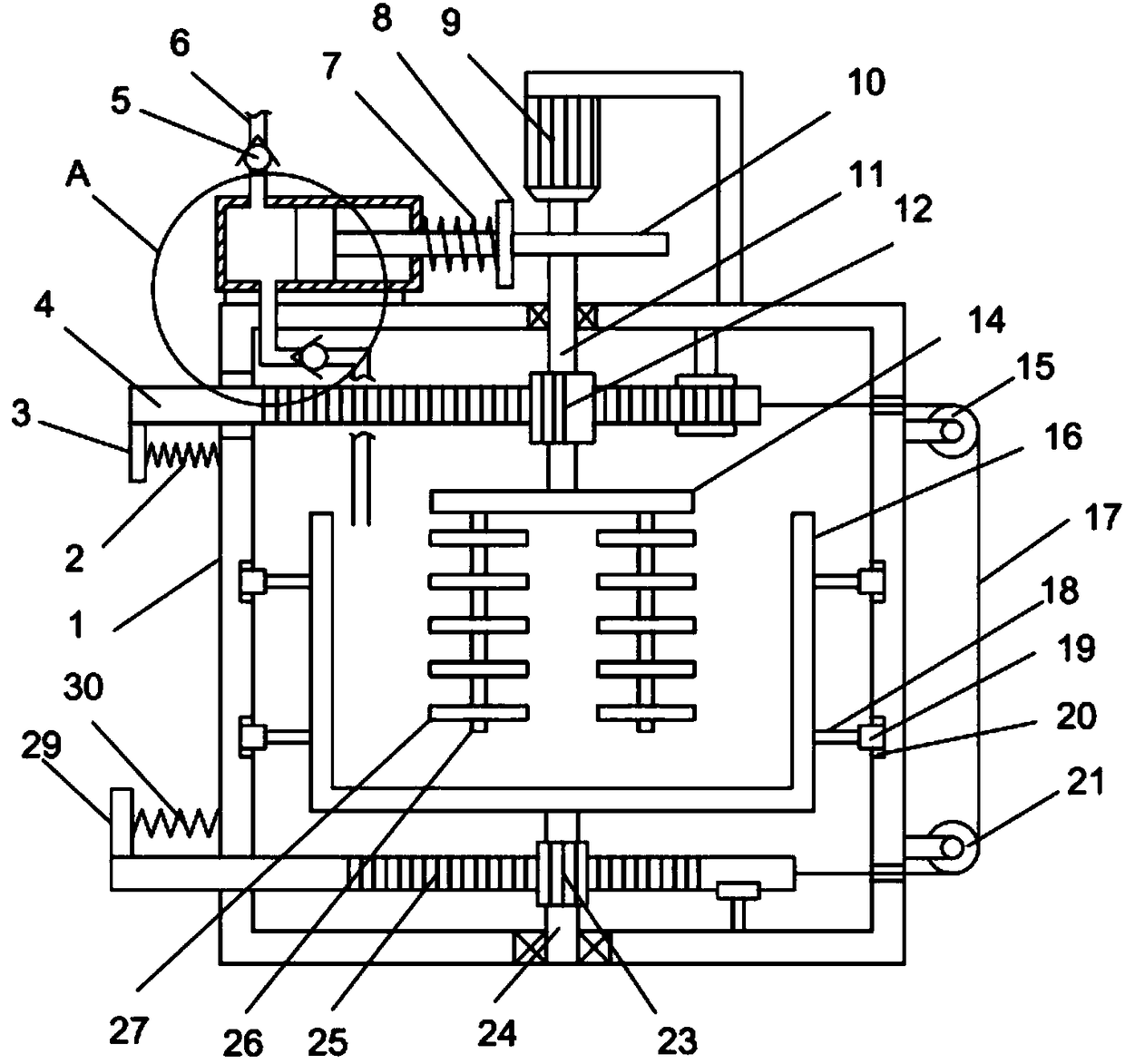

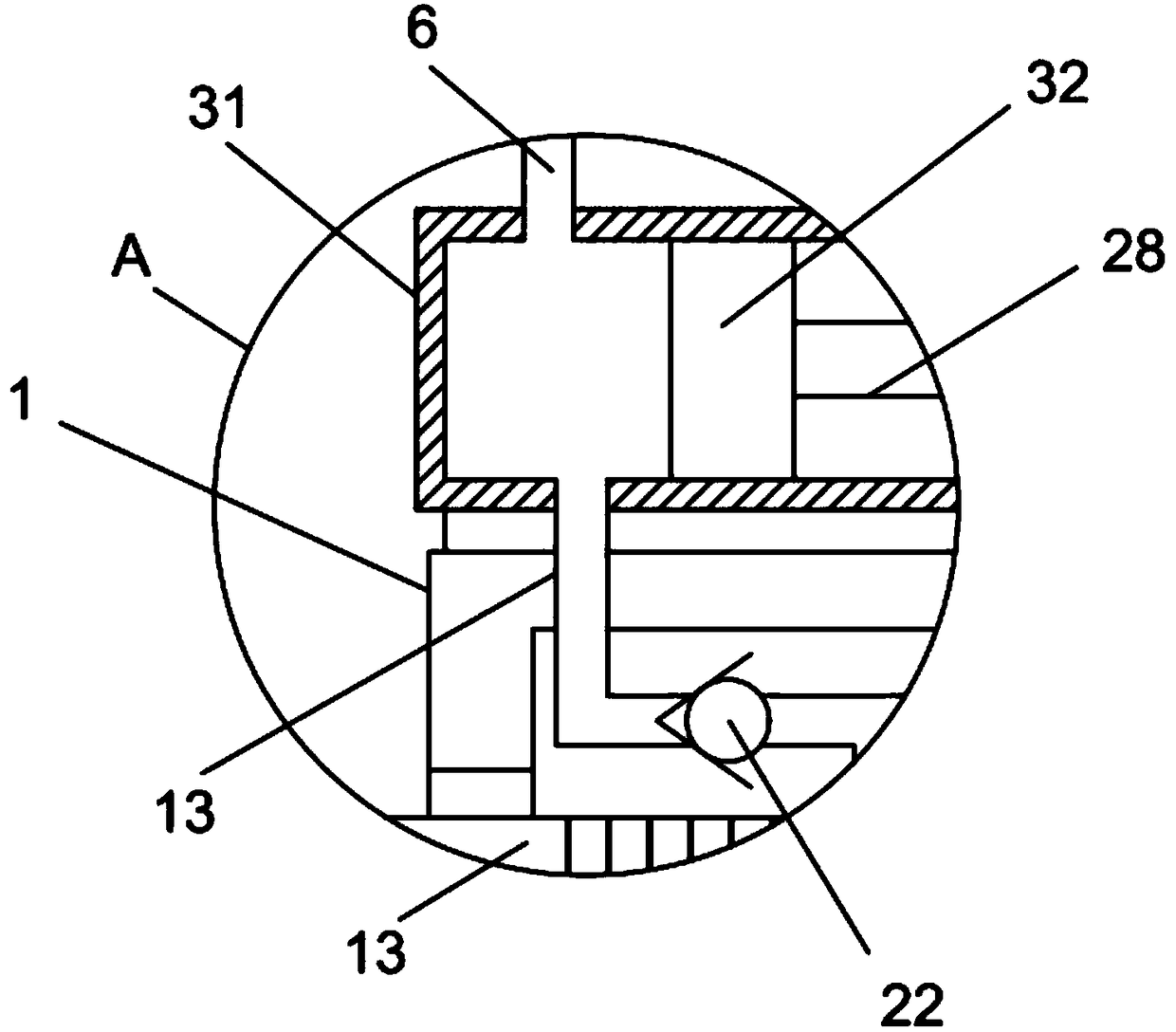

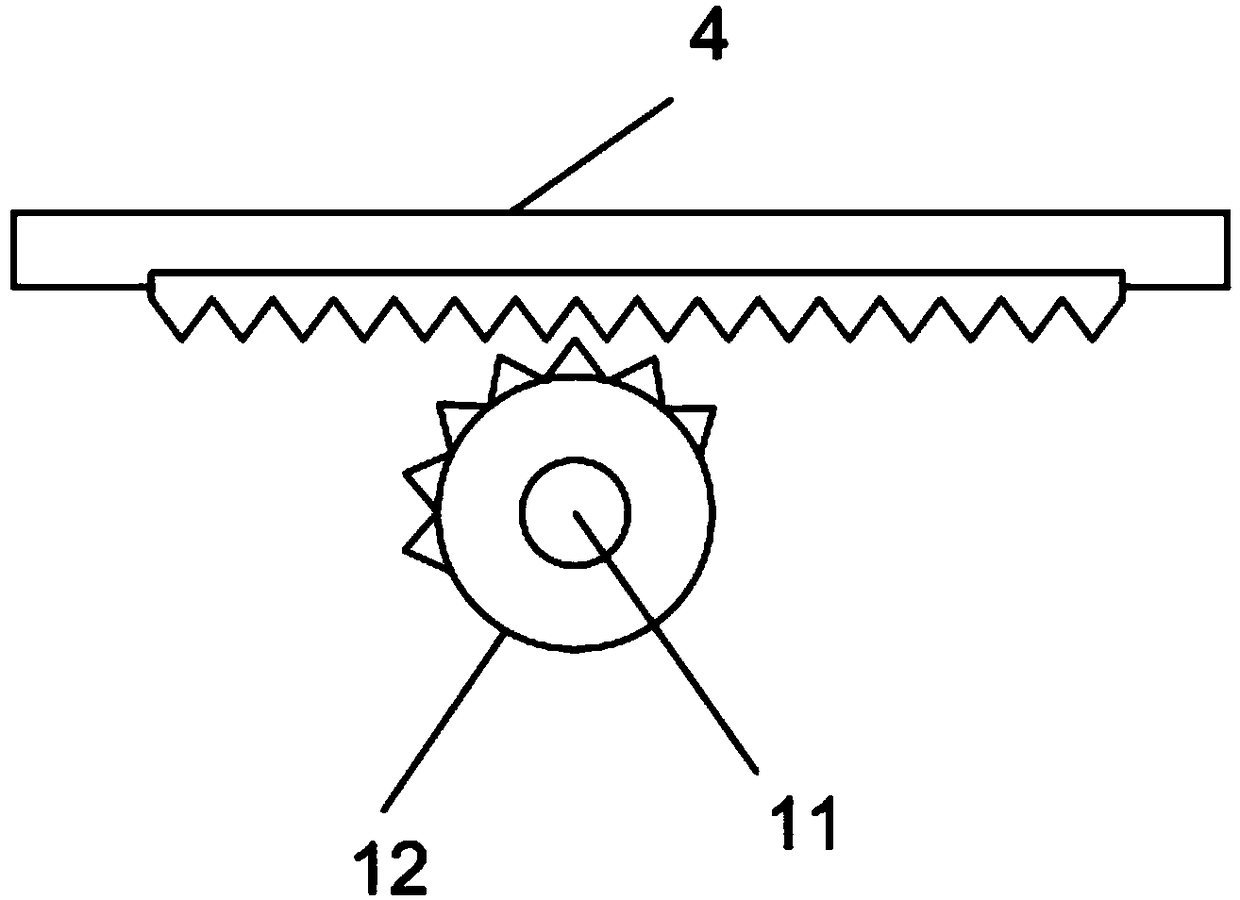

[0020] see Figure 1-3 , a feed raw material mixing device for livestock feed processing, comprising an operation box 1 and a mixing bucket 16, the top of the operation box 1 is fixedly installed with a drive motor 9 upside down through a bracket, and the output shaft of the drive motor 9 is coaxially fixedly installed with an extension To the mixing barrel 16 inside the operation box 1, a compression cylinder 31 is fixedly installed on the operation box 1, and a piston head 32 is slidably arranged in the compression cylinder 31, and a piston rod 28 is fixedly installed on the right end of the piston head 32 horizontally. The right end is vertically and fixedly installed with a pressing plate 8, the surface of the drive shaft 11 is sheathed and fixedly installed with a cam 10 abutting against the pressing plate 8, and the movable sleeve of the piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com