Method for heating and desalting seawater based on gas-liquid interface

A gas-liquid interface, seawater technology, applied in chemical instruments and methods, heating water/sewage treatment, seawater treatment, etc., can solve problems such as heat loss, reduce seawater desalination efficiency, etc., achieve the effect of reducing heat loss and accelerating seawater distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Add 10mg of granular carbon nanotubes into a 100mL beaker filled with 40mL of artificial seawater, and ultrasonically crush them in a biosafer650-92 ultrasonic cell pulverizer to obtain a suspension of carbon nanotubes. The main parameters of the ultrasonic cell pulverizer are: ultrasonic Power 650W, ultrasonic power accuracy 75%, horn (mm) , temperature 30°C, ultrasound 5s, interval 5s, total time 60min. SEM images of carbon nanotubes before and after ultrasonic treatment figure 1 and 2 shown.

[0031] (2) Vacuum filter the suspension of carbon nanotubes on a 4 cm diameter round dust-free paper (vacuum degree is -0.015 to -0.02 MPa), and dry the dust-free paper at room temperature for 24 hours.

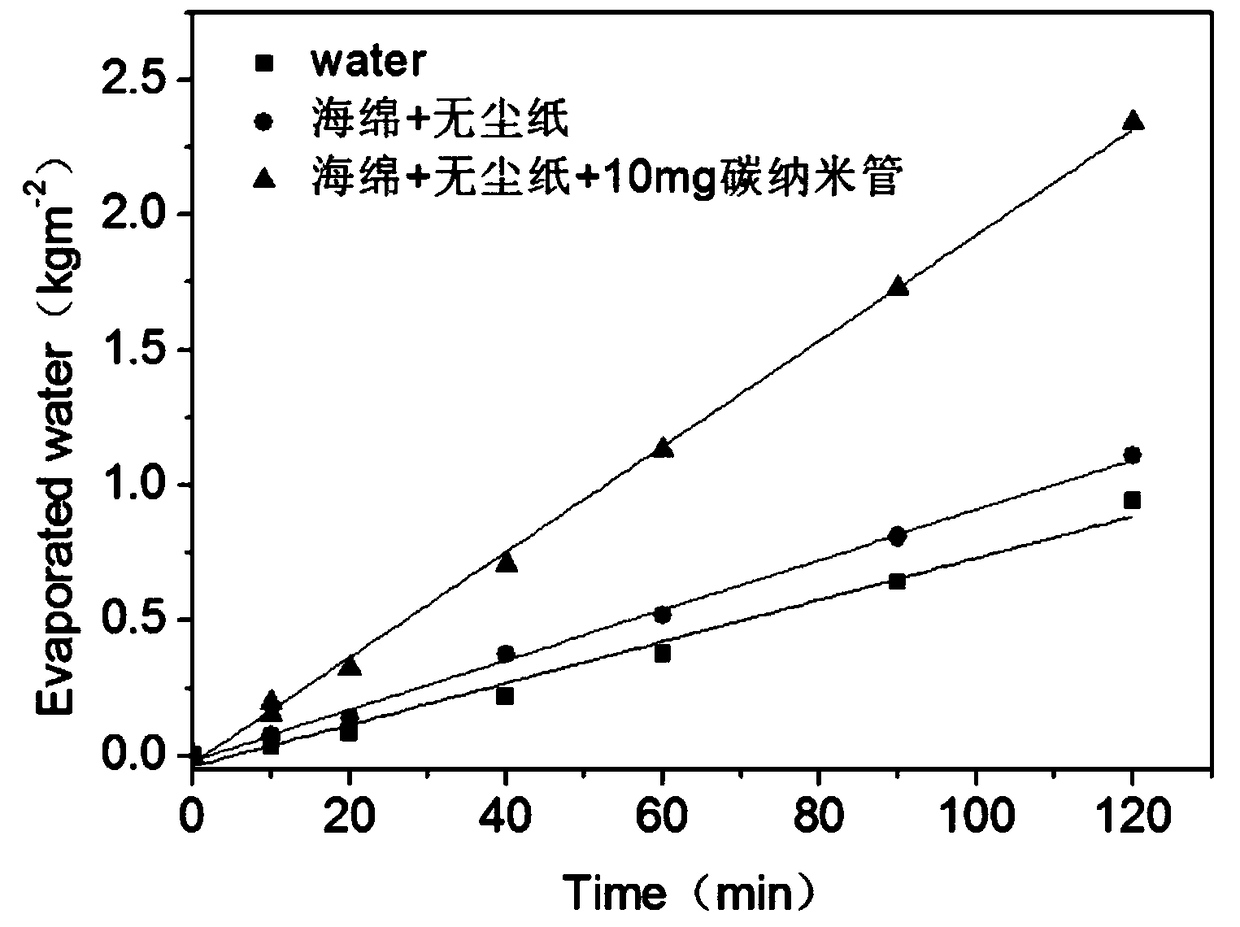

[0032] (3) Paste the dry dust-free paper with 10 mg of carbon nanotubes attached to the surface of a cylindrical polyurethane sponge soaked in water (bottom diameter 4cm, thickness 2cm), and float the carbon nanotube-dust-free paper-sponge combination On the surface o...

Embodiment 2~6

[0040] (1) Add 5, 7.5, 10, 15, and 20 mg of granular carbon nanotubes into five 100 mL beakers filled with 40 mL of artificial seawater, and ultrasonically crush them in a biosafer650-92 ultrasonic cell pulverizer to obtain carbon nanotube suspensions. liquid, the main parameters of the ultrasonic cell pulverizer are: ultrasonic power 650W, ultrasonic power accuracy 75%, horn (mm) , temperature 30°C, ultrasound 5s, interval 5s, total time 60min.

[0041] (2) Vacuum filter the suspension of carbon nanotubes on a 4 cm diameter round dust-free paper (vacuum degree is -0.015 to -0.02 MPa), and dry the dust-free paper at room temperature for 24 hours.

[0042] (3) Paste the dry dust-free paper with carbon nanotubes attached on the surface of a cylindrical polyurethane sponge (bottom diameter 4cm, thickness 2cm) soaked in water, and float the sponge-dust-free paper-carbon nanotube combination on On the water surface of a 50ml beaker (diameter 4cm) filled with artificial seawater, t...

Embodiment 7

[0046] (1) Add 10mg of granular carbon nanotubes into a 100mL beaker filled with 40mL of artificial seawater, and ultrasonically crush them in a biosafer650-92 ultrasonic cell pulverizer to obtain a suspension of carbon nanotubes. The main parameters of the ultrasonic cell pulverizer are: ultrasonic Power 650W, ultrasonic power accuracy 75%, horn (mm) , temperature 30°C, ultrasound 5s, interval 5s, total time 60min.

[0047] (2) Vacuum filter the suspension of carbon nanotubes on a round dust-free paper with a diameter of 4 cm (vacuum degree is -0.015 to -0.02 MPa), and dry the dust-free paper at room temperature for 24 hours;

[0048] (3) Paste the dry dust-free paper with 10 mg of carbon nanotubes attached to the surface of a cylindrical polyurethane sponge soaked in water (bottom diameter 4cm, thickness 2cm), and float the sponge-dust-free paper-carbon nanotube combination On the surface of a 50ml beaker (diameter 4cm) filled with artificial seawater, the beaker is placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com