Anti-leakage cold storage agent and preparation method thereof

A cold storage agent and anti-leakage technology, which is applied in the direction of chemical instruments and methods, reagents, educts, etc., can solve the problems of contaminating pharmaceutical biological products, easy leakage, and potential safety hazards of phase-change cold storage materials, etc., and achieves convenient preparation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) the mass fraction is 1% K 2 HPO 4 The aqueous solution is added dropwise to an aqueous solution of polyethylene glycol (number average molecular weight: 600) with a mass fraction of 1%, and stirred and mixed at room temperature to obtain a solution A. The K 2 HPO 4 The volume ratio of polyethylene glycol solution is 1:100.

[0021] (2) Slowly add n-tetradecane dropwise to solution A, and stir at room temperature for 1 h to obtain solution B. The mass ratio of n-tetradecane in solution B to solution A is 90:1.

[0022] (3) At room temperature, mix sodium carboxymethyl cellulose aqueous solution (1% by mass fraction) and sodium lauryl sulfate (1% by mass fraction) at a volume ratio of 1:1, and stir for 30 minutes to obtain solution C.

[0023] (4) Add solution C dropwise to solution B, and continue stirring at room temperature for 1 hour to obtain a leak-proof cool storage agent. The volume ratio of solution C and solution B is 1:0.8.

[0024] The cold storage ...

Embodiment 2

[0026] (1) the mass fraction is 1% K 2 HPO 4 The aqueous solution is added dropwise to an aqueous solution of polyethylene glycol (number average molecular weight: 10,000) with a mass fraction of 1%, and stirred and mixed at room temperature to obtain a solution A. The K 2 HPO 4 The volume ratio of polyethylene glycol solution is 1:100.

[0027] (2) Slowly add n-tetradecane dropwise to solution A, and stir at room temperature for 1 h to obtain solution B. The mass ratio of n-tetradecane in solution B to solution A is 90:1.

[0028] (3) At room temperature, mix sodium carboxymethyl cellulose aqueous solution (2% by mass fraction) and sodium lauryl sulfate (2.5% by mass fraction) at a volume ratio of 2:1, and stir for 30 minutes to obtain solution C.

[0029] (4) Add solution C dropwise to solution B, and continue stirring at room temperature for 1 hour to obtain a leak-proof cool storage agent. The volume ratio of solution C and solution B is 1:2.6.

[0030] The cold sto...

Embodiment 3

[0032] (1) the mass fraction is 1% K 2 HPO 4 The aqueous solution is added dropwise to an aqueous solution of polyethylene glycol (number-average molecular weight: 8000) with a mass fraction of 1%, and stirred and mixed at room temperature to obtain a solution A. The K 2 HPO 4 The volume ratio of polyethylene glycol solution is 1:100.

[0033] (2) Slowly add n-tetradecane dropwise to solution A, and stir at room temperature for 1 h to obtain solution B. The mass ratio of n-tetradecane in solution B to solution A is 90:1.

[0034] (3) At room temperature, mix sodium carboxymethyl cellulose aqueous solution (1.6% by mass fraction) and sodium lauryl sulfate (2% by mass fraction) at a volume ratio of 1:1, and stir for 30 minutes to obtain solution C.

[0035] (4) Add solution C dropwise to solution B, and continue stirring at room temperature for 1 hour to obtain a leak-proof cool storage agent. The volume ratio of solution C and solution B is 1:0.8.

[0036] The cold stora...

PUM

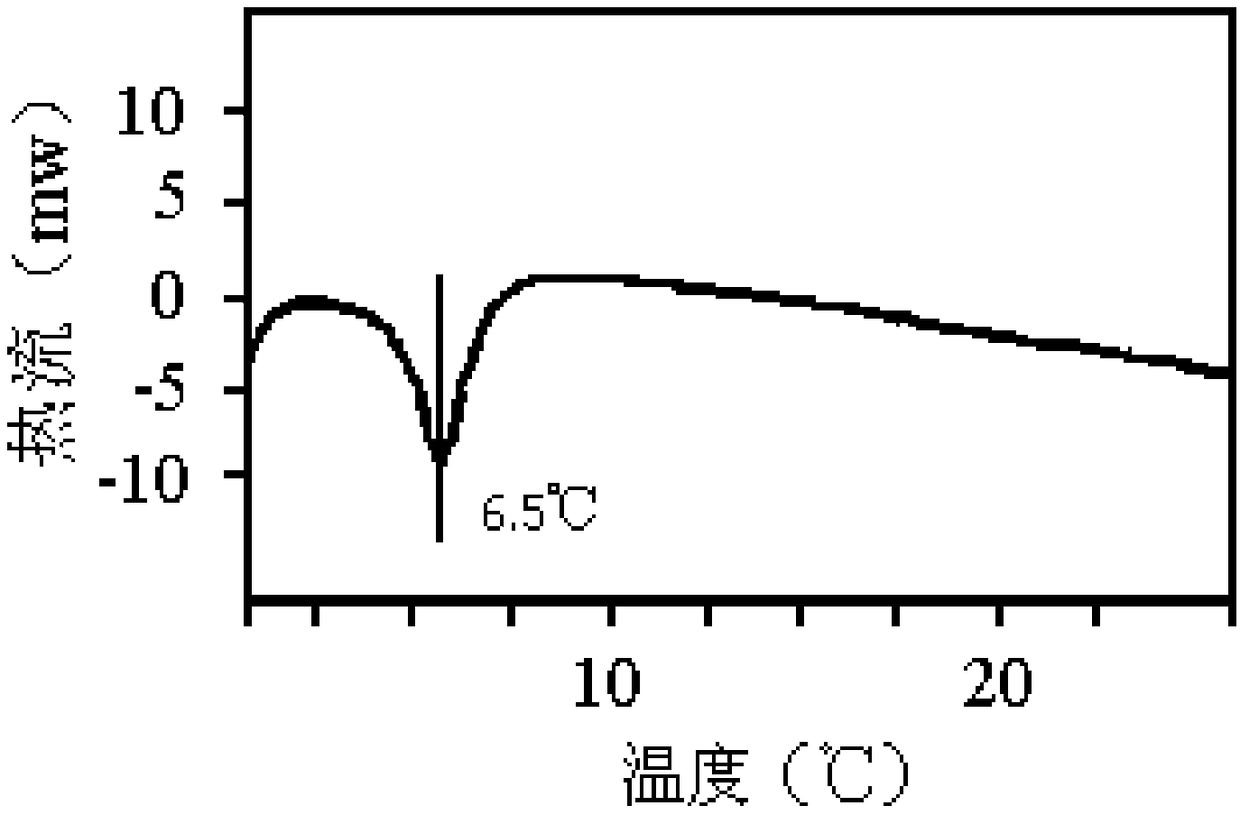

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com