Biomass-based surfactant containing hogwash oil extract and preparation method thereof

A technology based on surfactants and biomass, which is applied in the direction of polymer surface active compounds, surface active detergent compositions, nonionic surface active compounds, etc., to achieve the effect of improving hydrolysis efficiency, improving utilization value, and improving decontamination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

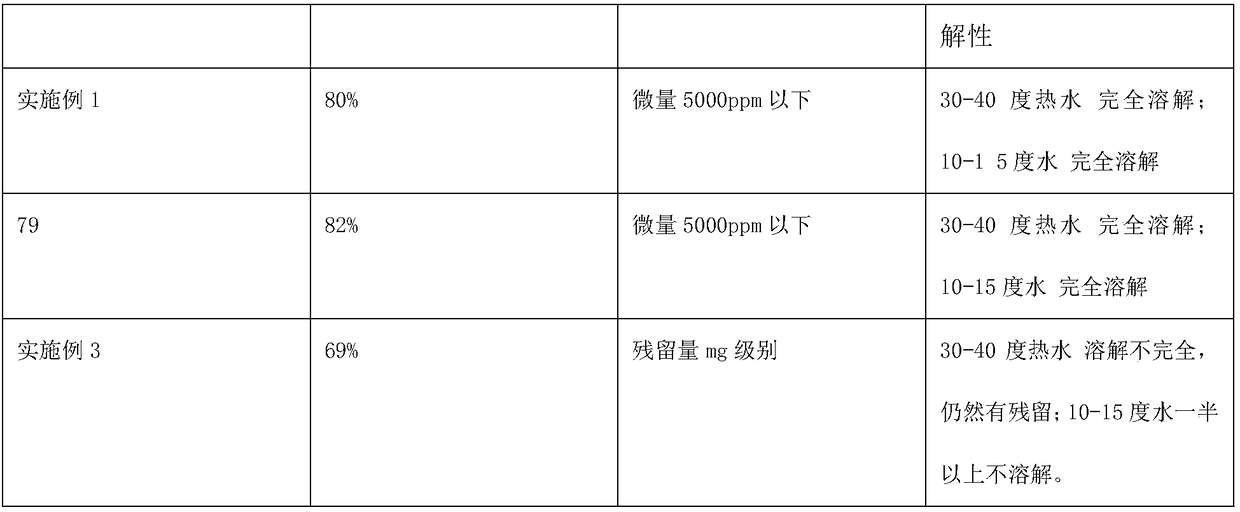

Embodiment 1

[0027] Biomass-based surfactant. The main raw materials of the biomass-based surfactant include: 15 parts by weight of palm kernel oil fatty acid obtained after hydrolysis of natural palm kernel oil, 80 parts by weight of palm oil fatty acid obtained by hydrolysis of palm oil, and 80 parts by weight of palm oil fatty acid obtained by hydrolysis of coconut oil. 15 parts by weight of coconut oil fatty acid, 15 parts by weight of fatty acid extracted from waste oil; then the above four fatty acids are mixed with caustic soda to produce soap grains.

[0028] Preparation steps include:

[0029] (1) According to the formula ratio, the main raw materials of biomass-based surfactants: palm kernel oil fatty acid obtained by hydrolysis of natural palm kernel oil, palm oil fatty acid obtained by hydrolysis of palm oil, coconut oil fatty acid obtained by hydrolysis of coconut oil and waste oil Extract fatty acid and mix evenly with surfactant, builder, water and other ingredients;

[003...

Embodiment 2

[0033] Biomass-based surfactant, the main raw materials of the biomass-based surfactant include: 17 parts by weight of palm kernel oil fatty acid obtained after hydrolysis of natural palm kernel oil, 80 parts by weight of palm oil fatty acid obtained by hydrolysis of palm oil, and 80 parts by weight of palm oil fatty acid obtained by hydrolysis of coconut oil. 17 parts by weight of coconut oil fatty acid and 17 parts by weight of fatty acid extracted from waste oil; then the above four fatty acids are mixed with caustic soda to produce soap grains. Preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com