Method for synthesizing Ti3B2N by adopting Pb fluxing agent

A technology of flux and mixing materials, which is applied in chemical instruments and methods, boron compounds, nitrogen compounds, etc., can solve the problems of high synthesis temperature, high production cost at high temperature, and immature synthesis technology, so as to reduce the synthesis temperature and synthesis method. Simple and easy to operate, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The present embodiment provides a kind of adopting Pb flux to synthesize Ti 3 B 2 N method to synthesize Ti 3 B 2 The method of N includes the following steps:

[0050] 1) Weigh TiH respectively 2 Powder, amorphous B powder and hexagonal BN powder, spare;

[0051] and TiH 2 The molar ratio of TiH powder, amorphous B powder and hexagonal BN powder 2 :B:BN=3:1:1;

[0052] 2) the TiH taken in step 1) 2 Powder, amorphous B powder and hexagonal BN powder are put into a container and mixed and stirred evenly to obtain a mixture;

[0053] TiH 2 Powder, amorphous B powder and hexagonal BN powder are put into the container and mixed and stirred evenly. The process is: in TiH 2 powder, amorphous B powder, and hexagonal BN powder were mixed and stirred, then absolute ethanol was added, mixed and stirred for 18 hours, and then dried naturally. Wherein, the addition amount of absolute ethanol must satisfy that this absolute ethanol liquid level completely submerges higher...

Embodiment 2

[0061] The difference between this embodiment and embodiment 1 is: TiH 2 powder, amorphous B powder, hexagonal BN powder, the molar ratio of the three raw materials TiH 2 :B:BN=2.5:1.3:1.3. Others are the same as in Example 1.

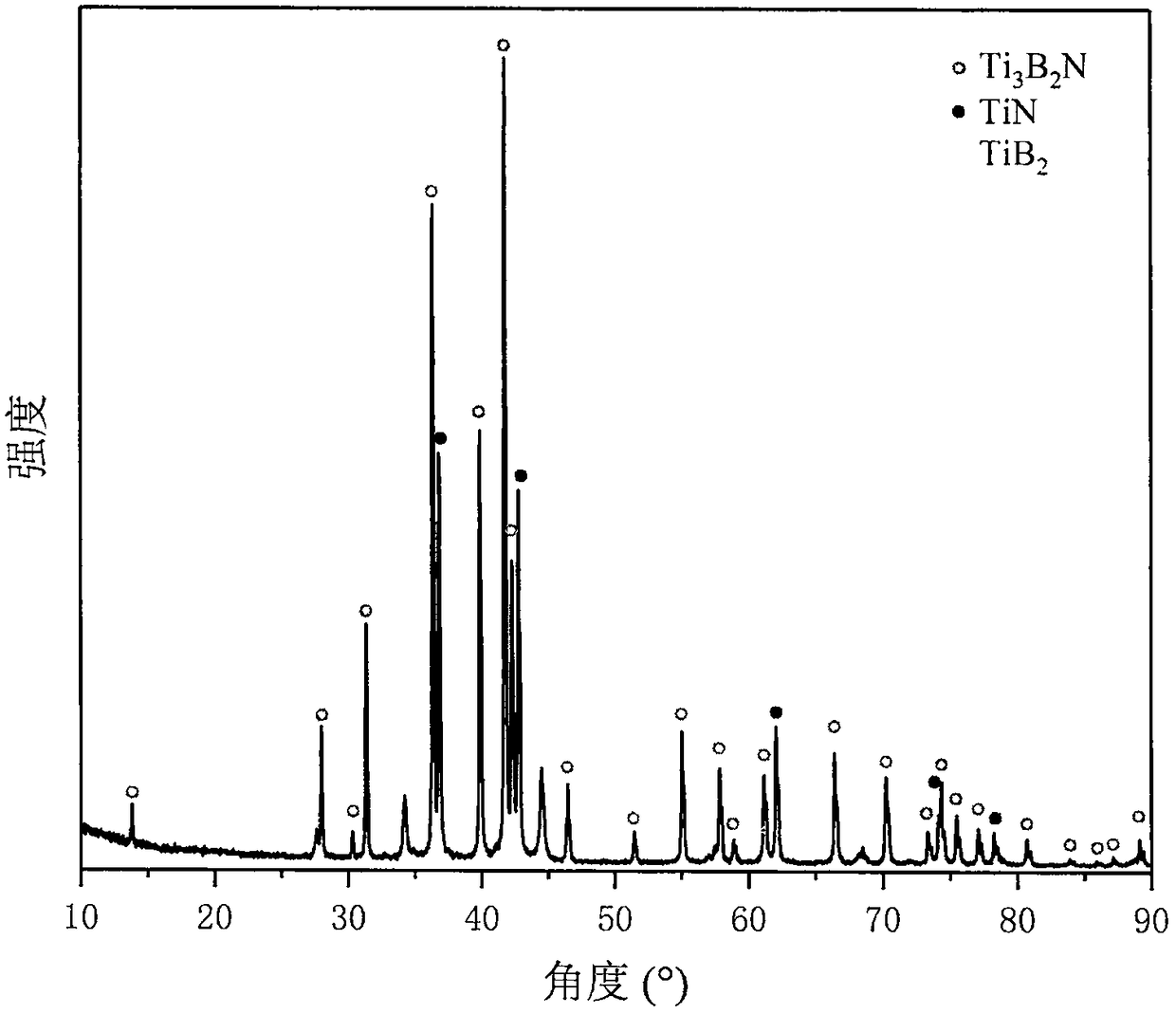

[0062] The XRD pattern of the product prepared in this embodiment is shown in Figure 4 . Although still containing Ti 3 B 2 N.TiB 2 and TiN three phases, but the comparison between Example 2 and Example 1 shows that in the sample synthesized in Example 2, Ti 3 B 2 The content of N is reduced compared with that in Example 1.

Embodiment 3

[0064] The difference between this embodiment and Embodiment 1 is that the heating temperature of the quartz tube containing the sample is 600°C. Others are the same as in Example 1.

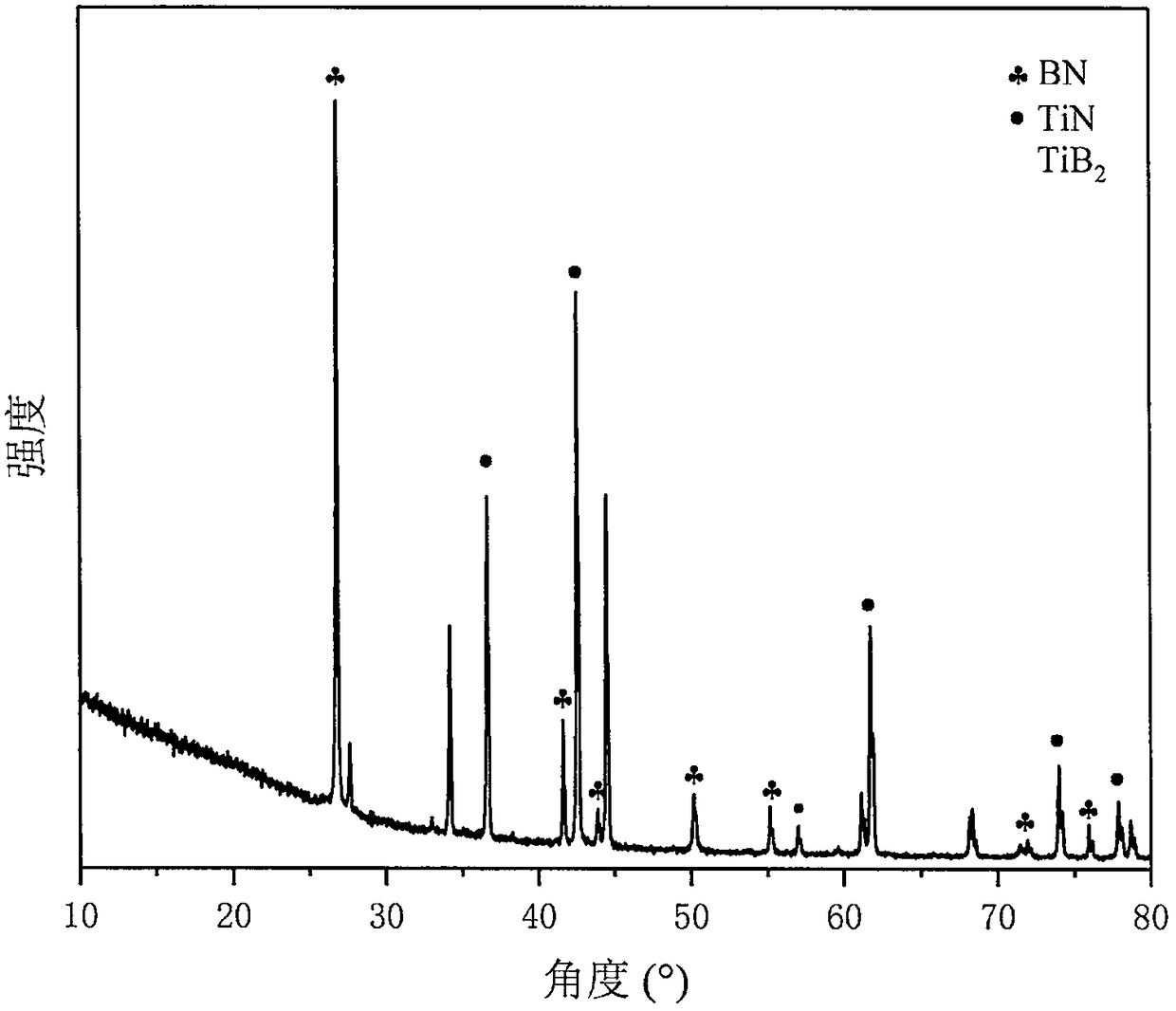

[0065] The XRD pattern of the product prepared in this embodiment is shown in Figure 5 . Although this example still contains Ti 3 B 2 N.TiB 2 and TiN three phases, but in the sample synthesized in Example 3, Ti 3 B 2 The content of N is reduced compared with that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com